Improved grease dispensers – not sexy, but very, very useful

The next stage of wringing every last efficiency out of GKN’s manufacturing and assembly lines includes printing replacement or improved parts to upgrade its production machinery.

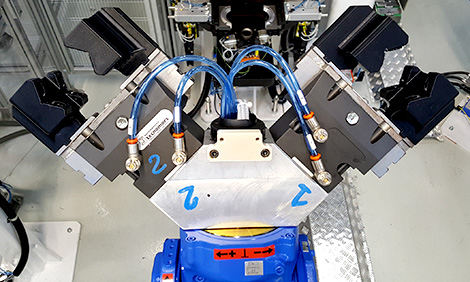

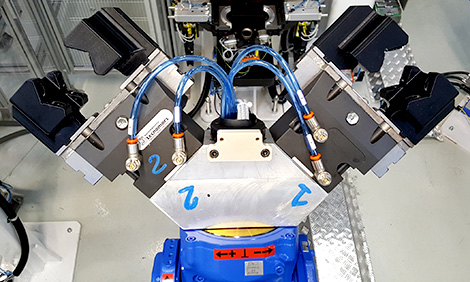

At its Driveline Florence plant, GKN is expanding the deployment of 3D printing across the manufacturing floor beyond jigs and fixtures, creating end-use custom parts for its robots and machinery, resulting in improved business performance.

The Florence plant churns out thousands of parts for Fiat Chrysler Automobiles Group each week, including its luxury marques Maserati and Ferrari, but to achieve such magnificent products needs exceptional achievements in the mundane – such as a redesigned and printed grease nozzle tool.

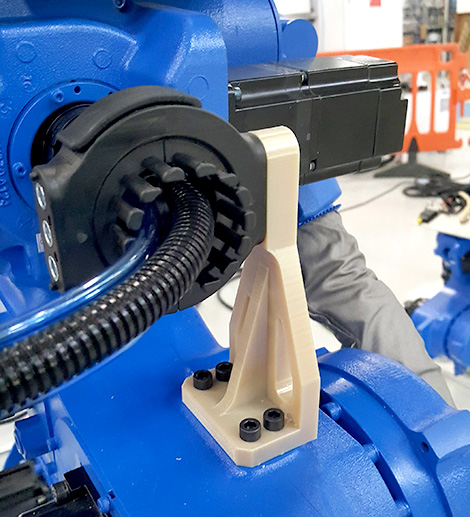

Custom cable clips for an industrial robot at GKN’s Florence plant were designed and printed quick and cheap in-house

According to Carlo Cavallini, GKN lead process engineer and team leader at the Florence plant: “Utilising our 3D printer, we developed a tool that dramatically improves grease distribution and eradicates the need to clean up time-consuming spillages.

“This has been crucial to streamlining the production cycle of the half shaft, enabling us to provide customers with premium quality final parts.”

To further improve efficiencies on the factory floor, the plant is also extending the use of 3D printing to produce customised replacement parts, on-demand.

Cavallini’s team recently 3D printed a missing cable bracket for a robot, saving at least one week versus the time it would have taken to receive the part from the supplier adding flexibility to its manufacturing and maintenance requirements across the production floor.

Through use of Cavallini’s team and its Stratasys Fortus 450mc 3D printer, the plant can quickly undergo feasibility analysis of the tools and deploy them on the factory floor significantly faster, accelerating the entire production schedule.

“Considering that we produce several thousand individual parts a week, this ability to manufacture on-demand is crucial to ensuring our production line is always operational and maintains business continuity.

“As we continue to design parts specifically for additive manufacturing, we are finding more and more applications that are delivering value.”

The division are also producing 3D printed bespoke end-of-arm tools, saving up to two months of labour time when compared to traditional methods.

“In the future, I believe that FDM 3D printing will become an integral part of our entire tool development cycle and help us further improve business performance,” he concludes.