3D Systems has collaborated with Georg Fischer AG’s GF Machining Solutions to produce a joint industry solution, the DMP Factory 500, a scalable manufacturing system.

Designed to transform metal manufacturing through a simplified workflow to build metal parts up to 500 x 500 x 500mm, it aims to offer a lower total cost of operation while maintaining 24/7 production cycles.

A modular design enables continuous function of all metal 3D printing and powder management modules to maximise the uptime, throughput and operational value.

The solution is a customisable one – matching the number and type of modules required for their production workflow – with 3D Systems looking to enable customers to maximise their investment, while the integrated automation minimises manual processes to reduce total cost of operation.

In addition, the DMP Factory 500 system includes data connectivity with all major ERP systems to facilitate supply chain optimisation.

The DMP Factory 500’s five function-specific modules:

– Printer Module (PTM): designed to withstand the rigors of 24/7 production cycles enabling maximum printer uptime and output.

– Removable Print Module (RPM): sealed module for powder and part transport between printer, powder, and transport modules featuring a vacuum chamber to ensure the lowest O2 content enabling high quality 3D printed metal parts. Powder waste is eliminated, as the vacuum chamber guarantees consistent high material quality, sufficient to be re-used to depletion.

– Powder Management Module (PMM): efficiently de-powders parts on build platforms, automatically recycles unused powder materials, and prepares the RPM for the next build.

– Transport Module (TRM): enables efficient movement of the RPMs between printer and powder modules – reducing production time.

– Parking Module (PAM): provides interim storage of RPMs in an inert environment until ready for further progression in the workflow (e.g., stores a fully prepared RPM for its next print job while the PTM is finishing the previous print job).

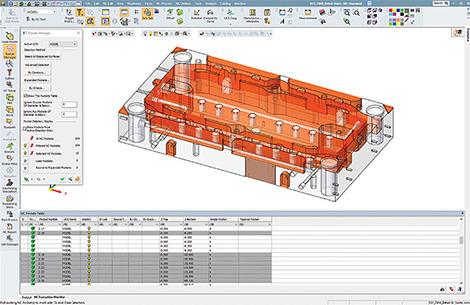

The additive manufacturing platform is integrated with GF Machining Solutions’ System 3R referencing and clamping system.

Zero point clamping enables optimal positioning of the build plate, facilitating a quick transition from the 3D printer to post-processing steps. This integrated feature reduces set-up times and provides enhanced flexibility by quickly transitioning the build plate from the additive process and sending it downstream for post-processing.

“The DMP Factory 500 is transforming and redefining how manufacturing gets done,” said 3D Systems president and CEO Vyomesh Joshi.

“Through our partnership with GF Machining Solutions, manufacturers will have a solution that combines additive and subtractive manufacturing and provides a simplified workflow.

“As manufacturing continues to advance, customers will start to expect high quality, large part production with significantly reduced total cost of operation, and with the DMP Factory 500, that’s exactly what they’ll get.”

By combining 3D Systems’ and GF Machining Solutions’ sales and support networks, the DMP Factory 500 customers will have a support network in more than than 50 countries. In addition to local technical support, customers will also have access to metals manufacturing applications experts at Customer Innovation Centers (CICs) in Leuven, Belgium; Denver, Colorado and Stabio, Switzerland.

3D Systems upgrades its software family for streamlined design to manufacture

3D Systems’ software suite has seen a raft of enhancements covering everything from digitisation through design and simulation, on to manufacture, inspection and additive manufacturing management.