Amphyon brings automated support generation to Additive Works’ Laser Beam Melting 3D printing process

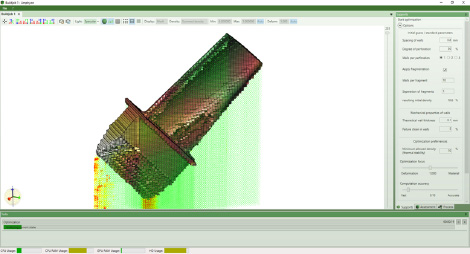

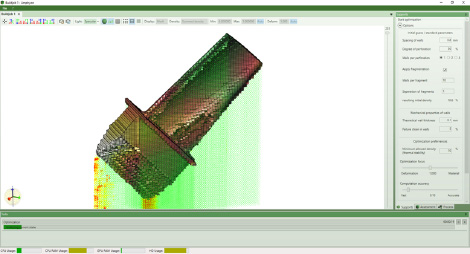

Amphyon, Additive Works’ simulation-driven process software for powder bed-based, laser beam melting additive manufacturing processes, has been substantially upgraded to include automated supports.

Already enabling automatic optimisation of part orientation as well as a build-up process simulation and the adaption of process data in order to achieve higher part quality and process stability, now the tool includes an automated process for first-time-right support generation for Laser Beam Melting.

Essential for a high-quality print, if supports are not sufficient in strength or designed to withstand heat conduction, the quality or the shape of the part is likely to significantly deviate from the desired result.

With the new Amphyon module, this process can be improved by using the tool’s new automated workflow, with Additive Works co-founder and CEO Dr Nils Keller explaining it has been designed to replace the “experiment-driven development of build-up strategies” in laser beam melting.

“With the new module we are expanding the capabilities of Amphyon, helping our customers to become even more efficient,” commented Keller, who helped found the company with three other interdisciplinary professionals in late 2015 as a spin-off company out of the University of Bremen.