Using 3D CAD the engineering teams at Clear Stream Environmental have improved efficiency by 25 per cent – making more water drinkable

Water is important, but we don’t have much of it: With the earth covered by around 71 per cent water, 2.5 per cent is drinkable, with only one per cent easily accessible, the rest frozen in glaciers and ice fields.

Droughts and pollution don’t help this matter, although water treatment technology is constantly developing to meet this essential human need.

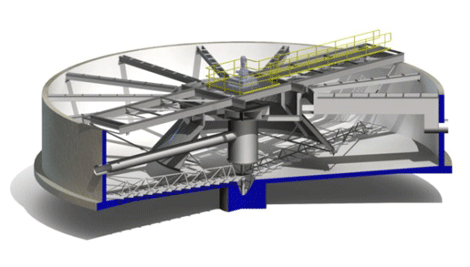

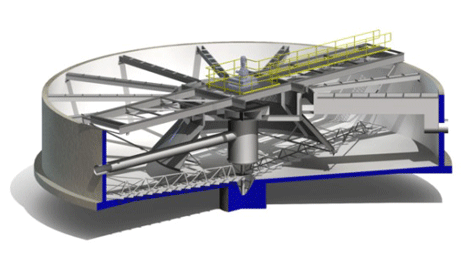

Clearstream Environmental has been challenging the usual development approaches as it aims to create future water treatment equipment, using its entire SolidWorks suite on the problem.

The equipment is heavy industrial design, requiring Clearsteam to use a number of SolidWorks products, including its Premium edition for modelling, while SolidWorks Simulation and Flow Simulation CFD analysis software helps to drive efficiency in power consumption.

This ability to solve engineering problems earlier in the design has boosted water/sludge separation efficiency by 25 per cent, with the time savings bringing systems to market four to eight weeks faster than Clearwater’s competitors.

“While many water treatment companies use 2D tools, we made the decision to use 3D design and simulation technology from the very beginning,” explains director of engineering Dustin Birch.

“By having detailed design and engineering analysis information at our disposal, we are able to consistently develop innovative, better-performing equipment, faster than our competitors.”