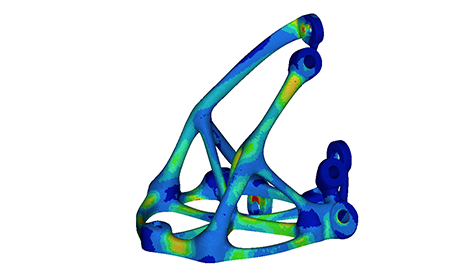

Example of topologically optimised component developed for 3D printing by Altair, RUAG and Morf3D

A triumvirate of leading players in additive manufacturing have joined to launch a practical additive manufacturing course which will cover the entire end to end process from design to certification.

The course, put together by simulation experts Altair, aerospace engineering company RUAG, and manufacturing services bureau Morf3D, covers a broad range of topics including basic design considerations, details of design, design validation, topology optimisation, build constraints, post-processing, destructive and non-destructive testing, virtual and physical validation and verification.

The course is taught at two levels by Dr. Melissa Orme, Morf3D, Dr. Robert Yancey, Altair and Mr. Michael Gschweiti, RUAG Space; experts that have successfully designed, built, and certified aerospace parts specifically for 3D printing.

Combined, this team has over 50 years of experience in aerospace applications, with additive manufacturing and 3D printing.

The intermediate and advanced courses take over four days to complete and cover a lecture and hands on exercises from design to build using direct metal laser sintering process.

The Intermediate Course is intended for people with a basic design and analysis background and the Advanced Course is for experienced engineers in design and analysis methods.

“We have seen a great interest from companies to learn how to best utilize additive manufacturing,” says Altair’s Dr. Yancey. “This course will provide participants a very practical view of 3D printing technology and how it can best be utilised.”