https://giphy.com/embed/xT0xeqHTBfTEmrfsQ0

3D Systems continues to push its plans for extended manufacturing with additive technologies, launching a new metals 3D printer ready for the automated production line.

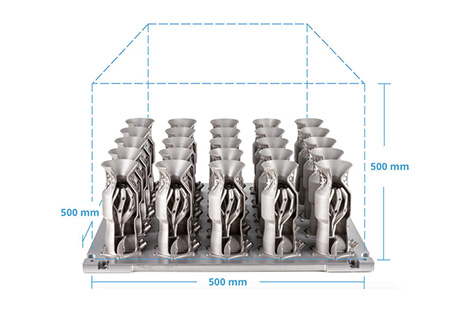

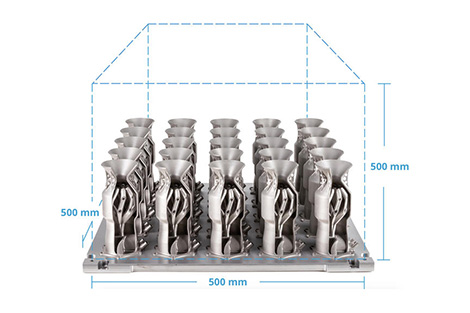

Based on the company’s existing SLS metals technology, the DMP 8500 is a scalable, automated and fully integrated – from powder in to part out – metal additive manufacturing solution, with a build chamber 500 x 500 x 500 mm, the system is engineered to open up new applications for users.

The modular design, combined with practicalities for production line use, such as rear access and ability to be placed side-by-side with other 3D printers, while sealed, removable print units manage powder and part transport between printer, powder, and transport modules for a continuous production workflow.

3D Systems says the print bed has the ability to ‘print the largest diameter parts’ thanks to its 500mm3 build area

Powder management modules de-powder parts on build platforms and automatically recycle unused powder, before preparing the materials and print module for the next build.

As the build area suggests, it’s a huge piece of equipment should the images of little robots whizzing around stations confuse you, something that Vyomesh Joshi, president and chief executive officer, 3D Systems, says is coming as direct customer requests.

“The industry is at a point where companies are looking to scale up their metal 3D printing production, bridge the chasm, and move onto the factory floor,” he said.

“The DMP 8500 Factory Solution was developed by experts with deep knowledge and experience in factory solutions and takes metal printing technology to a new level of economic efficiency for our customers.”

Meanwhile the company is continuing its development of the Figure 4 solution following its unveiling in March. The modular, scalable platform can add units to it as manufacturing capacity grows.

According to the company, the 3D printer can produce up to 15 times more throughput versus competitive offerings, and up to 20 per cent lower part cost than current manufacturing processes.

The Figure 4 will be available from Q1 2018, with units will start at around $25,000 and over $1 million for highly-customised, in-line production systems.

Additionally, 3D Systems launched a whole host of new materials, taking the number of its in-house produced consumables to roughly 70 – quite a stable.

New production SLS materials include DuraForm FR1200 fire retardant nylon, DuraForm EX BLK nylon 11 and DuraForm AF+ aluminum-filled nylon.

The company also introduced new rigid and engineering grade materials for its MultiJet Printing (MJP) platform that it claims are more durable and produce lower cost functional prototypes than competing systems.

These new engineering materials offer tough, ABS-like and durable, polypropylene-like properties, with mid-low modulus, high elongation and high impact strength.

A new rigid gray material offers high contrast that’s “exceptional for viewing fine details”. In addition, several of its rigid materials are certified USP Class VI and pass ISO 10993 for use in medical device applications.