Under the Airbus’ Test and Evaluation program, Sigma Labs has announced it will provide the aerospace giant with its PrintRite3D In-Process Quality Assurance (IPQA) system and services for metals additive manufacturing.

PrintRite3D provides process knowledge and understanding about melt pool dynamics that can lead to improved process consistency and a broader scope of applications for additive manufacturing.

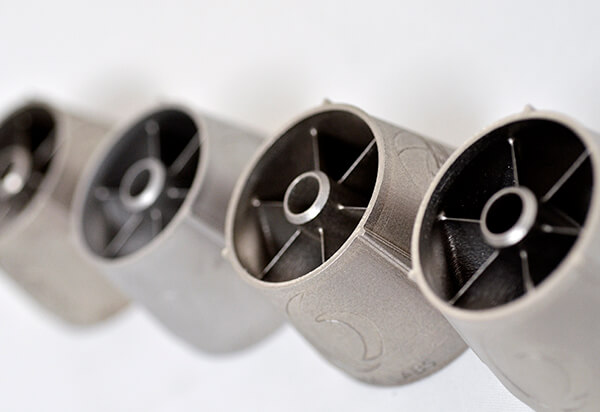

Consisting of hardware, software, training, engineering and metallurgical consulting and support services, the goal is to demonstrate its ability to monitor and characterise material, machine process and production consistency and repeatability of additive manufacturing operations.

As the application and growth of additive manufacturing in the aircraft industry continues to advance, the required process qualification is critical to increasing and assuring quality, reducing waste, and raising quality yields.

Sigma Labs chairman and CEO John Rice, said: “We are honoured and indeed feel very privileged to have our In-Process-Quality-Assurance tools as well as engineering staff engaged with Airbus,” adding that the AM industry appears to be accelerating in its sophisticated quality requirements including accurate and economic third-party quality assurance. “We at Sigma have committed ourselves to meet that need.”