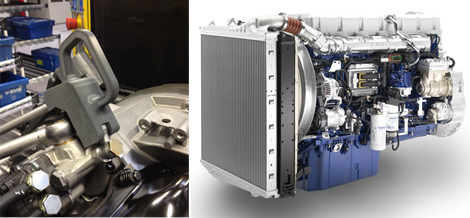

Volvo Trucks is using 3D printed tools to help make the assembly of vehicle parts, like its engines, faster, cheaper and more flexible

Designing tools for assembling products is a full-time hassle in itself – hence why those with thousands of components to piece together are looking to 3D printing to speed up the process.

Volvo Trucks’ engine assembly plant in Lyon, France (it makes parts for Renault Trucks too, with the Swedes having bought it a while back), is using Stratasys’ Fortus 3D printers to build jigs and fixtures for the assembly line staff, reducing the time it takes from 36 days to two days.

The speed comes as a factor of not having to build these in metal, which also means that it’s cheaper too – especially where customised or small quantities of tools are needed.

With the parts being 3D printed from plastic they are much cheaper and easier to add design features to – such as benefitting the ergonomics of the user

According to Pierre Jenny, manufacturing director at Volvo Trucks, these gains are also improving the production plant’s overall efficiency and flexibility; delivery times are upheld and the use of additive manufacturing has saved costs by reducing wastage.

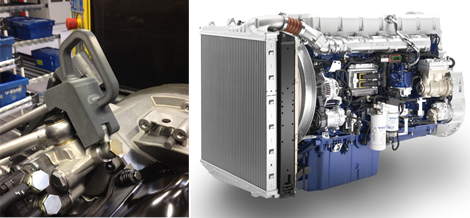

Within a three month period Volvo had 3D printed more than 30 different production tools to facilitate the way its production line operators worked, including a range of different durable yet lightweight clamps, jigs, supports and ergonomically-designed tool holders that ensure a more organised working environment for operators.

“We’re working in the heavy-industry sector, so reliability is naturally critical: so far every piece that we have 3D printed has proved to be 100 per cent fit-for-purpose,” said Jean-Marc Robin, technical manager, Volvo Trucks.

“This is crucial from a practical aspect, but also instils trust among operators and quashes any traditional notion that everything has to be made from metal in order to function properly.”

According to Robin, developing production tools using additive manufacturing also enables the equipment design team to be far more responsive, while avoiding possible wastage in the event of last minute design changes before tools are made.

In cases where the design specifications of a traditionally-manufactured metal tool’s were inaccurate, the lengthy and costly design and manufacturing process had to begin again.

With a 3D printed part the design specifications and re-printed in a few hours.