After hitching a ride on SpaceX technology, Launcher’s plan is to place in orbit private cube satellites. Stephen Holmes hears how in-house additive manufacturing helps Launcher keep tab on the costs of being a cosmic courier

With the small satellite revolution ready for take off, Launcher plans to become a big name in the business of precisely placed satellites.

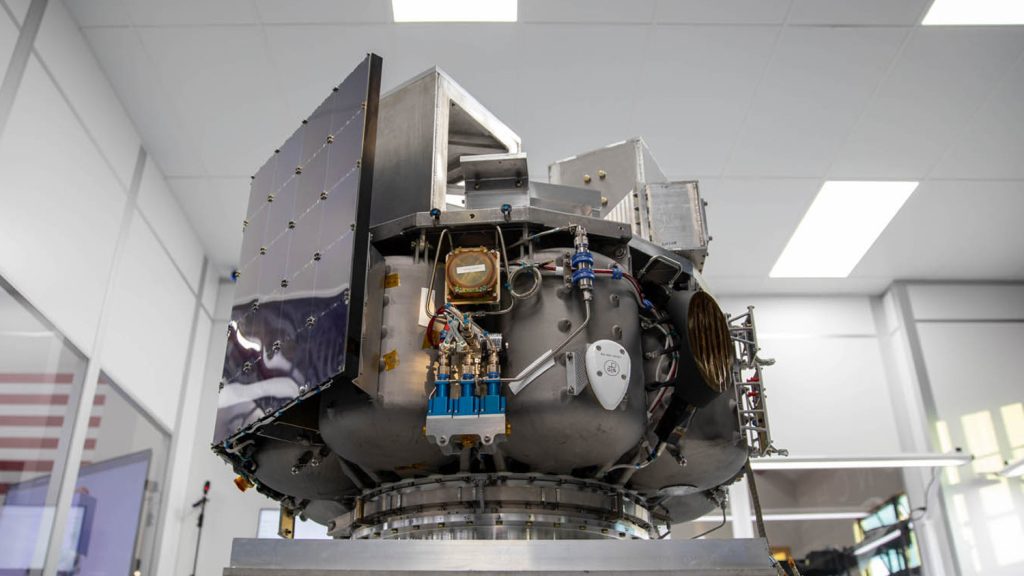

After first hitching a ride on the SpaceX SmallSat Rideshare Program, Launcher’s Orbiter satellite transfer vehicle will then independently venture on into space, before launching satellites of its own.

It is estimated that, this way, a 400kg payload of cubesats and small satellites can be deployed per mission, allowing them to be precisely placed into whatever orbit their owners desire.

Beginning in 2024, the company will offer its own launch service—Launcher Light. This is a liquid-fuelled rocket measuring 15.2m long and 1.1m in diameter, and capable of carrying 150 kg and 105 kg payloads into lowearth orbit and sun-synchronous orbit respectively.

Development timelines for Launcher are short, to say the least. Orbiter’s design began as soon as SpaceX announced in early 2020 that it would begin selling payload space on its Falcon 9 rocket.

Based in Hawthorne, California, the Launcher team realised it could make its satellite deployment system compatible and decided to fast-track the project.

None of this would have been possible without additively manufactured metal components, according to Launcher head of manufacturing Tim Berry. The most challenging of these are produced on a Velo3D Sapphire 3D printing system.

Before joining Launcher, Berry worked at SpaceX for close to a decade. During this time, he led the Falcon 9’s second-stage integration team. That work was followed by leadership roles on the Dragon’s crew and cargo capsules, before transitioning to head of additive manufacturing.

Today, he oversees Launcher’s 24,000 square foot factory floor and its team of machinists, welders and technicians, as well as the company’s small fleet of metal 3D printers, chief among them being the Sapphire systems.

Launcher // Space-proven turbopump

To begin the design process, Launcher licensed the drawing for a space-proven turbopump, and then set about improving its design using 3D printing.

One notable part is the engine’s shrouded impeller, a critical and complex Inconel part that spins at 30,000 rpm, which must withstand more than 300 bar of outlet pressure, and is filled with notoriously hard-to-print, zero-degree angle surfaces.

“The team at Velo3D took the challenge and we ended up with a finished part that exceeded all of our performance objectives,” says Berry. “That was the beginning of our relationship.”

Launcher subcontracted most of its parts to a network of contract manufacturers. And while those companies did a good job, CEO Max Haot realised that the company would never achieve his goal of fast, flexible and above all cost-competitive manufacturing unless Launcher became as vertically integrated as possible.

“As a modern space and rocket company, we have several important goals,” says Haot. “The first and most obvious one is for Orbiter to deliver the lowest cost in the industry for the highest propulsive capability. But to achieve that, it’s critical to have in-house design and manufacturing capabilities.

“Every time you buy a separation ring, propulsion system or support structure from a third party, your costs and lead time easily rise by a factor of 10. So instead of the week or so it takes us to design an engine, print, and test it, we would spend maybe two or three months with an outside provider. It’s prohibitive.”

Berry interjects and points to the fuel tanks as a typical example. “Shop around for a space-graded tank able to withstand 3,000 psi of pressure and you’ll probably hear lead times of 8 months to two years, especially if they’re custom,” he said. “That’s not an option in our environment, so as with many of our components, we took the approach of designing based on our available tools.”

As it happens, the Orbiter’s 22-litre tanks exactly match the Sapphire’s build volume. Launcher began by printing the parts out of Inconel, and although they performed well, Berry and the team started looking for ways to optimise the design. Moving to lighter-weight titanium was the obvious choice.

“That’s what brought us to our second machine from Velo3D,” he explained. “It can print the exact same tank but with less weight and higher pressure capabilities. We already thinned the walls a bit compared to the original design, but once we have the first few launches under our belt, we’ll probably reduce them even further as we continue to push the envelope.”

That’s one of the biggest advantages of having inhouse printing capabilities, he notes, as Launcher can continually push for more aggressive designs and higher performance without losing a lot of time or spending a lot of money.

As such, the company is 3D printing a range of components on its Sapphire systems, among them brackets and other secondary structures, combustion chambers and injectors.

“We don’t have to completely change our design to make it work with the Velo3D printer,” said Berry. “And in most cases, we can use whatever geometry we had planned. There’s no need to make a bunch of compromises like there so often is with metal AM.”

The start-up hopes to soon place payloads into customised orbits for a little more than $8,000 per kilogram. “These rideshares occur every three months, but if SpaceX’s timing or trajectory does not meet our customers’ requirements, we’ll also have a premium launch service through our Launcher Light offering,” said Haot. “Either way, these services come at a price tag that’s unprecedented in the space industry.”