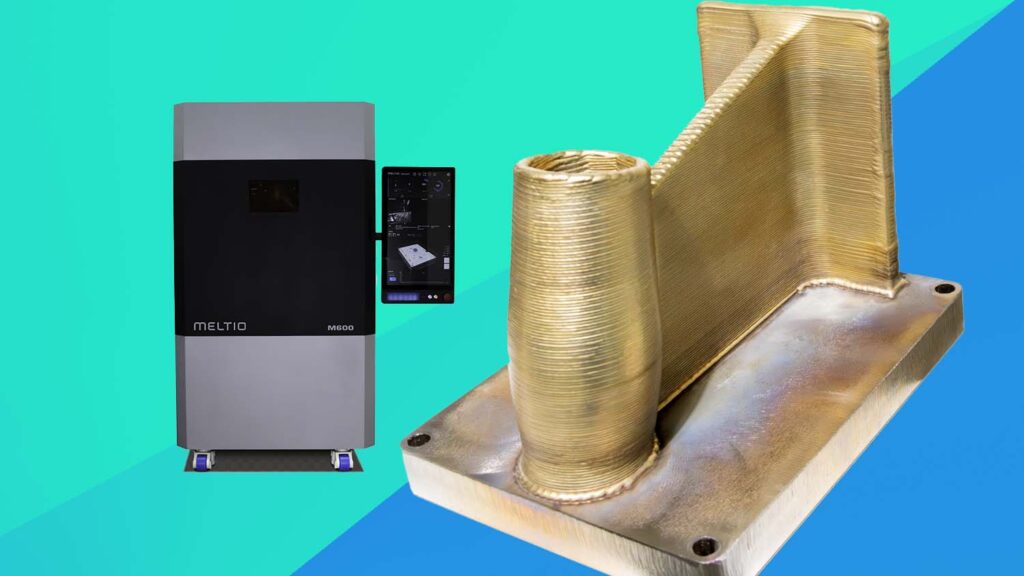

The new M600 wire-laser system sees Meltio bring its DED 3D printing technology to the shop floor by utilising Blue Laser technology to deposit welding wire as its feedstock.

A 300 x 400 x 600mm fully inert workspace equipped with smart sensors should allow for large parts to be built using demanding materials, including titanium, copper and aluminium alloys, as well as stainless steels, tool steels, nickel, invar, and Inconel.

Designed specifically for machine shops and production environments, the Meltio M600 is capable of 3D printing entire metal parts but also adding features to existing components and repairing damaged surfaces.

This range of capabilities is facilitated by the built-in 3-axis touch probe and support for various workholding solutions, including zero-point clamping.

Meltio R&D Director Lukas Hoppe, explained that the design brief for the new Meltio M600 was to imagine what the perfect 3D printer for the machine shop would look like.

“The vast majority of metal 3D printed parts require post-processing which is carried out in the machine shop and since our ambition is to push the large-scale adoption of metal additive manufacturing we have a very clear vision that the modern machine shop is the ideal point of entry,” said Hoppe.

“We still see metal AM mostly applied to very high-value applications, and this is where the Meltio M600 comes in as it improves on the state-of-the-art in a few very significant ways. Our newly developed Blue Laser deposition head increases printing speed while reducing energy consumption thanks to the increased absorption of the short wavelength light compared to most industrial lasers which emit near-infrared light.”

Hoppe explains that the advantage is multiplied for reflective materials such as copper and aluminium alloys where near-infrared lasers lead to unsatisfactory results. Combining this with the fully inert workspace, the Meltio M600 can process a large range of materials efficiently while producing parts with exceptional properties.

Meltio has developed the system to operate autonomously, meaning that operator interaction is minimal. Common touch points such as manual laser alignment have been removed for increased reliability and programming is sped up thanks to Meltio Horizon, a dedicated slicer for the Meltio M600.

Hoppe continues: “The Meltio M600 for us was really the next logical step on our continuous journey towards mass adoption of Wire-Laser DED, the process all Meltio systems are based on… We developed every single part of the machine from scratch to take the technology to the next level, based on the learnings of having manufactured and installed over 300 Laser DED machines.”