The new BAC Mono R

Briggs Automotive Company (BAC), the British manufacturer of the recently launched Mono R, has managed to slash its design and development timescale with the innovative use of functional 3D printed prototypes.

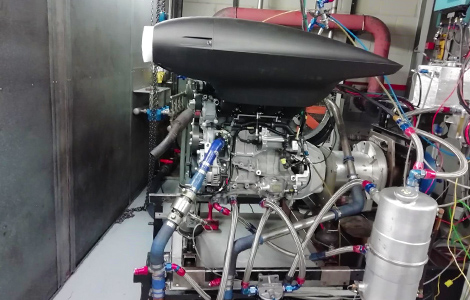

With the aid of its reseller, Tri Tech 3D, BAC used the Stratasys F900 3D printer to produce a prototype engine airbox able to withstand speeds of over 170mph and temperatures above 100 degrees celsius using Stratasys’ Nylon 12CF material, A carbon-fibre reinforced thermoplastic.

“Access to quick, efficient, industrial-grade additive manufacturing was a game-changer for this development process,” said BAC design director Ian Briggs.

The finished article

“Within hours we were able to produce an accurate 3D-printed prototype of the airbox and install it on the car for testing. This enabled us to reduce our design-to-manufacture time significantly.

“We were able to tweak the design and not worry that the final 3D printed version wouldn’t match the exact size or geometry we needed,” Briggs summarises.

The airbox in testing