The list of kit installed at the Advanced Manufacturing Research Centre (AMRC) in Sheffield, UK, is already insanely mouth-watering but this has been added to with the addition of a new ‘world class’ composite forming facility.

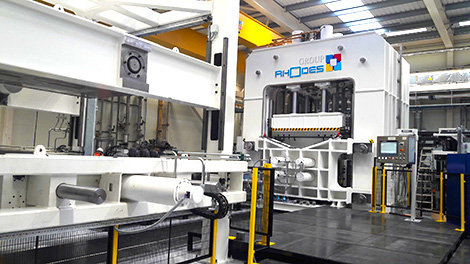

Custom built by Rhodes Interform, the brief was to design, develop and manufacture a composite press that could ‘do it all’ as it would be used as a facility to assist a wide range of UK companies to stay at the leading edge of composite development.

The delivered result comprises of a 10,000 kN hydraulic press with six-axis loading, high pressure RTM, twin die transfer tables, thermal fluid heating system and die splitter, capable of a wide range of composite forming including Open and Closed Moulding, Resin Transfer Moulding (RTM), Prepreg, Compression Moulding and Thermoplastics.

The unique project attracted funding from the Government’s Advanced Manufacturing Supply Chain Initiative (AMSCI), and has already been used as part of a successful joint venture to develop the future chassis of a UK based performance automotive company.

The machine will be available for use by companies looking to develop their composite capability through research and development in partnership with the AMRC.

Rhodes Interform, is a specialist in specialist in bespoke composite and metal forming machinery, including Superplastic Forming and Diffusion Bonding for both the aerospace and automotive industries and has previously won Queen’s Awards for both Innovation and International Trade.

Inside AMRC’s Factory 2050

Factory 2050 has been established to explore the intersection of Industry 4.0 and the re-configurable factory. We headed to Sheffield to learn more about AMRC’s latest facility – read the full article here