Inventor has now been on the market for a good 15 years. Having been launched as a move away from Autodesk’s AutoCAD-based Mechanical Desktop, Inventor has gone on to be the mainstay in the widespread adoption of 3D modelling-based design systems.

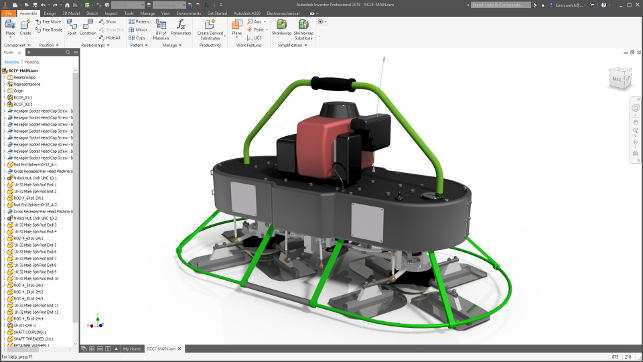

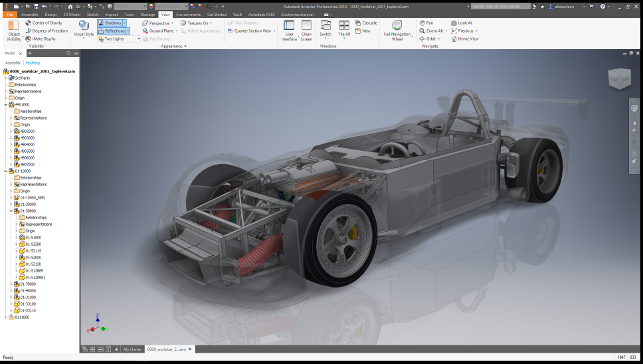

Fig 1. Performance has been a focal point for this release, letting you work with large assemblies more efficiently — both in design and when creating drawings

Let’s delve into the 2018 release by firstly looking at the part and assembly modelling tools that we all use on a daily basis. As ever with mature systems like Inventor, these are always going to be iteration rather than innovation but that doesn’t mean there aren’t some nuggets of goodness in there, as there most certainly are.

For me, one of the most interesting is an update to feature limit options. While every system has the usual array of options for extruding distances, to faces and to offsets, it’s when you get into the finer points of such features that things really start to get intelligent and reduce those complex work-arounds.

A good example is the addition of ‘distance from face’ to the extrude operation. This not only allows you to project a 2D curve onto a face as the starting point, but to set the limits for that extrude (whether you’re adding or removing material) as a distance from a face. This isn’t the same as a face offset, rather it allows you to define a relationship between the geometry of that feature and any other face in your model.

It’ll save you time as well as make feature histories more robust as the system does the donkey work that previously would have required a couple of features to achieve the same end result.

Another solid update is a small one made to the hole command, which traditionally built features in the direction of the hole.

The new addition called ‘extend start’ allows you to build backwards from the placement plane so geometry is cut away, this would have previously needed a secondary sketch and cut.

The last one is the ability to add a partial chamfer to an edge. This allows you to define the distance along an edge (or chain of edges) or the chamfer length specifically. Again, this reduces secondary features or work-arounds and for those designing fabricated (in particular, welded) assemblies this will be like manna from heaven.

Moving onto assembly modelling, the big focus for this release is performance.

As ever, users are building more complex and larger datasets — enabled by higher powered computing and demands of richer models. That said, it doesn’t mean that vendors can’t address performance improvements. For 2018, this focuses on providing easier access to Express mode when opening larger assemblies (not available in Inventor LT).

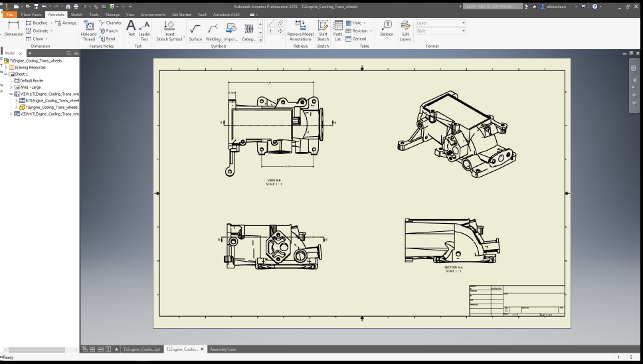

There are some additional performance updates elsewhere in the system as well. A good example is the delay introduced into drawing view generation. This lets you dial in the scale for the view with the view starting to generate, which means you can nail it down then have the system perform the computation.

Fig 2

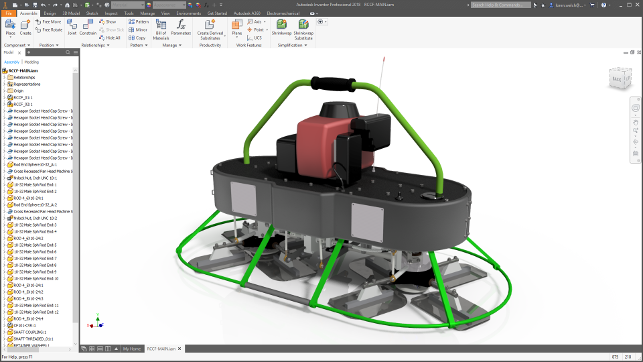

Fig 3. Inventor 2017 saw greater support for working with mesh-based data formats, such as this NX native data. In 2018 this has been extended to allow the use of such part geometry in drawing view creation

Measurement tool

Given that much of any design or engineering project centres around measurements, it’s perhaps surprising that the measurement tools in most 3D design systems are awful — overly complicated and, in many cases, split across multiple commands or weird workflows. Inventor was historically no different.

For the 2018 release, the measurement tools have been consolidated into a single dialog — your geometry selection will drive the measurements displayed, angles are much easier to gather and you’ve got dual units, which is useful for those that have to mix and match.

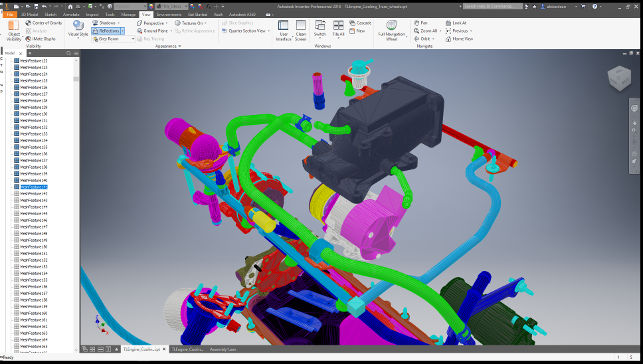

Fig 4. Inventor is building up a nice set of tools for not only working with large native assemblies, but also working more effectively with imported data (this is an example from Creo)

Data exchange and support

Recent release cycles have seen Autodesk introduce the concept of AnyCAD which allows users to work more effectively with third party data. It’s important that those who haven’t experienced data exchange tools understand the fundamentals. These tools are often marketed as “removing the pain of translation”. The reality is that there is still translation occurring, but the systems have become more adept at hiding the process from the user and maintaining the link to the originating file.

AnyCAD allows you to read in native data, but not ‘convert’ it per se. Rather, where that data is loaded it’s linked back to the original file. So if your Siemens NX data changes, you immediately get an update where that data lies in your assemblies.

For Inventor 2018, the AnyCAD tools build on the work from previous releases (which now include the ability to not only load native, proprietary fi les such as Siemens NX, Catia V5, SolidWorks et al, but also STEP files) and the versions have been updated, most notably support for Catia V5-6R2017. It’s also worth noting the moves that Autodesk has made to make Inventor backwards compatible. If you’ve got the Inventor 2017.4 release running then this can also read data from 2018.

While this will be of benefit to those working in sub-contract situations, within a supply chain or in regular receipt of customer or partner data, the key update for 2018 is with mesh data, which builds on the capabilities introduced in the 2017 release. Not only could you import mesh geometry and display it alongside more traditional solid and surface geometry, it also allowed you to do more with that mix of data types. Meshes could be actively used within assembly, assembled, interference checks run and much more.

This was also extended to allow the creation of basic geometry types of mesh data and was particularly useful for those with resultant data from laser scan processes that needed to ensure good fit between scanned articles and their own parts. This release doesn’t add much to this set of functionality, but rather adds the ability to use those mesh forms in downstream documentation, namely in drawings.

As shown in Figures 2 and 3, you can read complex data contained in mesh files (in this instance, from mesh geometry held in a Siemens NX assembly) and use that within drawings. While the drawing views aren’t quite as you get from surface or solid geometry (there’s some seriously impressive mathematics going on under the hood to interpret mesh edges), they’re more than useful for representing this type of geometry.

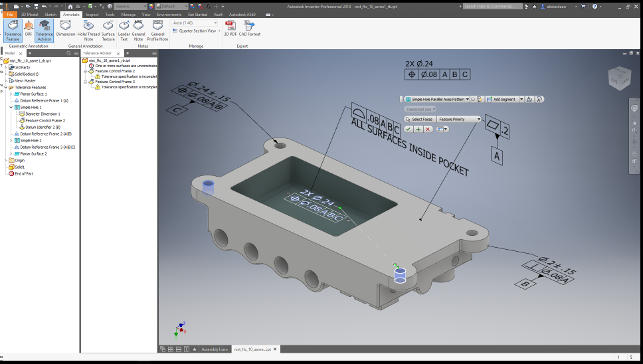

Model-based design (MBD)

If there’s a headline addition to the 2018 release, then it has to be Model-based Design (MBD). Although this term varies across vendors and industries (Siemens, for example, refers to it as Product Manufacturing Information), the result is the same.

If you’re unfamiliar with the term, it is the act of using your 3D model as the container for not only the geometry of your part, but also the critical annotations, dimension and tolerances you’d typically place on a 2D drawing.

While we’re all used to fully detailing 2D drawing views to capture this information, the process of adding it to 3D models is more complex. After all, you’re looking to link not only 2D drawing view entities to dimensions, but in this brave new world, to 3D geometry too. As such, the tools used to accomplish this are inherently more complex.

Inventor’s new MBD tools, developed in partnership with Sigmetrix, are found under the ‘Annotate’ ribbon and give you a good set of tools that allow you to set-up datums, then work through the process of selecting the geometry and adding the appropriate GD&T information.

There’s a good amount of intelligence built into these tools, right from the off.

The system finds common groups and allows you to preselect geometry (for example, a pattern of similar holes) and the construction of the various elements is pretty straightforward, assuming you know what you’re doing.

Interestingly, the whole process builds quite intelligent models, so any design changes after the MBD elements have been added will be refl ected where possible — whether that’s changes to hole sizes, dimensions or datum changes. That information can then be shared using the Inventor parts or extracted downstream and placed into drawing views.

One thing worth noting is that at present, while Inventor supports exporting of this type of data to STEP AP 242, it doesn’t support reading of MBD-enabled design files from other vendors, whether that’s natively or using standard formats such as STEP or JT. Y

You can import the geometry, but the 3D annotations won’t currently show up.

Fig 5. Autodesk worked with Sigmetrix to add 3D annotation into Inventor 2018

In conclusion

Inventor is a functionally rich application and has been for some time. Whether you’re interested in traditional, prismatic modelling, looking to mix in a little surfacing or maybe even some subdivisional modelling use, then all of the tools are there.

More recent releases have seen this core set enhanced with some pretty nifty tools for topology optimisation and other technologies. Essentially, if you’re on subscription, you’ve already got a lot of bang for your buck but, at the same time, you’re going to want to see new capabilities added. Whether or not you actually use those tools remains to be seen — it’s just natural consumer behaviour.

But gauging the value of a subscription and the benefit you get from it comes down to two factors. Do I need my system kept up to date and do I want new tools that can make me either work more efficiently or work in new and exciting ways?

On both of these, Inventor represents some good value for money. The toolset is rich and mature, but the development is still finding areas that can be improved, workflows made less time consuming, more intelligent or robust and new efficiencies gained.

Then there is the addition of new tools that haven’t seen the light of day before.

The new MBD tools are going to appeal to a sub-set of Inventor’s user community, but for those that work in environments where MBD processes are becoming standard, this will be a huge benefi t and allow them to provide the information their customers desire or mandate.

The same can be said of the Inventor to Revit or IFC workflow that’s seen vast improvement in this release. Again, this reduces what might have previously been a convoluted workflow and makes it easier to generate the information that those in this environment are required to produce.

It won’t be for everyone, but for those that do require it, it’ll make life much easier and more efficient, allowing them to get on with developing those products rather than trying to wrangle the data into the correct format.

Ultimately, judgement of the value of subscription depends on your point of value, but if you’ve invested in Inventor so far, you’re unlikely to look elsewhere.

Although it might have lost a little of the spotlight to the newer, shinier and altogether different Fusion 360, it is still growing in capability that’s not only time proven, but its robust tools suit a wide spectrum of the engineering community.

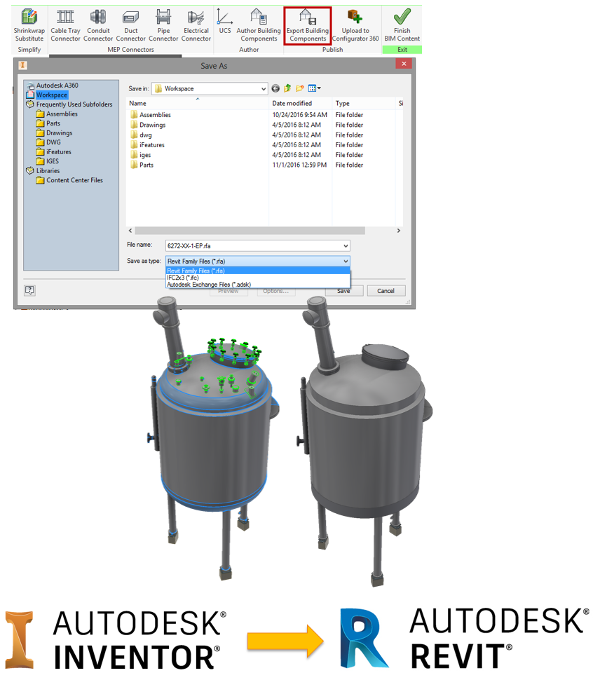

Inventor to Revit: 3D design & engineering meets BIM

While Inventor’s core user base is in the world of heavier engineering and design, it also crosses over into the world of its sister application suite, Revit.

For those that aren’t aware, Revit is Autodesk’s Building Information Modelling (BIM) tool and is used by thousands in the Architecture, Engineering and Construction (AEC) industry. This crossover occurs where organisations are developing products that eventually find their way into the built environment — whether that’s HVAC components, mobility solutions (elevators, escalators and the like) or down to architectural hardware or structural steel work.

The Revit world is currently undergoing a huge expansion of standardisation, driven by national and industry specified requirements for more rich descriptions of construction projects using increasingly intelligent tools than has traditionally been the case.

This 3D focussed working practice, referred to as Building Information Modelling (BIM) has meant that many working as suppliers or contractors to this industry need to provide richer descriptions of their products that can be readily inserted into Revit models.

If models can be supplied, it not only saves time in the process, but can also mean that specified products are installed more accurately, correctly and the whole process works more efficiently. And, of course, with a richer 3D description of a building or facilities, that same information can be reused downstream. Yes, the AEC industry has finally realised that what the mechanical engineering and design industry has been doing for 20 years makes sense.

With Autodesk’s leadership in the AEC market, both with AutoCAD and Revit, there’s huge cross pollination of use of these systems with Inventor and the transfer of data between the two has been a focal point in recent years.

The Inventor 2018 release sees this work continue in a number of areas and the whole makes for a quite slick workflow. As you’d imagine, most suppliers aren’t too keen (and there’s no real need) to provide complete CAD assemblies of components. As a result, the new workflow allows you to take advantage of Inventor’s shrink-wrap tools to ‘defeature’ a model and remove any unwanted details or components — combining them into single geometric ‘lump’ if needs be.

You then use the BIM Content Environment to defi ne MEP (Mechanical, Electrical or Plumbing) connectors that allow your model to connect up to the Revit model.

The UCS tool is then used to control the positioning of that product as well as other metadata required (referred to as Omniclass title and number). There’s also the potential to make use of Inventor’s built-in automation and parametric control tools (iLogic) combined with its Configure 306 cloud-based confi guration system here to add product families that are parametrically controlled.

The final step is to use the ‘Export Building Components’ tool to write out the data to either IFC models or RFA fi les native to Revit.

| Product | Inventor 2018 |

|---|---|

| Company name | Autodesk |

| Price | From £1,760 per year |