HP has launched a new ‘high reusability’ Polypropylene (PP) 3D printing material, developed through its partnership with BASF – creating a versatile, durable, and chemically resistant material for HP’s Jet Fusion 5200 3D printing systems.

The new HP Polypropylene material should give users the same properties as ‘commonly used PPs in injection molding’, which has a wide range of uses across all industry verticals, and up to 100% reusability of surplus powder.

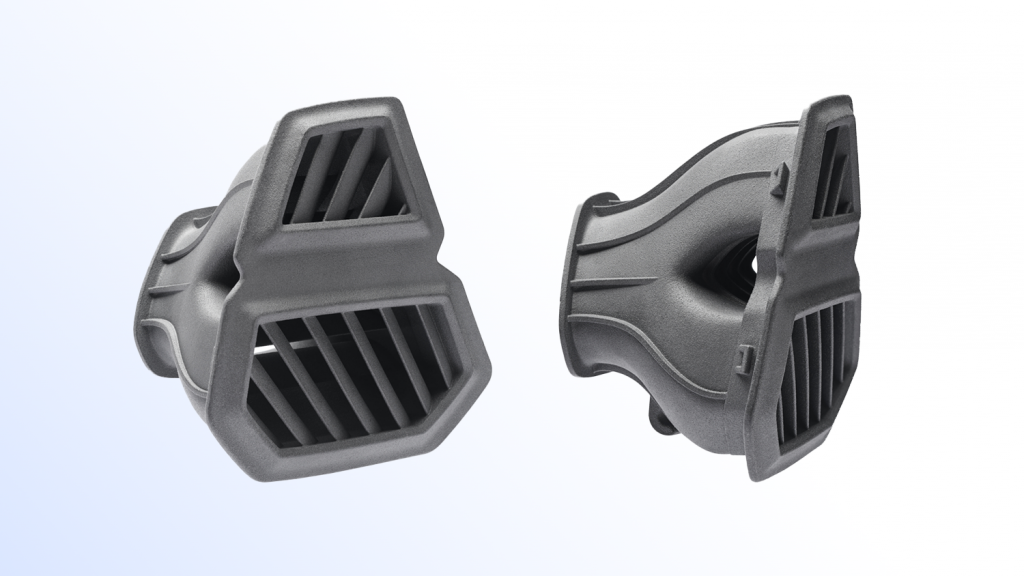

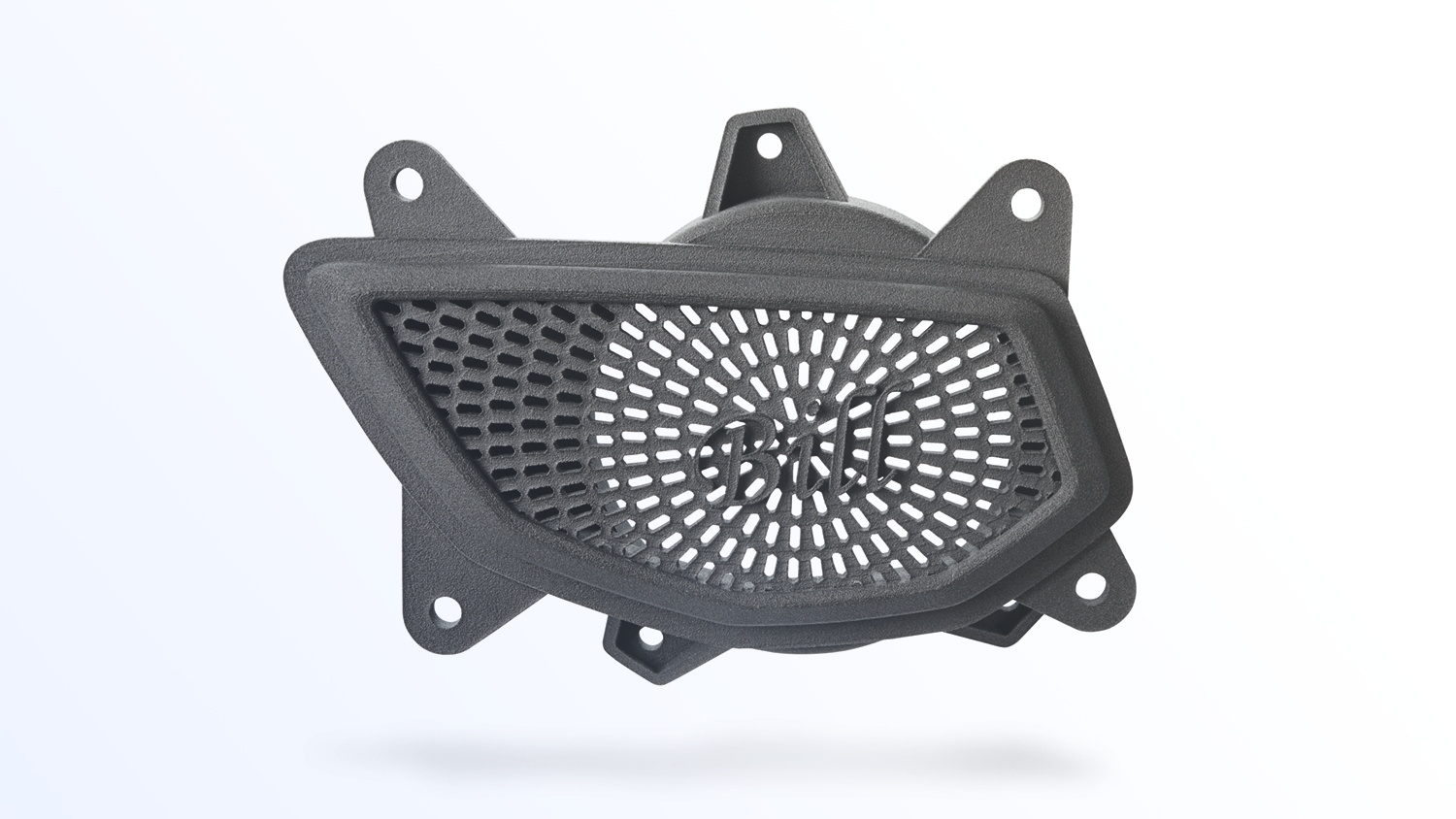

As an example of its versatility, automakers should be able to use the same HP Polypropylene material for prototyping and production of final parts found in vehicles’ interior, exterior, and under-the-hood.

The launch of the new material in partnership with BASF follows that of the strategic alliance’s recent introduction of the innovative Ultrasint TPU01 thermoplastic polyurethane.

“With the new PP and , the two industry leaders are working together to accelerate the design and mass production of 3D printed parts, enabling customers to go to market faster, more cost-effectively, and more sustainably than ever before,” said a HP spokesperson.

Additionally, HP has announced further PP applications with partners, parts providers, and customers including Extol, GKN Powder Metallurgy/Forecast 3D, Henkel, Prototal, and a new partnership with Oechsler.

To help its customers accelerate towards digital manufacturing, HP unveiled new and expanded 3D Professional Services offerings.

These capabilities include design optimisation for breakthrough applications, manufacturing process streamlining to enable mass customisation and scale production, and applications identification and discovery services.

The new strategic alliance with Oechsler AG received quite a fanfare from HP, though should not come as much of a surprise.

Oeschler is a leading global engineering solution provider and already uses its fleet of HP’s Jet Fusion 5200 3D Series printers and an extensive materials portfolio to realise applications in automotive, consumer electronics and commercial appliances.

The additional news at the press conference involved Fast Radius, a leading manufacturing technology company, which has qualified as the latest member of the HP Digital Manufacturing Network, HP’s global community of HP production partners.

“As we navigate this new landscape, we continue to execute on our strategy and push innovative new 3D printing materials, solutions, and partnerships forward to help our customers re-open manufacturing and deliver disruptive innovation for the world’s industries,” said Ramon Pastor, interim president of HP 3D Printing and Digital Manufacturing.