While I’m sworn to secrecy regarding the next release of Geomagic’s line of reverse engineering or, as they would have it, Digital Shape Sampling and Processing (DSSP), applications, there’s something that’s been talked about a little bit online and recently posted to the company’s labs web-site (labs.geomagic.com), that’s too good to resist a little yap about.

When you look at the use of reverse engineering within the context of 3D design, there are several workflows and processes that it supports. Whatever your end goal, the process of capturing a physical form digitally is used across a wide spectrum of the design and manufacturing world. There’s those looking to capture concept models/clays/styrofoam concepts and turn them into something more workable. there are those looking to capture organically generated shapes because that’s the only way they can be produced. Then looking into more production related applications, the use of revser engineering technologies is huge in many areas. Whether that’s the digitalisation of physical legacy parts for remanufacturing where either digital data doesn’t exist, or the ‘in-use’ part doesn’t match the source 3D data (something that’s huge in aerospace and turbomachinery). There’s also inspection and metrology applications that are gaining massive traction.

Whatever your use and purpose, it’s common that the scanned form is used as the basis for the construction of more accurate, cleaner surfaces. This is true of the automotive styling world as it is of the product design or medical market. you’ll start with a physical form, but your end requirement is a clean, smooth and fully featured surface or solid model. Now, the problem is that while you’ve traditionally been able to create surfaces and solids which can be passed to your workhorse design system, there’s very little in the way of intelligence. you can derive forms based on scan data, but editing that geometry, to effect design changes, takes complex edits and in many cases, complete rework.

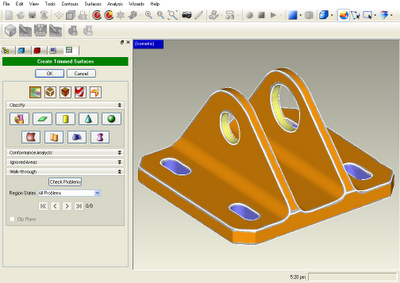

#1: Using Geomagic Studio to indentify ‘features’ and surface entities within your scanned data.

What Geomagic has done is to develop a series of connections that establish a link between its host application (Geomagic Studio) and either SolidWorks, Inventor or Pro/Engineer. You perform the standard scanning, registration and clean up processes (look out for a full review in DEVELOP3D in April for more information).

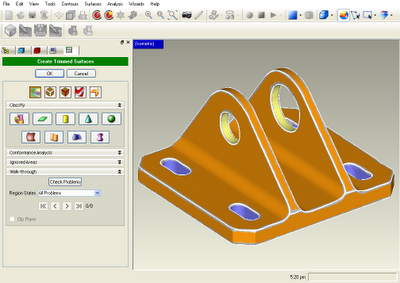

#2: Surface entities created using automatic and manual tools

But once done, you then use the built in tools (from the Geomagic Fashion module) to start to break down the model into precisely defined surfaces and solids. The system has, for some time, included a range of tools that allow you to create very clean surface/solid data using that underlying point cloud. This extends that by passing that same data to your workhorse CAD system. This is then used as the basis of reconstruction your models in your CAD system, using standard operations and features.

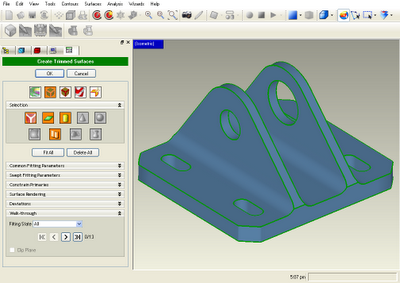

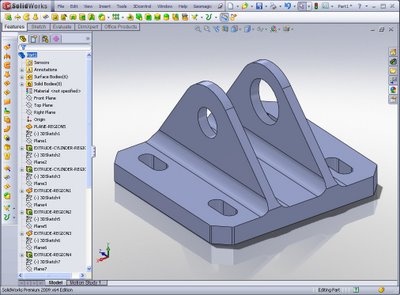

#3: Surfaces transferred to SolidWorks, with generating sketches in place and feature history constructed – ready for boolean and trimming operations.

The benefit this gives you is that you’ll end up with a quasi-parametric model which contains a great deal more intelligence (in terms of enabling design modification) than you’d traditionally get.

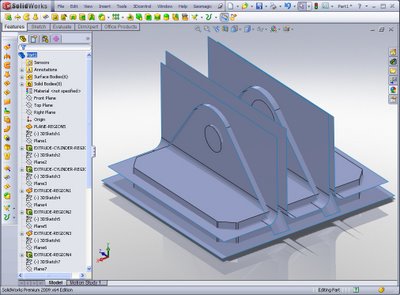

#4: Final SolidWorks model, clean, trimmed and intelligent.

Looks cool eh? it is. While Geomagic’s arch-nemesis, RapidForm has a similar tool in the form of RapidFormXOR/Redesign, Geomagic’s Parametric Exchange looks like a very elegant solution that lets Geomagic do what it does best (working with point cloud and polygon data) and leaves you to do the bulk of the surface and solid editing in systems best suited to the job. The images above show the system working with SolidWorks – now here’s a nice little video to show how it inter-operates with Pro/Engineer.