Google ATAP (Advanced Technology and Projects) is working to create innovative products across a wide range of applications, exploring how technology can be more accessible, helpful, and ultimately – human.

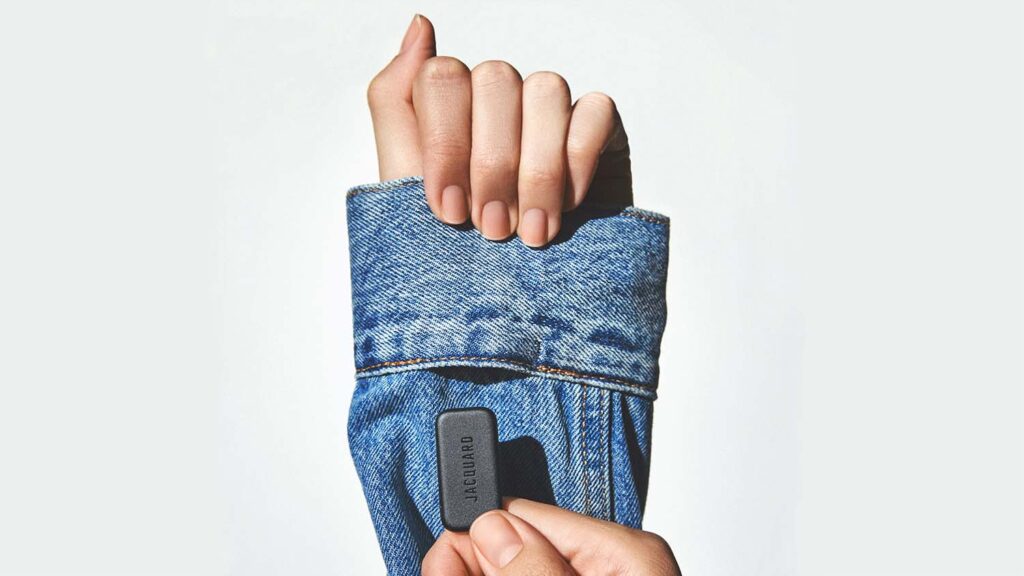

One project recently released to the public is the Jacquard Tag, a small wearable that looks to bring the digital into everyday experiences, without disrupting the user’s lifestyle.

The app partners with a physical tag that can be incorporated into a number of soft goods – from sports shoes to Levis jackets – allowing for interactive digital experiences without needing to physically hold a device.

Incorporated the tag into the sleeve of a denim jacket, Jaquard enables a set of motions, like swiping or tapping the sleeve, to perform actions such as pausing music, taking a photo, or answering a phone call.

“Our team is really looking for solutions. We’re always searching and exploring new technologies, but in the end the most important thing is application-driven innovation,” explains Bryan Allen, technical program manager and ATAP Lab lead.

The team specialises in 3D printing and advanced fabrication, so it works with many different additive manufacturing technologies, including PolyJet technology from Stratasys.

Merging a hard goods and soft goods product pipeline gracefully proved one of the key hurdles – melding traditional and digital manufacturing.

ATAP Lab lent on the versatility of Stratasys PolyJet technology to allow designers to jump in at any stage of the design process and create the prototypes they needed, from single-colour concept models to functional, multi-material, full colour prototypes that add to the realism.

“We’re talking about things that didn’t exist before,” says Allen. The team needs to be able to closely replicate the multi-material assembly of the final product, and that process needs to happen fast. Typically, getting a multi-material prototype would take weeks, but with PolyJet, the Google ATAP team can hit print at the end of the day and have a high-fidelity model in engineers’ hands the next morning.

Stratasys has made that process even easier with the recent announcement of support for KeyShot 10 rendering software and the 3MF file format. By saving designs to 3MF, KeyShot produces files ready for printing, with accurate colors and displacement maps to three-dimensionally simulate textures.

“A lot of designers are using KeyShot. The closer the end part coming off the printer looks to the KeyShot rendering and the easier it is to go from the designer’s vision to the final print, the better,” Allen says.

The result is that designers get more questions answered faster. In other words, says Allen, you’re “de-risking” the process. “You’re buying design time to explore and optimise your solutions and get critical needs done so you can move into the next stages.”

Having that extra time is critical for groups like Google ATAP, which is focused on creating truly novel products that enhance tech experiences.

The team looks to develop products that can be integrated in multiple areas, with the versatility to help users in a range of different environments and experiences. That, explains Allen, is why Jacquard is so exciting.

So far, in addition to the denim jacket, the ATAP team has used the Jacquard platform to introduce a wearable gaming athletic shoe and a smart backpack, with more to come.

Meanwhile, the team continues to use 3D printing in new ways. ATAP is even beginning to use Stratasys’ Digital Anatomy technology to improve functional material performance.

The PolyJet-based Digital Anatomy 3D Printer replicates the appearance, texture, and responsiveness of human anatomy, including tissue, bone, and muscle.

Designed initially to improve surgical preparedness and training and help test new medical devices, it has found a home with the Google ATAP Lab team designing devices that need to wear well on the human body.

“The closer replication of human body materials opens up entirely new avenues of exploration,” Allen says, adding that as 3D printing continues to evolve and improve, the final printed parts will even more closely match designer intent and real-world materials.

“Printers are really catching up to how designers think about design and materials. The future is coming a lot faster than we thought it would, and at Google ATAP, we’re building the capabilities for us to be able to predict what’s possible.”