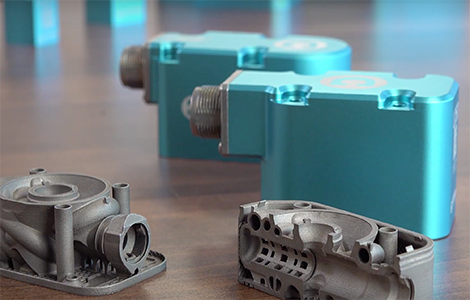

After spending years on testing different prototypes and designs Domin Fluid Power has launched a new range of fluid servo valves developed with metals 3D printing technology at its core.

An example product is 25 per cent of the original size and 25 per cent more powerful, while being produced at a third of the cost, with much of the benefits arising through collaboration with additive manufacturing experts Renishaw.

“We’ve worked with Domin throughout the whole process, from investigating material properties, to exploring the advantages of using the latest technologies, such as the RenAM 500Q, in production,” explained Renishaw AM lead technical consultant Martin McMahon.

Domin collaborated with Renishaw to develop an entire technology suite for the fluid power sector having visited Renishaws Solutions Centre to see how AM technology could improve productivity in high value, small volume production, including its compact RenAM 500Q metals 3D printer which features four 500 W lasers to speed up the printing process.

“Additive manufacturing is a key technology for Domin,” continued McMahon. “It gives the company the ability to build complex parts, free of tooling and with minimal operations and assembly. Trying to integrate such complex functionality into such a small design would not be possible using conventional manufacturing techniques.”