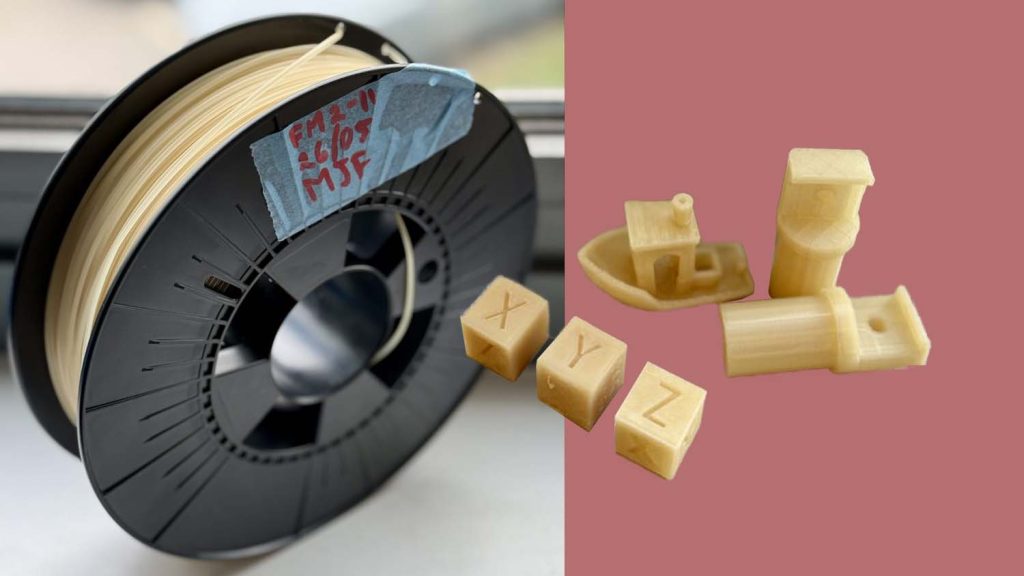

Filamentive, working with recycling hardware specialists 3devo, is developing a new FDM 3D printing filament made from nylon powder waste from MJF 3D printing.

According to Filamentive, MJF PA12 and SLS workflows can result in over 50 per cent of powder going unused after each print. For a busy print setup, this can add up to more than 1,000 kg of wasted PA12 powder every year, representing not only a sustainability issue but also a significant cost burden, considering that some PA12 powder costs upwards of $100 per kilo.

Much of the waste powder can end up in landfill or incineration, where it contributes to plastic pollution, microplastic leakage, or harmful emissions, and in the UK alone, Filamentive estimates that an estimated 400,000 kg of plastic is wasted annually from 3D printing, increasing the urgent need for sustainable solutions.

Because PA12 remains a thermoplastic, it can be melted and reshaped into a usable filament for 3D printing, a process being pioneered by additive manufacturing power users like BMW and in the UK by 3devo.

Current extrusion trials are ongoing at 3devo as the teams refine the process to improve both printability and mechanical performance of MJF PA12 filament.

“Filamentive has also engaged experienced nylon 3D printing customers to test early batches, giving us valuable real-world feedback to help fine-tune the material for professional applications,” said Filamentive managing director Ravi Toor. “All being well, the aim is to launch recycled PA12 Filament in early 2026.”

The company is looking to identify UK waste streams of unused MJF PA12 powder, as well as for operators that use a high volume of Nylon filaments, and is open to connecting with any businesses that could assist. You can contact them here.