Is 18 months fast for major manufacturers to decide, test and deploy a new CAM software, or tectonically slow in today’s high-paced, technology-driven world?

Reading between the lines of its press release, where Open Mind Technologies rightly celebrates BMW’s take-up of its HyperMill CAD/CAM software, it offers an interesting view of the timescale and processes needed to implement such a purchase within a major enterprise.

The press release suggests that HyperMill is now available across all of the automotive giant’s “departments and plants all over the world”, and that the process to reach such a stage is further detailed as having taken 18 months.

“18 months ago, the central IT department of the BMW Group began searching for a new CAD/CAM system,” reads the release. “The goal was to find a CAD/CAM solution with a high level of coverage for the many different NC application areas in the specialist departments.

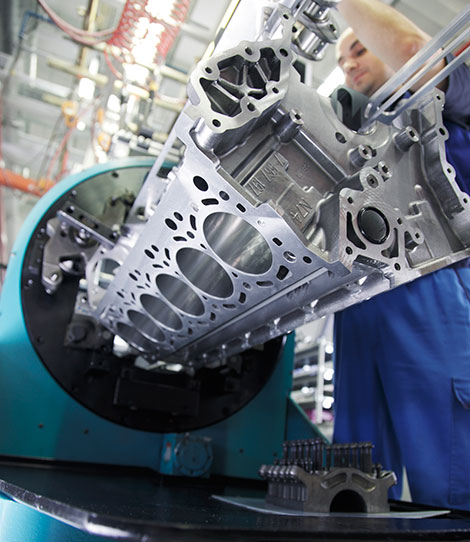

HyperMill will be deployed across all of BMW’s ‘departments and plants’ across the world

“This resulted in a comprehensive technical evaluation and a cost-benefit analysis for all participants in the benchmark tests together with the specialist departments.”

From autumn 2014 the BMW Group invited Open Mind and five other CAD/CAM manufacturers to take part in benchmark tests, using a multi-phase selection procedure involving the software systems undergo intensive testing in tool making, series production, prototyping and what’s stated as an ‘internal BMW category’, CAM light.

On top of this there followed a technical evaluation based on presentations and programming tasks.

In early 2015 the shortlist moved on to milling tests, with users from the specialist departments at BMW M GmbH, Material testing, Tooling in Munich and Dingolfing being provided with training and began to use the system to programme components and tools.

HyperMill came out on top, but the more interesting note is on how you view the procurement process – whether you’re from a large-scale design and manufacturing background and you view the 18 month process as a rapid fire way of proving a solution, or you’re from a more nimble SME operation and your decision making process comes down to hours rather than months.

Feel free to let us know your thoughts below the line.