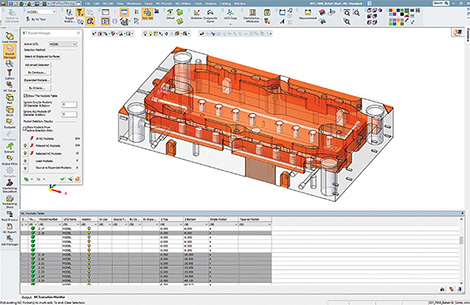

Cimatron 14 offers a new set of tools for those focussed on Mould and Die design

3D Systems’ software suite has seen a raft of enhancements covering everything from digitisation through design and simulation, on to manufacture, inspection and additive manufacturing management.

Automation to accelerate design and production processes is a big factor as 3D Systems looks to increase productivity levels for customers and reduce manufacturing Total Cost of Operation (TCO).

“We value feedback from our customers and continually seek out innovative approaches to their manufacturing challenges,” said Ilan Erez, senior software VP and GM at 3D Systems.

“The manufacturing experience and expertise which our team demonstrates allows us to develop unique solutions for our customers – helping to increase productivity, lower TCO and streamline workflows.”

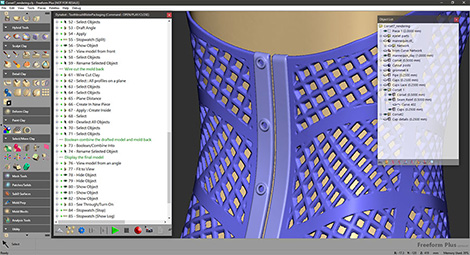

Geomagic Freeform 2019 has added automation for repetitive sculpt and modelling tasks

Key software updates, include:

Geomagic Design X 2019:

Geomagic Design X for reverse engineering combines feature-based CAD with 3D scan data processing, and maintains all the functionality necessary to digitise real physical shapes.

The latest version includes enhanced capabilities such as a streamlined direct scanning user experience, hole filling and automated file fixing, new sketching and blending tools as well as powerful surface fitting quality and continuity controls. Availability of Geomagic Design X is planned to be available Q4 2018.

Geomagic Freeform 2019:

Geomagic Freeform offers a comprehensive design and sculpting toolset to sculpt, detail and deform virtual clay models into any form through the incorporation of a haptic device.

The latest release of Geomagic Freeform – planned to be available this week – includes new functionality that simplifies the process of designing, automates repetitive modelling tasks to increase productivity, and deliver more consistent results.

Geomagic Freeform 2019 includes Dynabot which provides advanced record and playback macro capability to significantly speed repetitive customisation and production workflows – applying logic to recorded sequences, edit parameters, and insert user prompts and instructions.

GibbsCAM 13:

The latest release of 3D Systems’ GibbsCAM software provides a more streamlined user experience, additional milling and turning capabilities and an enhanced G-code editor, which improves the communication between software and CNC machining centres.

GibbsCAM 13 also offers elliptical turning, interpolated turning and eccentric turning – something 3D Systems claims is an industry first – allowing full functionality for Multi-Task Machining centers (MTM).

In another ‘industry first’, the software can offer auto-bar chamfering in a standalone software solution for programming Swiss type machines. GibbsCAM 13 is planned to be available Q4 2018.

Cimatron 14:

Cimatron is a single, integrated CAD/CAM solution designed specifically for tooling, with the latest release, available now, offering new and enhanced capabilities across CAD/CAM for tooling workflow.

Mould and die designers should benefit from an enhanced user interface resulting in faster, easier design. Through the use of barrel (segment) tools, NC programmers will be able to achieve more rapid machining.

Additional feature-based machining capabilities as well as a dedicated plate machining seat will enable programming of feature-rich plates more quickly and safely.

Finally, with the integration of ProgSim (Autoform) simulation, die makers should be able to reduce the number of tryouts required by validating the strip design before producing the die.

3DXpert 14:

An all-in-one, integrated software for the entire metal additive manufacturing workflow, 3DXpert encompasses preparation, simulation, optimisation, and post-processing operations.

3DXpert 14 puts a special focus on capabilities required to move from rapid prototyping to serial production. A new auto-balancing control enables high throughput production with best quality for 3D Systems’ multi-head new DMP Factory 500.

Enhanced integrated simulation facilitates faster design to manufacturing lead-time. Leveraging its history-based nature, 3DXpert now includes an Engineering Change Order (ECO) manager, enabling rapid design changes within the model versus needing to recreate it. Additionally, enhanced auto-orientation, new optimized lattice structures, and smart production labeling are included to help simplify the workflow, ensure successful part production, and reduce TCO. 3DXpert 14 is now available.

3D Connect Service:

3D Systems is jumping into the Industrial Internet of Things (IIoT) for manufacturing, with its 3D Connect Service cloud-based solution that enables proactive and preventative printer support in the production environment.

Real-time remote diagnosis, automatic support case creation, and usage-based preventative maintenance scheduling are all offered in 3D Connect Service – which should help maximise productivity and speed time to resolution, and importantly – increase printer uptime.

3D Connect Service is planned to be available in Q4 2018 for several plastic and metal printers.