Evonik and HP have together developed a new thermoplastic elastomer for HP’s Multi Jet Fusion 3D printing technology.

The new flexible, ‘high-performance specialty powder’ is based on a thermoplastic amide grade (TPA) for 3D printing.

The new Evonik and HP TPA powder is a lightweight, low density (1.01 g/cm³) material with a Shore A hardness of 91, making it ideal for parts that call for high extensibility and energy return, such as sports equipment or automobile components.

“Open collaboration with materials leaders like Evonik continues to be so important as we push the boundaries of additive manufacturing and accelerate the industry,” said Tim Weber, global head of materials, HP 3D Printing and Digital Manufacturing.

“We are excited to continue building on our long-standing partnership with Evonik to deliver another compelling material for customers and expect to see innovative new applications that take advantage of TPA’s flexible, lightweight properties.”

Head of Evonik’s new 3D printing technologies market segment at Evonik, Sylvia Monsheimer, praised the work between Evonik and HP experts to produce the high-performing material.

“The new TPA is a perfect example of successful collaboration between Evonik and HP—that is, between the materials and the technology aspects of 3D printing—to develop the perfect printing parameters in close conjunction, so as to finally allow a smooth and trouble-free printing process,” he said.

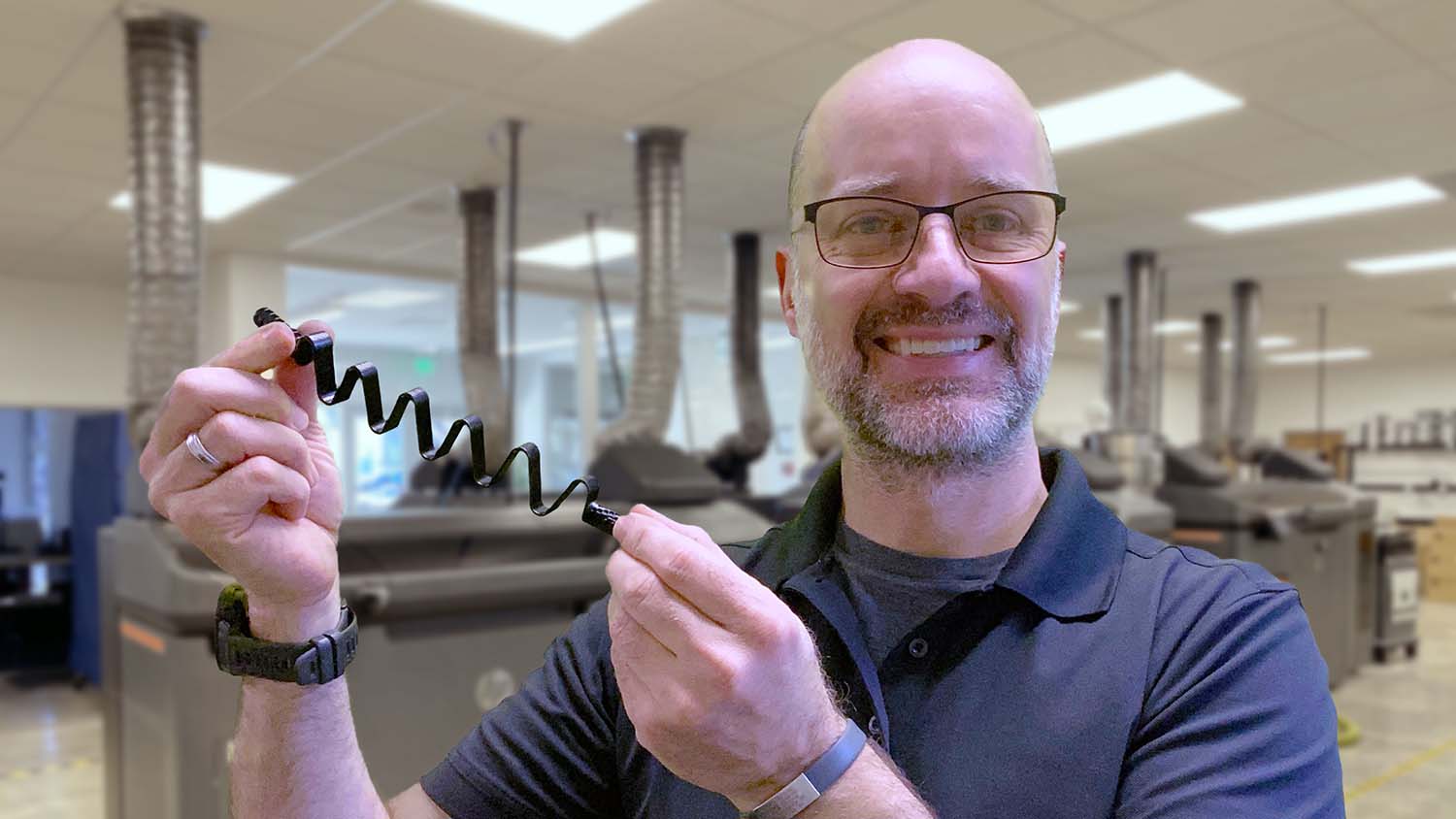

HP 3D printing customers, including US-based rapid manufacturing partner GoProto, are already developing new applications that utilise the material’s properties.

“We have had customers make ducts and bellows and footwear, athletic equipment, wearables and harnesses/connector parts,” explained GoProto CEO Jesse Lea. “The combination of production quality material properties like high wear resistance, energy return, longevity and light weight continues to impress at every application.”

Evonik also revealed a new brand identity, Infinam, for its 3D printing materials.

“Infinam gives our customers and partners clear orientation within our product landscape for additive manufacturing. Along with our key visual and our promise (“Infinity meets reality”) of opening up infinite 3D applications with Evonik materials, the new product brand plays an essential role as the final element in our unique market identity,” said Thomas Große-Puppendahl, head of the additive manufacturing innovation growth field at Evonik.