Riven is introducing a new re-scaling tool for 3D printing, which aims to makes it easier to print parts more accurately.

Riven’s software automatically computes re-scaling factors as compared to the original CAD, which should make all 3D printing processes, from FDM through metal 3D printing, more accurate with quick 3D re-scaling.

Unlike checking limited dimensions with calipers or a CMM, Riven uses a full part capture to compute an optimal solution based on the entire part shape to produce a more accurate result.

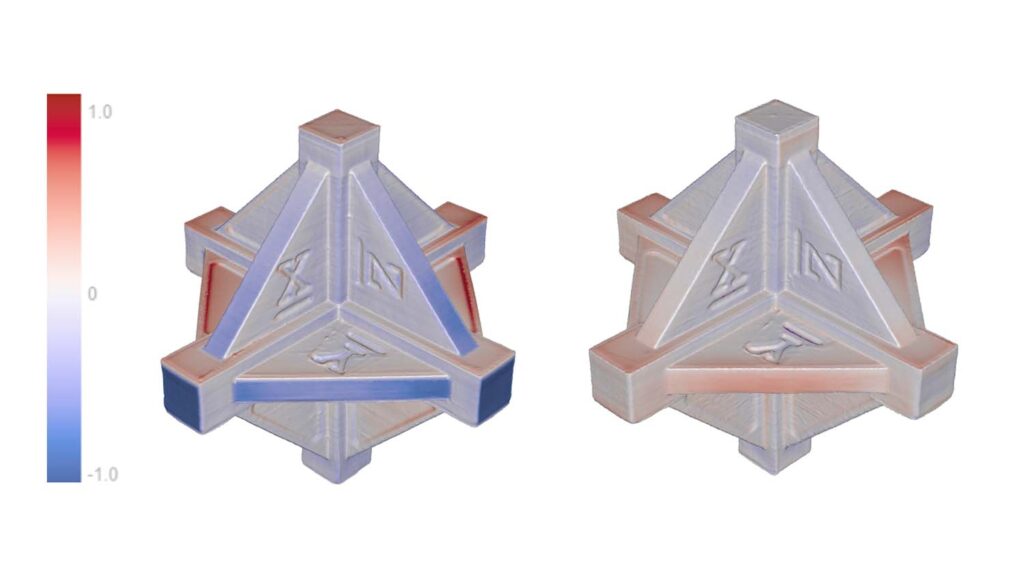

The company suggests that its solution takes only minutes for Riven’s to quick re-scale and create results with clear indications of the location and degree of variance from the intended design.

After applying the re-scaling factors, the CAD-compare result for the second printed part shows that it is more accurate, with deviations reduced significantly in critical areas.

Once Riven’s re-scaling tool for 3D Printing has checked a test part, new parts can be quickly adjusted using the established re-scaling factors.

“Fast 3D re-scaling data can save hours, iterations and costs and produce significantly more accurate parts,” said a Riven spokesperson. “With only a few minutes for a quick scan and automatic CAD-compare, Riven keeps your projects running smoothly even when you change materials, settings or print in a different location in the print volume.

“Riven’s re-scaling tool can even be used to calibrate the entire build volume for binder-jet and other professional machines.”

Riven says its software fundamentally simplifies 3D reality data acquisition, analysis, and collaboration to accelerate new product introduction, improve product integrity and drive production automation.