The world’s foremost 3D printing event, held in Frankfurt, Germany in November 2024, was as busy as ever, despite market uncertainty and a wave of mergers and acquisitions. Stephen Holmes reports on his key takeaways from the event

Formnext 2024 – Focus on sustainability

Since its earliest days, proponents of 3D printing have frequently hailed it as more sustainable than subtractive methods – but companies in this market still feel they have more work to do in promoting it as a green manufacturing technology.

At almost every stand on the Formnext exhibition floor, suppliers were showcasing their latest sustainability enhancements, from new materials to new ways to reuse previously processed powders.

EOS, for example, introduced its HighReuse materials line, including ALM PA 950 HD and PA 2220, which boast recycle rates of up to 80% and 70%, respectively.

Stratasys went one step further with a new SAF ReLife software upgrade for its H series machines. This works alongside the company’s thermal controls for its SAF (Selective Absorption Fusion) process and enables Stratasys H350 machines to use waste PA12 powder which might otherwise be discarded, from any 3D printing process, including SLS and MJF.

Even more niche materials have seen improvements. Flame retardant PA12FR from Evonik, for example, is now capable of 50% reusability with HP Multi-Jet Fusion 3D printers. The polymer is also cost-effective, offering an alternative to injection moulding parts like electronics housings and battery holders.

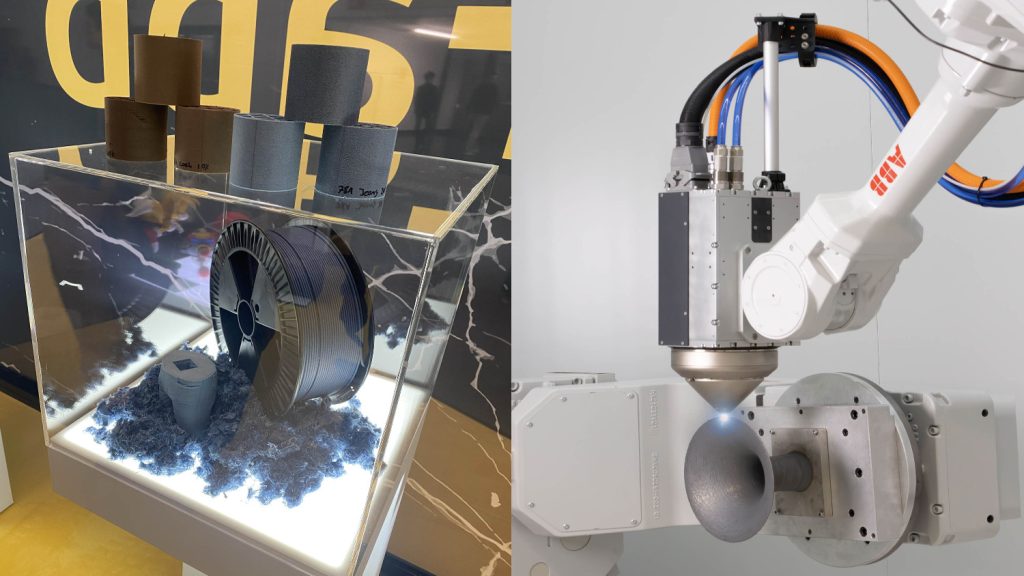

Most notable were the materials from ColorFabb, a company already known for its wide range of colour FDM filaments, but also for using waste products in its materials, such as bamboo and cork.

The Dutch brand finds use in industrial waste and off cuts, and this year showcased filaments made from denim jean fibres and used polystyrene packaging, as well as a fully biodegradable material. Given the wide range of choices it offers, ColorFabb is a name to note by anyone with a professional interest in ESG (environmental, social and governance) issues or CMF (colour, material, finish) matters.

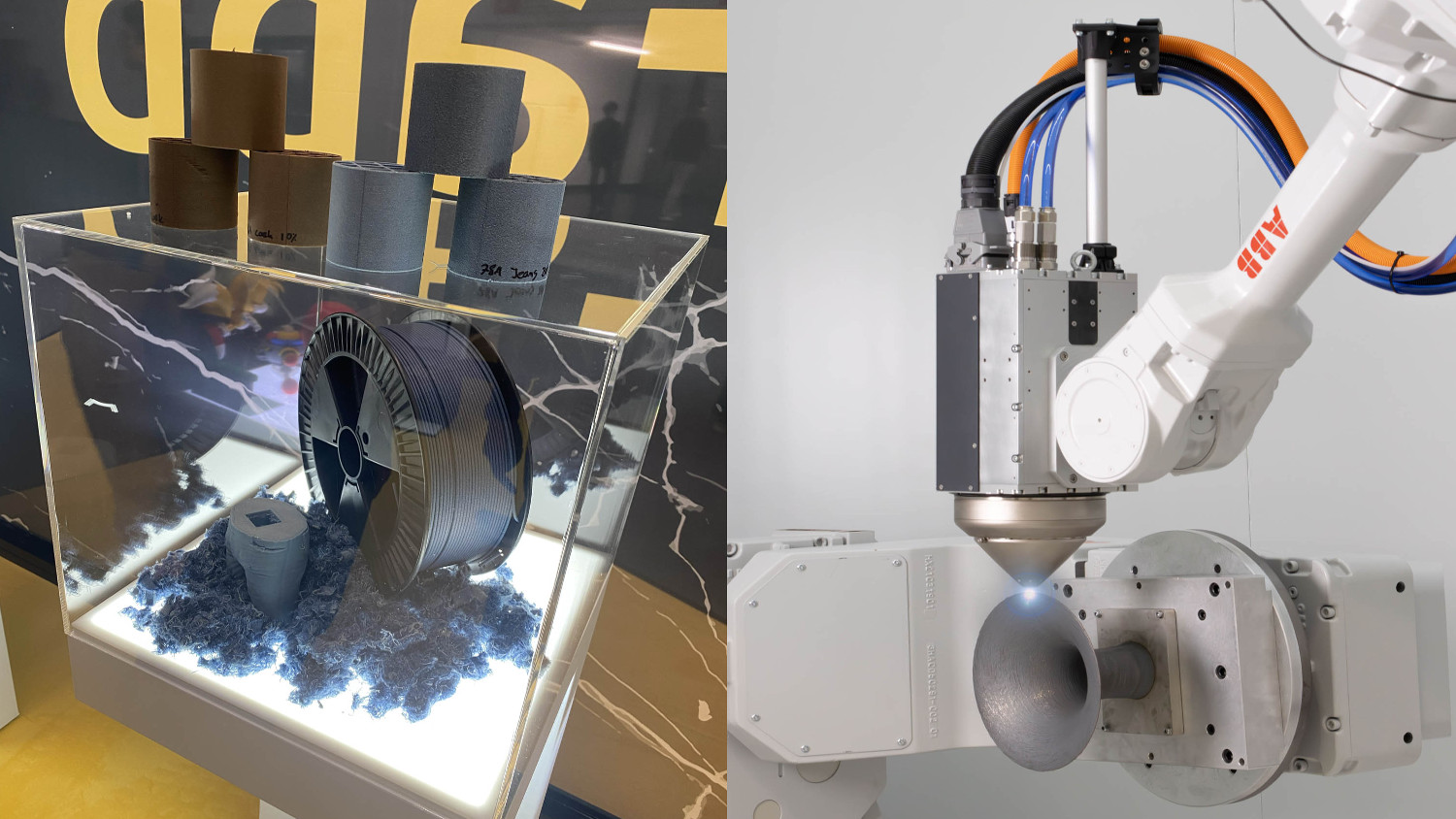

Even power-hungry elements like lasers are evolving in an environmental direction, with bright sparks like Meltio adding new blue laser technologies that consume 30% less power, while also reducing the weight of the robot arms and gantries on which lasers are mounted. Smaller, lower power units are the way forward, it seems.

Formnext 2024 – Getting the spark back

With the dust starting to settle from a flurry of mergers and acquisitions – some that happened, some that very publicly did not – big names in the industry are getting back to the important business of adding more innovative technology to their platforms.

The large Stratasys stand, for example, was full of upgraded tools and materials, from a new filament drying cabinet for longer FDM prints on its Fortus F900 machine, to over 30 new materials for the Origin P3 resin platform.

3D Systems, meanwhile, unveiled the PSLA 270, a highspeed, projector-based SLA 3D printer, which drew a great deal of interest from the crowd and is supported by the now mature Figure 4 materials portfolio.

There was also a scrum around the Formlabs stand, with attendees keen to see the Form 4 and Form 4L printers. While there were plenty of other lower cost desktop SLA printers on show at Formnext, it was clear that professional users really value the design and build quality represented by the Formlabs brand.

Formnext 2024 – Has desktop FDM peaked?

In a swamped market characterised by both a headlong rush to offer lower prices and an uptick in performance and output quality from brands that include (but are by no means limited to) Bamboo Labs and Prusa, desktop FDM machine development appears to be slowing.

Brands such as UltiMaker – which combines the work of two former pioneers of small-format FDM – may continue to offer high-end desktop machines, but its sights seem to be set on more industrial customers with its Factor series. The Factor 4 offers all the bells and whistles you’d expect from a machine in this industrial category – something it has in common with many of the other medium-sized FDM 3D printers we saw at Formnext, which are targeted more at factor floors than design studio workbenches.

Tellingly, there were no new desktop FDM launches at this year’s show, at least not from the major western brands, which suggests that customer interest in this sector may have peaked.

Formnext 2024 – Slicker software

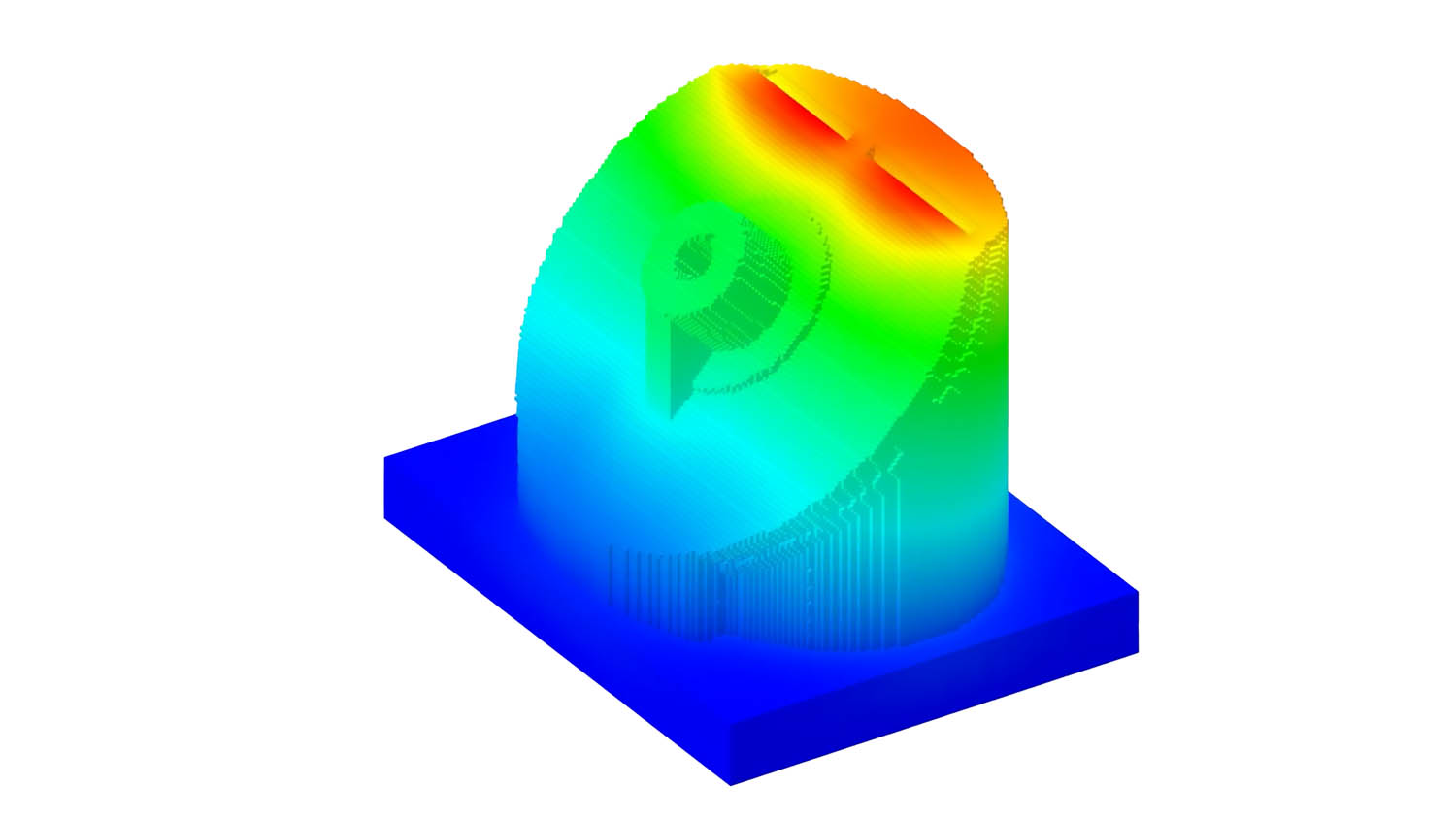

Formnext 2024 was a great showcase for a healthy number of software options for additive manufacturing, designed to help users handle design, process control and simulation, among other tasks.

There were demos from newer brands like Synera, which builds software for automating workflows and for connecting diverse tools, and Cognitive Design Systems, which focuses on generative design and automated build process screening.

High levels of interest in software demonstrated a shift in the Formnext attendee demographic, from those just there to kick the tyres of physical machines to those looking to gain real competitive advantage from additive manufacturing. The printer manufacturers were also keen to tout their partnerships with innovative software providers, with names like nTop, Hexagon and Altair prominently displayed on their stands.

There was drama surrounding China-based software company VoxelDance, which was at Formnext to show off an all-in-one pipeline that incorporates implicit modelling, build preparation and simulation. Accusations of IP infringements, however, brought German customs investigators to the company’s stand and product demonstrations to a halt. It remains to be seen how this skirmish will play out and what wider impact any legal dispute will have.

Names familiar from the CAD world were there, too, including Catia, Onshape, Siemens and Autodesk, using Formnext to explain how additive workflows are now firmly entrenched in their software packages as they increasingly aim to whittle away at the influence of specialist software such as Materialise, with its Materialise Magics product.

There was greater software support, too, for the printer makers. Executives from Tech Soft 3D were eager to highlight that their product is a backbone to many tools and services found in additive workflows, while those from Australia-based Visionware 3D were promoting the company’s turnkey services and support aimed at building everything from custom 3D printing engines to control systems for vendors.

Formnext 2024 – Fresh attempts to deliver on earlier promises

Brands at Formnext showed a renewed determination to deliver on elements such as colour parts and 3D printed electronics, helping additive shift from prototyping to real-world parts.

Stratasys showed off how it has been working alongside Italian packaging expert Baralan, so that its PolyJet technology can be used to create forms more commonly associated with traditional manufacturing methods – such as glass perfume bottles – and bring new textures and full-colour designs into play. Enabled by a specially developed primer and protective coating, Baralan sees this technology as an exciting way to add bespoke details to luxury products and support short production runs.

A Stratasys rival in the colour 3D printing stakes, Mimaki, drew crowds with the lifelike realism of its prototyping and display models and its dedication to achieving industrystandard, repeatable colours in the additive space.

A big highlight of the event for many, however, was to be found at the Nano Dimension stand. Having hit the headlines over the past year for its acquisitions of Markforged and Desktop Metal (among others), Nano Dimension execs impressed attendees with the company’s Dragonfly 3D printed electronics and micro 3D printing capabilities.

In particular, Dragonfly’s use of conductive inkjet 3D printing is capable not only of producing one-off PCB prototypes, but also an array of end-use parts.

Fully working 3D-printed motors, embedded electronic drone chassis and compact aerials made the Nano Dimension stand look like a scene from a James Bond movie set in Q’s laboratories.

While all this activity prompts many to wonder about Nano Dimension’s long-term intentions, it’s clear that a world unshackled from traditional PCBs and wiring looms is one that many Formnext attendees would welcome.