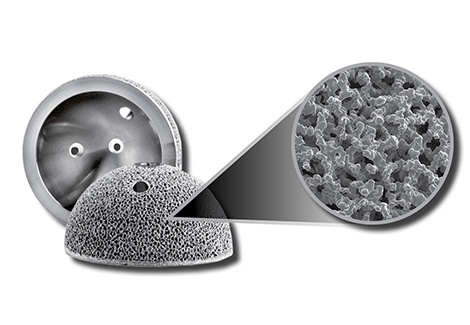

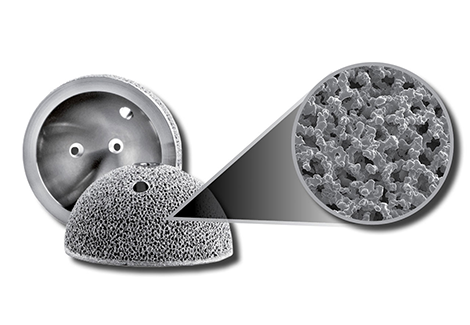

Acetabular cups with integrated trabecular structures for improved osseointegration, printed using Arcam’s EBM technology

Arcam has announced its medical application-focussed CoCr process for its Arcam Q10plus 3D printer, which will also be of interest to the aerospace industry.

CoCr is, together with titanium, the prime material for the orthopaedic industry, allowing the medical market to take full advantage of Arcam’s Electron Beam Melting (EBM) technology.

The Swedish company, recently the subject of acquisition by GE, states that the CoCr process provides parts with high resolution, production level productivity and ‘impeccable material properties’.

Arcam’s latest Q10plus 3D printer

The process is supported by an animal study by Gothenburg University, showing bone interaction with CoCr.

The newly released Arcam Q10plus 3D printer is the company’s latest iteration of its EBM technology, providing important features for facilitating efficient manufacturing.

The Q10plus replaces the Arcam Q10 system and features xQam an X-ray based detection system for automatic calibration and improved beam control.

The system runs its latest EBM Control 5.0 – a new software platform that increases beam control as well as new melt strategies to improve build speed and precision.