Meltio has launched its Engine Blue technology, which it says opens up its wire-fed Directed Energy Deposition (DED) 3D printing capabilities to new materials with greater speed and simpler operation.

Its blue lasers melt the metal material – stainless steel, titanium, copper, aluminium, and nickel among others – making it possible to print metal parts with high reliability and optimal density, suitable for a wide range of industrial applications.

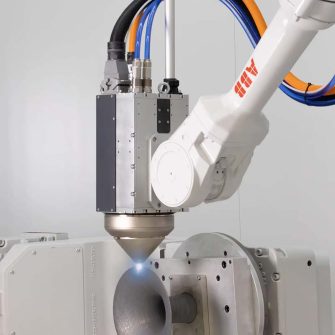

The new Engine Blue features a 1.4 kW blue laser head as part of its fibre optic-free system that is more compact and lightweight, making it compatible with a wider range of vertical machining centres and robotic arms.

Without fibre optics or collimators, Meltio says that the deposition head will also make the installation and maintenance process much simpler, while still maintaining an integrated camera and quick connectors.

By eliminating the need for constant laser alignment and adding an improved wire feeding system, the new solution should allow for more continuous and uninterrupted operation.

In addition, Meltio says that the use of Blue Lasers reduces energy consumption by 30 per cent and offers a deposition rate up to 3.5 times higher than the previous version.

“The development of the new Meltio Engine Blue has been a painstaking process of more than two years, in which our engineering team has worked collaboratively with our partners and integrators to identify and overcome the challenges faced with the V3,” said Meltio product manager Alejandro Nieto.

“Among the most important industry demands were the need to reduce maintenance time, increase reliability, and improve deposition rate. The elimination of components such as fibre optics and collimators has simplified the system, while the blue laser head and dual power supply system allow continuous and flexible operation, adapting to different materials and applications.”

The system is now available as an integration kit, as a natural evolution of its predecessor, the Meltio Engine which used infrared lasers. The Meltio Engine Blue simplifies manufactured metal parts and accelerates printing capability and adoption speed for vertical machining centres and industrial robot arms using its wire-laser metal DED technology in factories and machine shops.