E-Stage for Metal+ has been launched by Materialise as a software to optimise data and build preparation for Laser Powder Bed Fusion (LPBF) systems using physics-based modelling to automate support structure generation and increase economic viability.

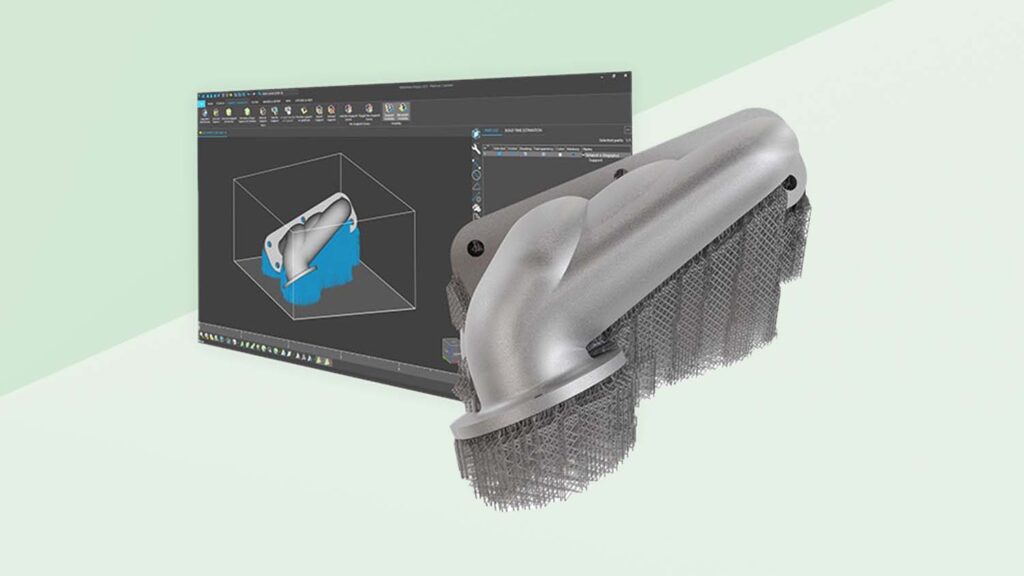

The new module for Magics, Materialise’s data and build preparation software, e-Stage for Metal+ calculates where deformations during the 3D printing process will occur and automatically generates needle-thin and cone supports where needed.

Combining the two support types optimises stability and heat distribution during the 3D printing process, helping to avoid part deformation while reducing post-processing efforts.

“Metal AM users tend to overload parts with support structures during manual data preparation,” explains Ian O’Loughlin, metal practice lead at Materialise. “They want to avoid defects and the costs associated with reprinting the parts. That’s why intelligent tools like e-Stage for Metal+ are crucial.

“Automating support structure generation at the sweet spot of printability and required supports saves time, material, and post-processing costs.”

According to an independent survey commissioned by Materialise, LPBF is the leading segment for additive manufacturing, accounting for over 52 per cent of the industry’s global revenue in 2022, while remaining a relatively complex technology to operate.

According to the study, the two main factors holding companies back from adopting 3D printing are a lack of knowledge and the cost associated with the production process. Both challenges play a central role during build preparation for LPBF.

Materialise explains that e-Stage for Metal+ helps remove the compromise between part quality and overall production costs, offering companies ‘a fresh perspective on their complete LPBF process by making it more economically viable and straightforward to adopt’.

“By automating support structure generation with Materialise’s software, you can streamline your 3D printing process,” says Mirco Schöpf, product line manager for software at 3D printer manufacturer EOS. “It simplifies support removal, reduces support volume up to 80 per cent, eases powder extraction and decreases build plate machining after an effortless part removal.