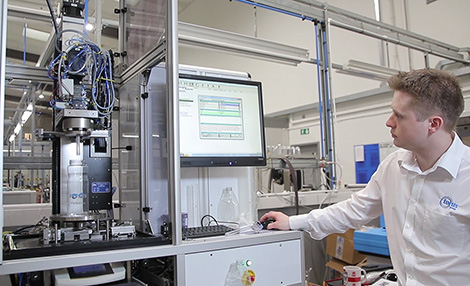

Having began its prototyping with a Makerbot, the R&D team at UK-based metrology experts Torus Group, has noticed the benefits of its latest 3D printer upgrade.

The Torus Group, which provides automated part measurement solutions for internationally renowned names like Coca-Cola, Rolls-Royce and GlaxoSmithKline, had already acquired an Stratasys Objet30 Pro.

Having found the possibilities of multiple materials 3D printing too tempting, it invested in a Stratasys Objet260 Connex3 from SYS Systems, a UK platinum partner for Stratasys.

The biggest benefit has been the ability to build seals and other parts from Stratasys rubber-like material families Tango and Agilus.

“Our top-load gauge essentially fills up a bottle with water and puts a load on the top of it,” explains Torus R&D engineer Laurence Newman.

“It has a lot of water inlets and outlets and we managed to print those channels through the part, which was something that was really hard to do with traditional manufacturing methods.

“We’ve redesigned the whole part of that gauge based on the fact we can use the Objet260 Connex3 to its capabilities and we’re hoping to use the printer across all of the gauges that we make.”