27,000 square feet of manufacturing magic: Autodesk’s Pier 9 facility is the workshop of your dreams

Sat on San Francisco’s bay, there are few facilities quite as desirable in our eyes as Autodesk’s Pier 9 – a 27,000 square foot playground of 3D printing, metal and wood shops.

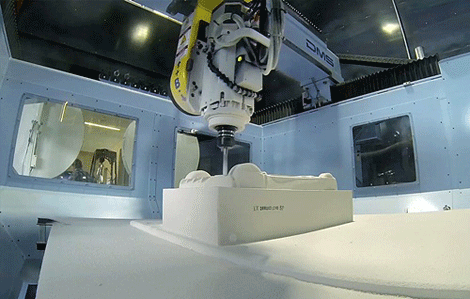

To power its mass of CNC equipment, Autodesk has added Delcam’s FeatureCAM to program all the CNC equipment at the facility, including a DMS five-axis router and a Mori Seiki mill-turn machine.

The Pier 9 facility opened in September 2013 to support the company’s vision of helping everyone to ‘imagine, design and create a better world’, while acting as an R&D department for engineers to have access to different tools and software for experimenting.

//www.youtube.com/embed/8I8hc0eJaDE?rel=0

“Pier 9 is a very interesting facility because it has traditional Autodesk software alongside an incredible workshop,” explained Gonzalo Martinez, director of strategic research at Autodesk. “It has a whole floor for additive manufacturing, plus we have a metal shop and a wood shop on the site. The best part of the whole concept is that it lets people experiment here. They have access to the tools that we provide – both the software and the hardware – to see what they can do.”

Pier 9 has a range of heavyweight kit, including this DMS five-axis router

Jeremy Malan, applications engineer at Delcam, was responsible for installing FeatureCAM at Pier 9. “It’s not every day that you can come out to a machine shop overlooking the bay, especially such a great facility,” he remembered.

“Pier 9 does have a lot of people that are learning machining for the first time so it’s really helpful that FeatureCAM is one of the easiest-to-learn software programs out there,” he added. “With FeatureCAM, even new users are able to identify very quickly the kind of feature that they are trying to make and how they are going to do that on the machine.”

Read our full Delcam FeatureCAM review here.