Following our review of the Ultimaker S5, we’ve compiled 5 easy to implement tips and tricks to help you benefit from its slicing software, Cura.

There’s an argument that the desktop FDM printer industry is about maxxed out in terms of hardware development.

While the majority of the work had been done decades ago by Stratasys, we’re now in the time where others wait for patents to expire so they can take advantage of that development in lower cost machines.

As a result, what is becoming more critical in the advancement of this class of machines is software control and how it’s able to provide the user with new benefits, without having to wait for hardware changes.

This is where Ultimaker, and the Ultimaker S5 specifically here, benefits as it also develops one of the few slicing applications Cura (as well as licensing it out to other vendors, such as Lulzbot, also).

It’s worth digging into some of the advanced and experimental options inside Ultimaker Cura to see if there’s anything worth taking into your workflow.

5 3D Printing tips for Ultimaker S5 and Cura 4

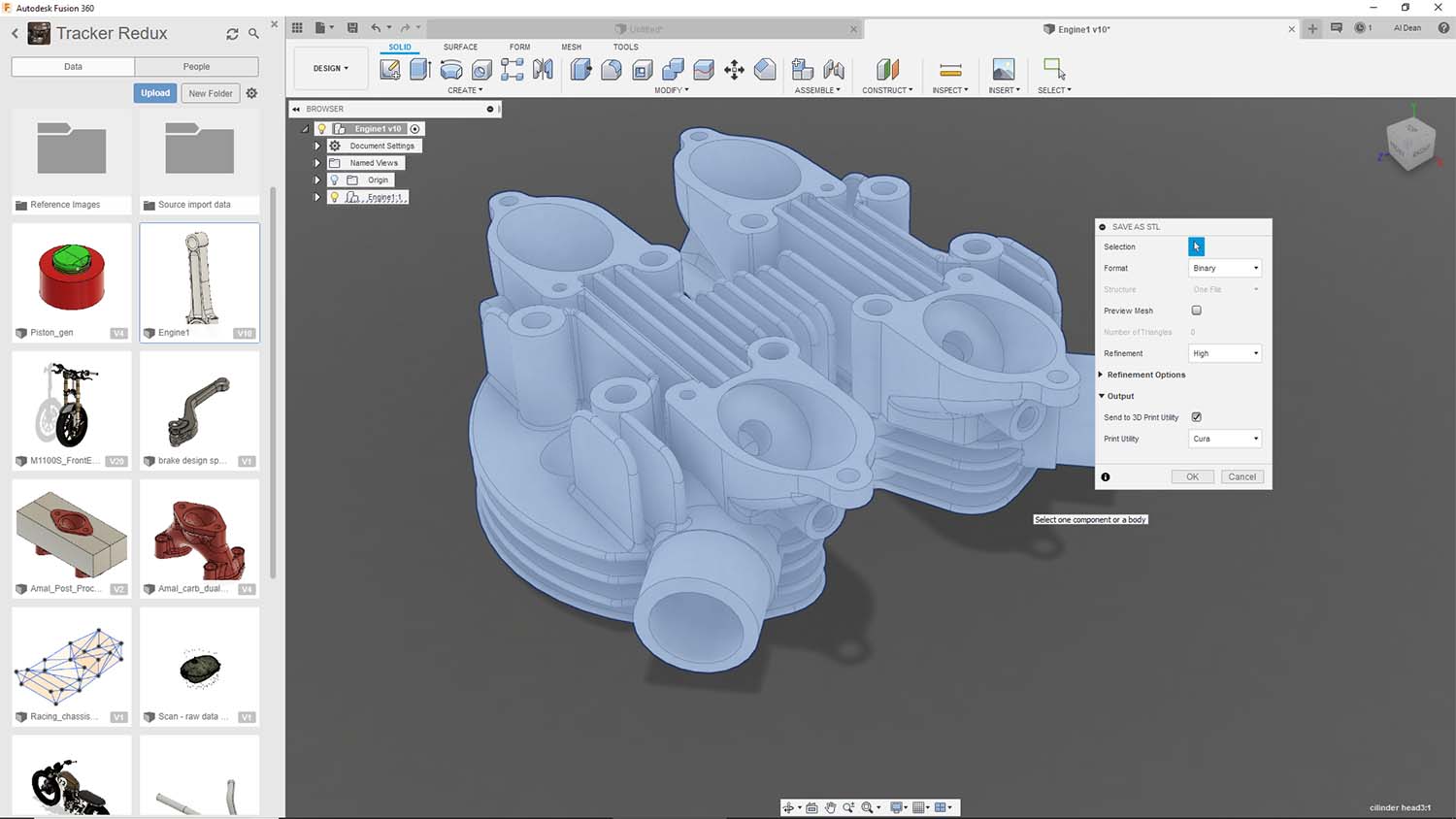

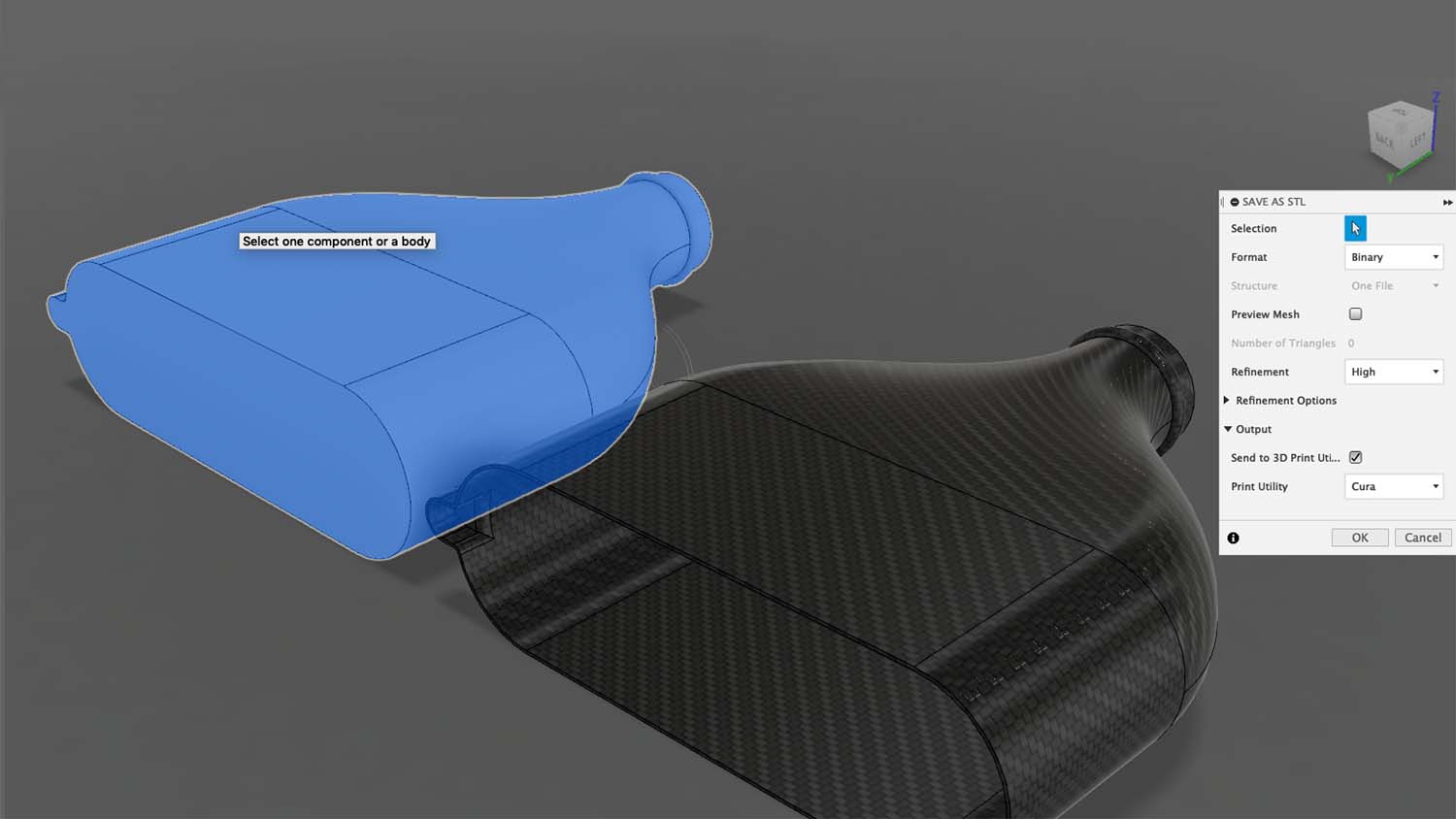

1 CONNECT TO CAD

Ultimaker has been doing a nice job of integrating Cura with various CAD applications (at present, Solidworks, Fusion 360 and Solid Edge) – gives you a much nicer workflow, particularly for multi material builds

2 SOLUBLE SUPPORT OPTIONS

Another experimental feature in Cura 4 is the ability to reduce the use of your costly dissolvable PVA filament and have the system build the bulk of supports using your PLA/ABS etc, then top out with PVA

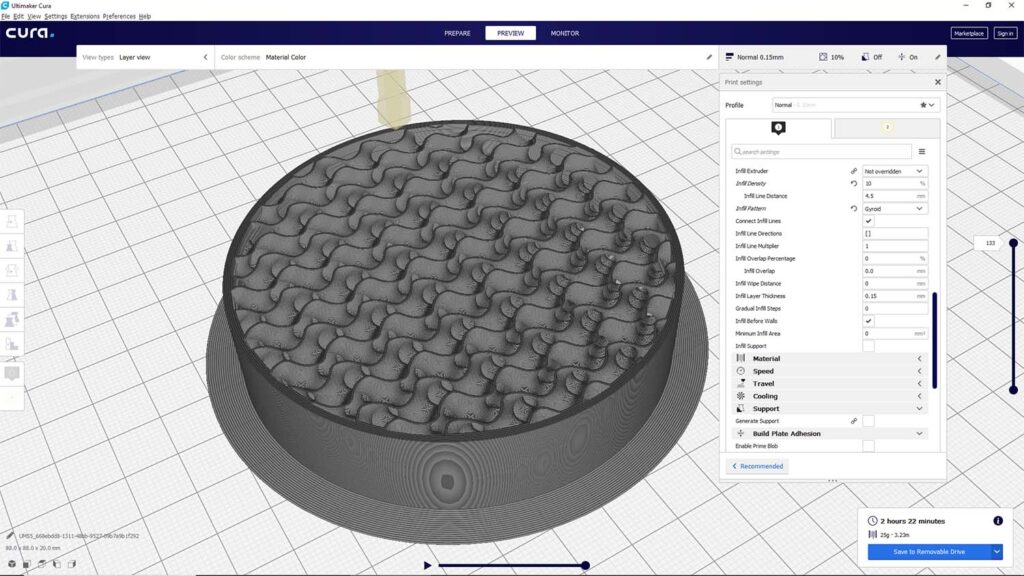

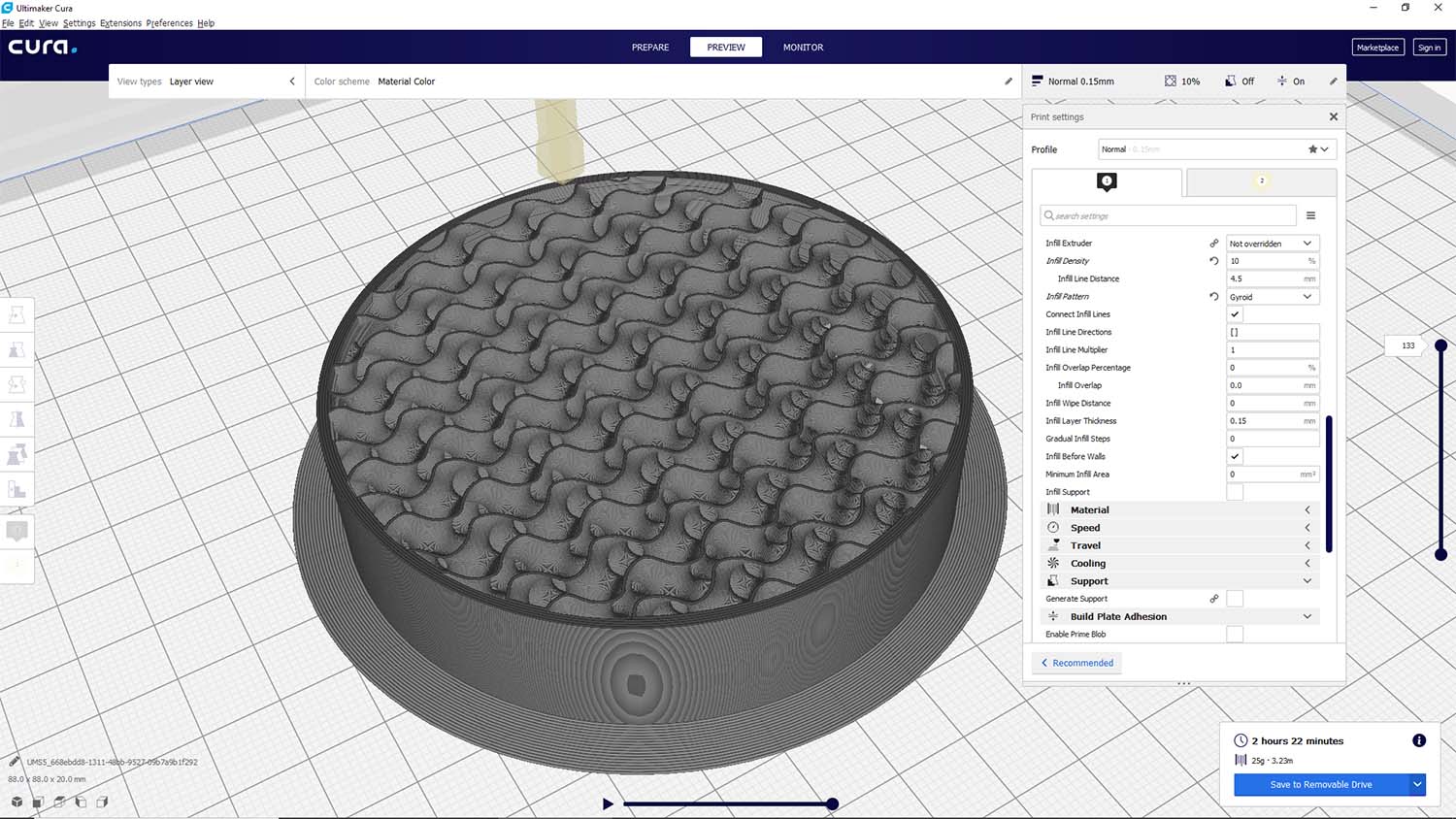

3 GYROID INFILL

Alongside the gradual infill options in Cura, there’s also a new gyroid option. These forms are fascinating (discovered in the 70s by NASA scientist Alan Schoen) and give excellent strength to weight for internal part supports

4 DISSOLVABLE CORES

This one isn’t so much about Cura, but the ability to switch your soluble PVA to your main extruder to build soluable formers or patterns might prove useful – particularly for prototype composites

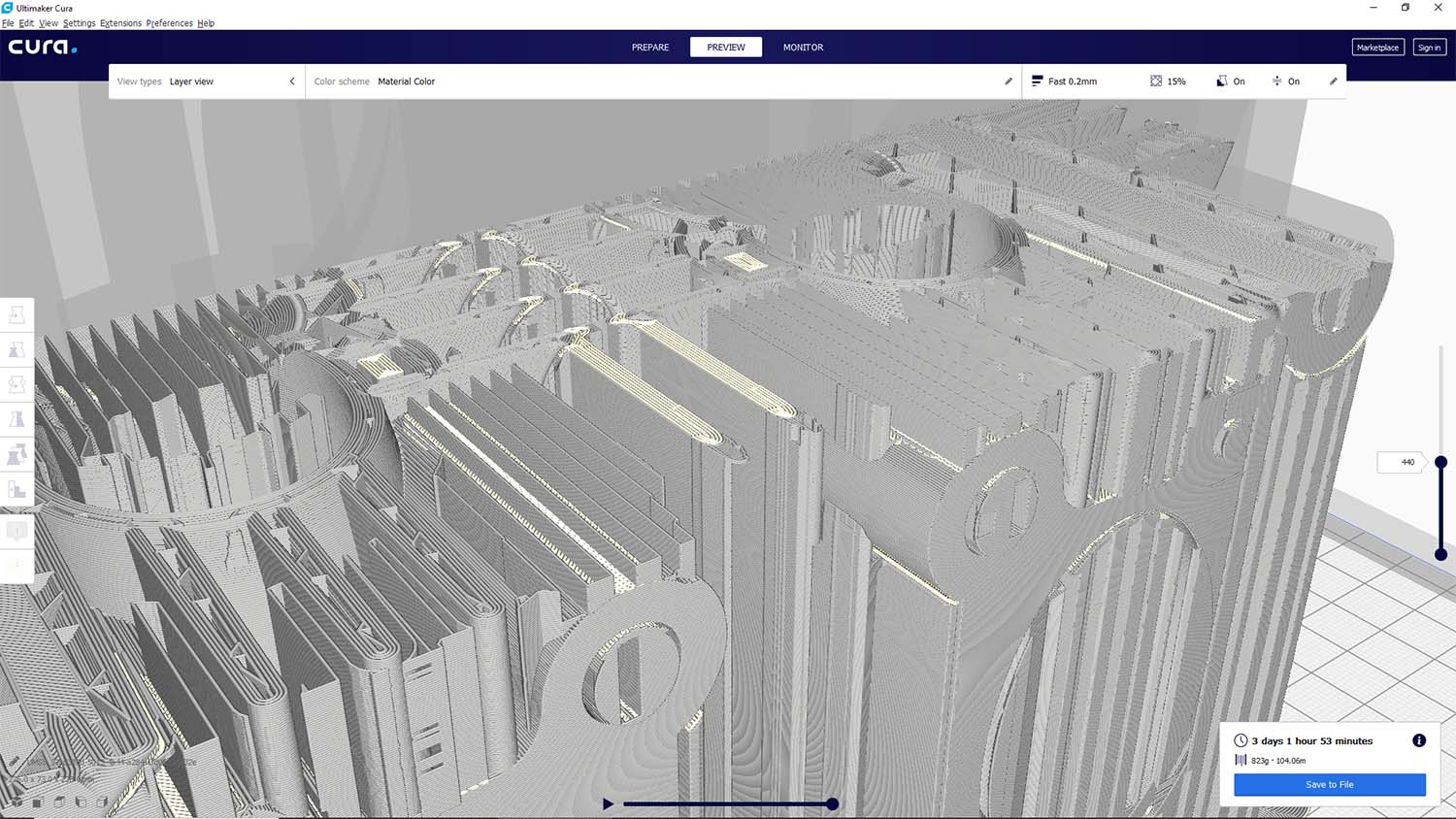

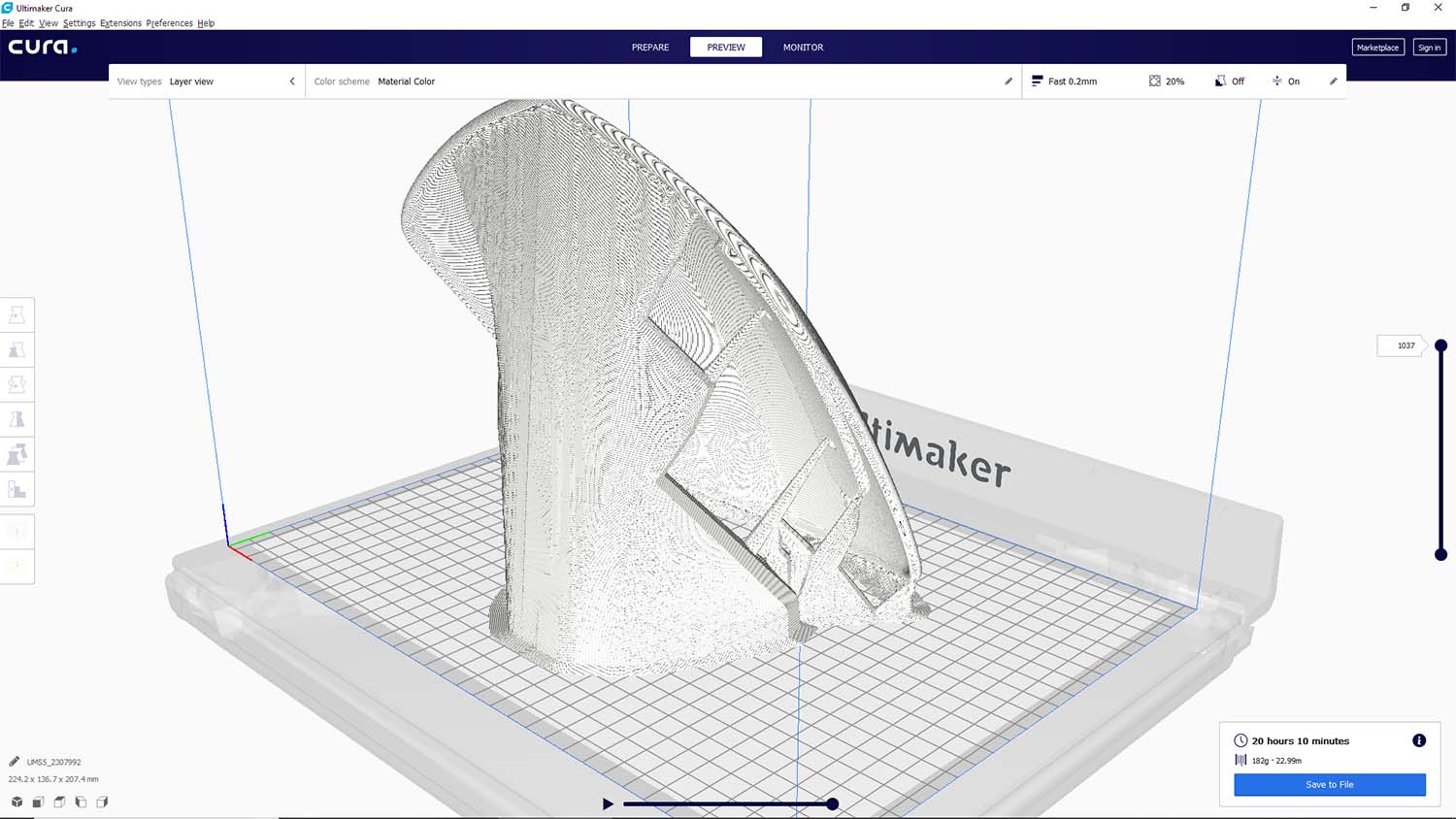

5. TREE SUPPORTS

I’ve loved this since I discovered it. It builds incredibly efficient support structures exactly where you need them, with minimal lost material and minimal touch points – it also builds a lot quicker that the monolithic method

Want More?

Read our full in-depth review of the Ultimaker S5 3D printer here