PTC’s annual Media and Analyst event is a chance for the Pro/Engineer, Windchill, Arbortext, and CoCreate developer to explain what it has been up to, what its plans are and what its financial outlook is going forward. For the first time in a long while the Needham-based company actually had some product announcements to make and showed off lots of future technology, rather than discussing its finances at length. It’s strange how a global financial apocalypse does that to a company whose expected Q1 earnings are down so heavily on last year.

PTC made two key product-related announcements at the event. The first and big ticket item was the official launch of Windchill ProductPoint, first shown at the

PTC/User event in Long Beach last year. The second was a sneak peek into what’s coming in Pro/Engineer Wildfire 5, slated for release later this year (in time with its PTC/User event in June).

For ProductPoint PTC has taken Microsoft’s SharePoint and adapted it with its Windchill technology for the purposes of managing product development data

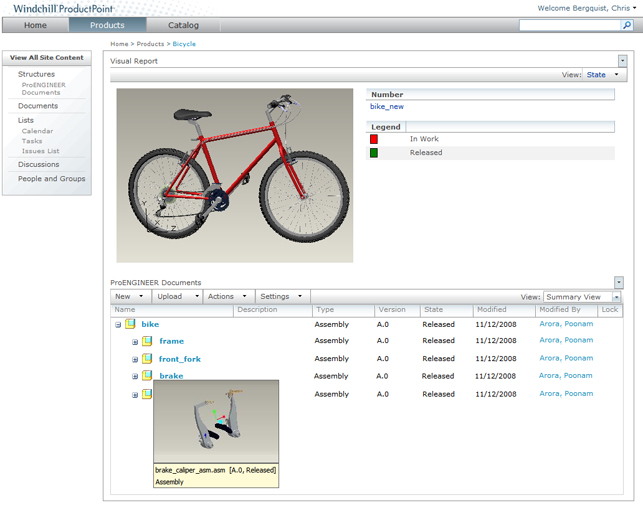

Windchill Productpoint

Windchill ProductPoint sees the core, underlying processes and workflows from Windchill, PTC’s PLM (Product Lifecycle Management) solution, applied to the Microsoft SharePoint platform. SharePoint is a general purpose document sharing and collaboration facility built into Windows Server and it’s very widely used by many kinds of organisations.

ProductPoint takes SharePoint and adapts it with PTC’s Windchill technology for the purposes of managing product development data. In the first instance, this means that it can handle management and control of the complex interactions between parts, assemblies and drawings and gives users the ability to “vault and share” that structured information. On top of this, it also adds search, visualisation and mark-up tools based on PTC’s ProductView technology.

Technical capabilities aside, PTC is using the term ‘Social Product Development’ to help market the product. Some might say that PTC is simply jumping on the ‘Social Media’ to impress investors or the wider concept of Social Computing as espoused by Microsoft, and to some extent this is true. But PTC is not alone in doing this. All vendors face the challenge of adapting their products to the changing online world, providing methods of interaction akin to MySpace and Facebook and other such technologies.

As PTC CEO Dick Harrison commented at the event, “There’s no such thing as standalone 3D CAD anymore,” and every vendor worth their salt, is looking to find new ways to integrate design and data management and add real value to the complex interaction between both data and the people authoring or influencing a product’s development.

While this will remain a big challenge for some time, for now it’s clear that there is a ground swell behind PTC’s management solutions. The company appears to have built a very capable solution, based on a data management platform that’s already installed in most organisations with 100 million licenses worldwide.

Lite add-ons

The other big news from the event was that PTC is doing something it should have done years ago. Despite the huge range of technology the company has in its arsenal – everything from analysis and simulation, through CAM and into digital mock-up – there was no real way to gain an easy footing into those areas without making a full commitment to acquire a lot of expensive modules. To remedy this PTC is going to introduce a ‘taster’ of these technologies with stripped back or ‘Lite’ functionality made available to every Pro/E user, and this is being done in three key areas.

CAE Lite: Using its established Pro/Mechanica technology, PTC is finally going to offer basic FEA (Finite Element Analysis) tools in Pro/Engineer, a strategy which was introduced by many of its competitors a while back.

Offering a simplified user interface to analysis, CAE Lite will guide users through the process of structural analysis of not only parts (as is done in SolidWorks and Inventor) but also assemblies. The system helps users set up loads and constraints and offers full results inspection and visualisation tools.

We got to hear more about technology and there was less ‘chest beating’ over financial perform-ance than previous years. There is an upside to this global economic crisis after all

CAM Lite: PTC has had Pro/NC for a long time and while there’s been some adoption, CAM is something that needs serious attention in terms of sales and development to make sure it gains serious traction. PTC’s NC related tools got a boost with the company’s acquisition of NC graphics last year and CAM Lite brings basic 2/5 axis milling tools, allowing the machining of basic prismatic parts, but in full 5 axis positioning if required.

Manikin Lite: Manikin Lite, the stripped down version of the human modelling tool PTC introduced last year, offers the ability to place and position human forms in 3D data environments, but there are limitations on how that form can be posed. Ergonomic analysis is also missing and there is no ability to save the designs with the manikin in place, which appears to be a huge barrier to adoption.

There’s huge potential for this type of tool to proliferate but for a technology which will not be familiar to the vast majority of users, surely users need to be able to save data so it can be evaluated properly in the real world.

Manikin Lite is available now, CAM Lite and CAE Lite will be available later this month, presumably through the PTC Customer portal. It’ll be offered to everyone within the Pro/E community, from the base level packages upwards.

Pro/Engineer Wildfire 5

Brian Shephard, Divisional Vice President of Product Management at PTC, gave a taster of what will be in the next release of Pro/Engineer. The big news is that PTC looks to have removed the need to regenerate a model when editing. A short video presentation showed a reasonably complex plastic part and ribs being ‘dragged and dropped’ with no need to rollback the model history or regenerate it.

There are obviously a number of questions surrounding this: how does it handle underlying parameters? What features can be edited in this manner? Only time will tell and we’ll certainly get the answers as soon as we can.

It’s also worth noting that this technology takes advantage of multi core hardware. While multi core processors are increasingly common, it’s the case that a lot of 3D CAD work doesn’t lend itself to multi-threading, so this is an interesting step.

The other interesting side to this is what happens when regeneration fails. Many will be more than familiar with the pain associated with seeing a history tree explode in your face meaning you’re staring down the barrel of a day’s worth of rework for a seemingly innocuous design change. Wildfire 5 looks like it’ll give you a much improved set of feedback about what’s happening, what’s causing the failure and then help the user work through it with better diagnostics.

Elsewhere on the modelling front, there’s a new Rib tool that’ll add draft and fillets (rounds), extend to walls automatically and has a lot more freedom in how the user defines the core geometry, so multiple loops and intersecting paths can be included. Curvature-continuous fillets/rounds and sketch Points can also be used for feature placement in a pattern.

Shephard didn’t talk about this, but the slides showed that an approximate offset feature is also being added. When shelling or offsetting geometry, the feature can often fail because of small faces, too tight fillets or complex surfaces, so being able to ‘fudge it’ makes a lot of sense, particularly if they’re not external or critical surfaces in terms of appearance or aesthetic quality. There’s also been some work done on the definition of welded forms, with new Weld features (such as spot, slot/plug, fillet and groove), as well as the ability to document those features.

Better mechanism models are also on their way with support coming for slot motors, dynamic gears, belts and 3D contact. Finally, Wildfire 5 will see new import tools for Inventor and SolidWorks data, plus better support for exchanging 3D notes and annotations and other non-geometric meta-data.

Unfortunately, alongside all this good stuff, there are still a few issues in the way PTC is developing its flagship products. The Wildfire releases have given Pro/Engineer a new lease of life and arguably stemmed some of the migration away from Pro/Engineer to competing 3D modelling products. However, the job isn’t complete and with Wildfire 5 looming, there are still some very noticeable inconsistencies. Take the detailing environment in Pro/Engineer, for example. This has been given a complete overhaul adopting the increasingly common Ribbon UI. It may look interesting and is high in functionality, but it is the only part of Pro/Engineer to get the Ribbon, while others use the Dashboard, and even the Menu Mapper. It’s puzzling why PTC still can’t deliver a consistent user interface.

In Conclusion

PTC is an intriguing outfit. It has a very interesting set of tools and Pro/Engineer is still incredibly strong, particularly in some sectors, such as Powertrain and Consumer Electronics/Product Design.

Alongside Pro/Engineer, there’s Windchill, which seems to be gaining a following amongst some very high-end customers, where you might expect Dassault with Enovia or Siemens Teamcenter to have a shoe in. The battle for providing the Volvo Trucks with a PLM system was a topic of conversation amongst the few European press in attendance. With Dassault already out of the race (odd considering Volvo Trucks is a Catia house), this leaves Siemens and PTC to battle it out. This is a perfect example of how well respected Windchill is in that type of account, but while it’s gaining ground at the high-end, Windchill has yet to see real traction in the mid-to-small market, the place where PTC is traditionally strong with its CAD offerings.

The release of ProductPoint, which adapts the basics of Windchill, and applies them to SharePoint, gives PTC a very interesting offering for a) Pro/Engineer users that haven’t adopted data management, b) those looking to add a more lightweight collaboration tool to full-blown Windchill and c) to users outside of that community with other systems. Plus, the chances are, users already have Sharepoint licenses installed and that gets them most of the way there.

In addition, PTC has other impressive tools in the bag. Arbortext, as can be seen from the Club Car example on page 35, can really help an organisation struggling with multi-language, multi-configuration product documentation.

Despite inconsistencies in its software development, Pro/Engineer, just like Windchill has always seemed to have a momentum of its own, while other newer products also appear to be gaining adoption in many places. However, as with most companies, the credit crunch is already taking its toll and Q1 2009 profit warnings have seen a sharp drop in its share price with many analysts predicting a takeover from a cash rich company. The good news was we got to hear more about technology and there was less ‘chest beating’ over financial performance than previous years. There is an upside to this global economic crisis after all.

www.ptc.com

Club Classic

Part of the Ingersoll Rand group, Club Car makes golf carts and the company’s Engineering Information and Systems Manager, Jeff Kennedy, came on stage to talk about how it is using Arbortext to cut the costs associated with documentation.

With over 100,000 vehicles a year and over 90 models on 12 platforms with electric, gasoline, and diesel powered variants, when you throw localisation into the mix, with a requirement for 17 language versions, you have a nightmare. Club Car worked with PTC to implement Arbortext alongside the Pro/Engineer seats already in use in the development department.

Kennedy was refreshingly frank in his presentation and discussed costs and how they stacked up against savings. The implementation cost was $326,000 for delivery of software and services and while the project was finished a few months later than planned, it came in $5,000 under budget.

Typically when people discuss technical publication and documentation tools like Arbortext, they stare with shock at the associated costs. However, the reality is that there is a huge potential for cost reduction with these systems. Club Car is the perfect example, saving $109,111 in the first year.

Furthermore, when considering the standardisation and easing of workload in a short period of time in a small team, then it’s clear that the return on that seemingly large investment isn’t too hard to justify.

Santa Cruz Bicycles

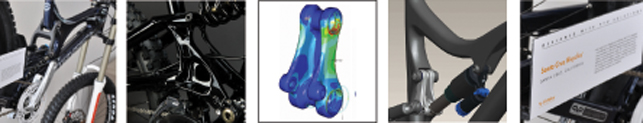

Joe Graney, Engineering and Quality Director at Santa Cruz Bicycles talked about how the company moved from using AutoCAD to Pro/Engineer, to step up the quality of the products it builds. Whereas other divisions are ‘lifestyle’ brands, his team is serious about quality, professional products. Santa Cruz was founded to build best in class full suspension bikes that are more efficient for riding uphill and faster downhill without sacrificing durability.

According to Graney, the forces that act on a bike, compared to a motorbike, are much more complex because of the cyclical nature of the loading on the frame and ride. Santa Cruz’s bikes now feature a four bar linkage (as opposed to a single linkage) that controls suspension actuation in a more efficient manner. The company’s manufacturing is split across the US, Taiwan and China, which as Graney said, “presents a whole new set of challenges.”

In terms of design challenges, the primary requirement is for lightweight, high strength bicycles for very demanding consumers. He also talked about how suspension design is tied to mechanical design and aesthetic quality. Apparently, the team doesn’t employ industrial designers, but the engineers are perfectly aware of the requirements for the bikes to look distinctive.

In terms of production challenges, the products have a very high tooling cost and long lead times for design changes. But perhaps the biggest challenge for the design team is simply time. The bikes have a short market life-cycle (36 months or less), plus a limited purchase window (for the race season) and this all leads to a 14 month design cycle.

The company’s toolkit includes Wildfire 4.0, Pro/Mechanica and Mechanism, Behavioral modelling, ISDX surfacing and Pro/Manufacturing. All testing, design, simulation and NC programming is done with that set of tools and with the heavy requirement for simulation, the ability to pass native solid and surface data (something more common now that they’re transitioning to carbon fibre based frames), is key. Another interesting thing that came out of Graney’s presentation was the benefit of using graphical output from simulation to communicate with non-English speaking team members overseas. Also in terms of data sharing, according Graney, Pro/E has become the standard in the bike manufacturing community, so data sharing has standardised on native Pro/E data, with many using the shrink wrap tools to hide any proprietary data.

With the help of all this technology Santa Cruz has managed to shorten product design time from 22 to 14 months, but also increase quality. For example, suspension design iterations have increased from 10 to 100 per model. In terms of product benefits, the distinctive look of the bikes makes Santa Cruz unique in a very competitive market and warranty claims have decreased by 70%. The company is launching its first carbon fibre model later this month and it’s thought to be the lightest and strongest on the market.

Al Dean travels to Boston for the annual PTC event