#3: Joe Graney, Engineering and Quality Director at Santa Cruz Bicycles has been talking about how the company moved from using AutoCAD to Pro/Engineer, to step up the quality of the products they build. Whereas other divisions of the company (Santa Cruz is a name that will be very familiar to anyone that’s ever been into Skating) are lifestyle brands, his team are serious about quality, professional products. As the company’s web-site About section says “All the marketing hype in the world won’t make a poorly designed bike handle well. Likewise, all the 3-D modeling software and metalworking technology in the world won’t amount to much unless the people directing it are serious about building truly great bicycles.”

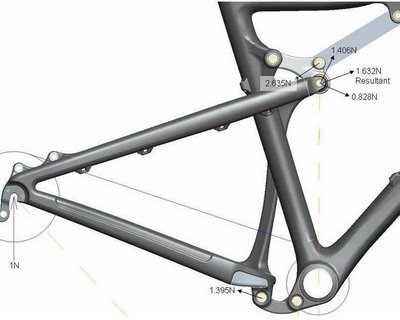

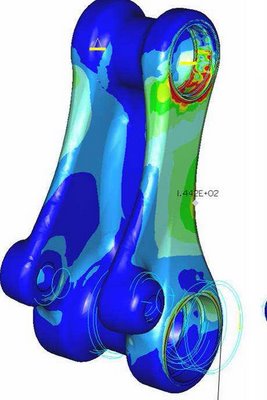

Santa Cruz was founded to build best in class full suspension bikes that are more efficient for riding uphill and faster downhill without sacrificing durability. According to Joe, the forces that act on bike, compared to a motorbike, are much more complex because of the cyclical nature of the loading on the frame and ride. Santa Cruz’ bikes now feature a four bar linkage (as opposed to a single linkage) that controls suspension actuation in a more efficient manner. Their manufacturing is split across the US, Taiwan and China, which as Joe says, “presents a whole new set of challenges.”

In terms of current design challenges, the primary requirement is for lightweight, high strength bicycles for very demanding consumers. He also talked about how suspension design is tied to mechanical design and aesthetic quality. Apparently, the team don’t employ industrial designers, but the engineers are perfectly aware of the requirements for the bikes to look distinctive). In terms of production challenges, the products have a very high tooling cost, long lead times for design changes. Perhaps the biggest challenge for the design team is simply time. The bikes have a short market life-cycle (36 months or less), a limited purchase window (for the race season) which all lead to a 14 month design cycle. The company’s toolkit includes Wildfire 4.0, Pro/Mechanica and Mechanism, Behavioral modeling , ISDX surfacing and Pro/Manufacturing.

All testing, design, simulation and NC programing is done with that set of tools and with the heavy requirement for simulation, the ability to pass native solid and surface data (something more common now that they’re transitioning to carbon fibre based frames), is key. Another interesting thing that came out was the benefit of using graphical output from simulation to communicate with non-english speaking team members overseas.

Also in terms of data sharing, according Joe, Pro/E has become the standard in the bike manufacturing community, so data sharing has standardised native Pro/E data, with many using the shrink wrap tools to hide any proprietary data.

They’ve managed to shorten product design time from 22 to 14 months.Suspension design iterations have increased from <10>100 per model. In terms of product benefits, the distinctive look of the bikes makes Santa Cruz unique in a very competitive market and warranty claims have decreased by 70%. The company is launching its first carbon fibre model later this month and its thought to be the lightest and strongest on the market.

In terms of moving into the future, Santa Cruz is looking to use PLM On Demand to help the group streamline communication between Asia based production staff, manufacturing partners and California based design teams and of course to ride bikes and win more races.

Want to see these things in action? Here’s a video: