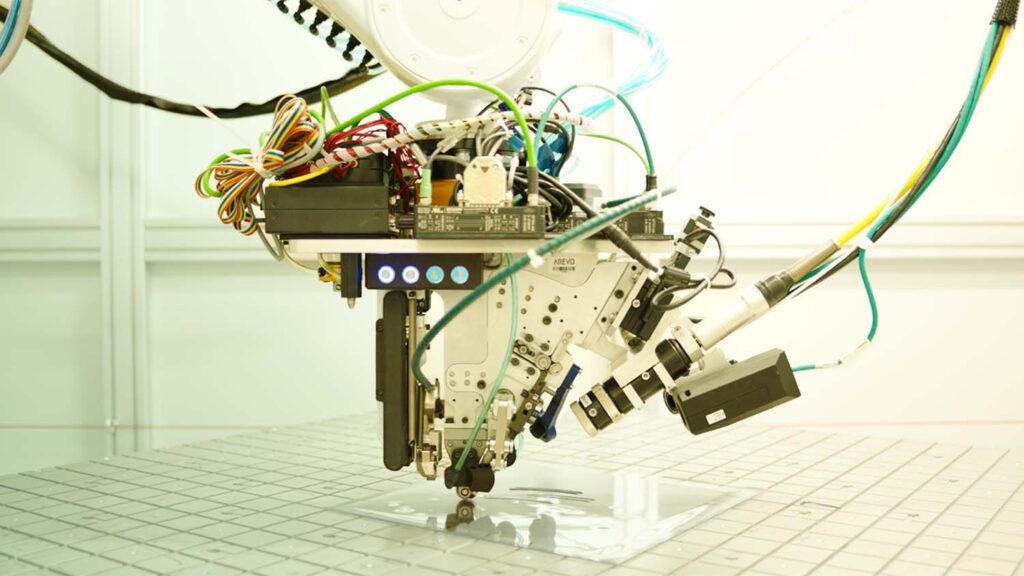

Arevo has announced Aqua 2, its newest high speed additive manufacturing system for large continuous carbon fibre composite structures.

Arevo states that in addition to producing higher quality parts than its forbearer, the Aqua 2 is also able to print four-times faster.

This should enable rapid, on-demand production of large custom composite parts, up to one cubic metre in size.

The Silicon Valley headquartered company is looking to automate the design and fabrication of large, geometrically complex, continuous CFRP composite products through a suite of innovations in materials science, robotics and design software.

Arevo states that its customers already include companies from consumer, industrial, automotive, heavy industries, construction and aerospace sectors.

The launch of the new Aqua 2 System comes shortly after Arevo closed its Series B financing, led by Defy Partners and GGV Capital, which takes the start-ups’ total funding to $60 million.

“Arevo’s new platform enables fabrication of high strength, low weight carbon fiber parts, currently not possible with today’s standard techniques,” said Defy Partners founding partner Trae Vassallo.

“We are thrilled to be working with the team to help scale up this incredibly impactful technology.”

“The strong interests in the company despite tough market conditions really reaffirm our vision,” said Arevo chairman Hemant Bheda.

Arevo has already made a name for itself through a crowdfunding campaign to make its first direct-to-consumer products, the Superstrata bicycle and e-bicycle, a unibody custom 3D printed carbon fibre bike.

The campaign hit its goal of $100k in under 3 minutes after launch, and is now on track to surpass $5m from over 3,000 backers.