Additive Works has been acquired by 3D Systems to expand the simulation capabilities of its technologies for ‘rapid optimisation’ of industrial-scale 3D printing processes.

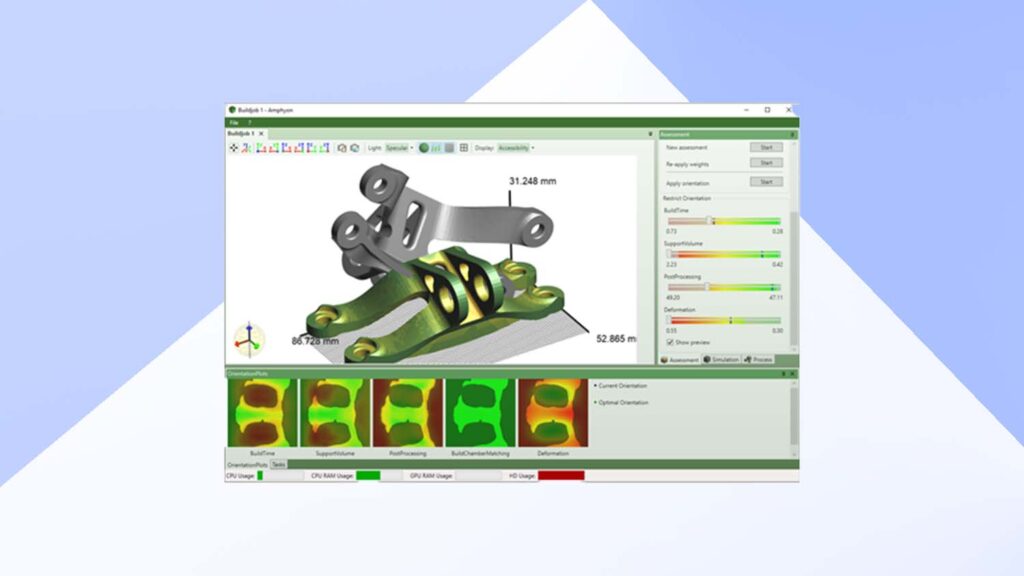

Additive Works’ software offers optimisation of parts for ‘first-time right’ 3D printing using laser beam melting processes, examining all the possible build orientations to find the best part quality and most economical option, while also highlighting the limitations of the design and orientation.

With both polymer and metals processes in its stable, 3D Systems is clearly focussed on the industrial growth of 3D Printing and the need to support users scaling-up productivity, yield and performance.

3D Systems existing 3DXpert software, launched in 2016, already covers the AM workflow from part design to post-process finishing, with Additive Works’ teams set to add to this.

Additive Works Amphyon and the Amphyon plug-in for CAD users will continue to be sold and supported to customers as a standalone offering.

The result, says 3D Systems, is a faster, more reliable manufacturing process, reduced part cost, and improved component performance.

Integrating Additive Works’ simulation expertise into 3D Systems’ software team will enhance the company’s AM software portfolio and innovation capacity, driving accelerated additive manufacturing adoption across the industrial and healthcare markets that the company serves.

Commenting on these two acquisitions, 3D Systems CEO Dr. Jeffrey Graves said: “We continue to deliver on our four-phase plan with an increasing focus on investing for accelerated growth and profitability.

“I’m excited by the expertise, capabilities and technologies we are adding to the 3D Systems portfolio with Allevi and Additive Works.

“These investments will bring added value to our customers, open new markets for our technology, and result in accelerated growth and profitability that will allow 3D Systems to thrive in the exciting years ahead.”