Ducati, an Italian motorcycle brand, was originally founded in 1926 to produce components for the emerging radio industry.

The 2013 Ducati Streetfighter 848

After the Second World War, this Bologna-based company began manufacturing engines and small motorcycles.

Today it delivers approximately 40,000 road and racing bikes annually, which are sold in more than 60 countries worldwide. These are grouped into six model families including Diavel, Hypermotard, Monster, Multistrada, Streetfighter and Superbike.

Of the 1,000 employees who work at Ducati, nearly 200 are involved in research and development (R&D).

The engineering staff includes approximately 90 people; 60 of those are dedicated to design. Also, Ducati has global operations and a wide network of partners and suppliers who handle 92 per cent of its production.

As any delay or mistake when transferring information can translate into longer cycle times and increased costs, the company has been actively pursuing tighter integration between all members of its product development teams.

In order to achieve this, it has implemented two solutions from Siemens PLM Software: NX, and Teamcenter.

“NX is the tool we use from the moment we start thinking about a new project up to its completion,” explains Piero Giusti, information technology manager for R&D at Ducati Motor Holding. “NX is used to design many different motorbike components, including the wheels, the chassis and the body, as well as custom parts – virtually everything except the engine.”

Hybrid approach

There are currently more than 50 NX workstations at Ducati. “The key benefits of NX are flexibility and ease of use,” comments Giusti.

“By ‘flexibility,’ I mean that it lets you generate 3D models with different methods, without constraining you to a fixed approach. NX with synchronous technology is a hybrid approach that avoids having to parameterise everything, so the user is free to choose how to achieve the final result.”

Ducati engineers use the NX 3D wiring functionality extensively. It allows them to verify cable routing inside the virtual assembly, minimising possible routing issues downstream.

“The next step will be the integration of the wiring diagram to eliminate the use of separate software, which inevitably causes problems with updating and referencing,” says Giusti.

“We have schematised the flow so that we can create wiring diagrams using the NX schematic functionality. After that, the diagram is passed on to the NX wiring application to incorporate all electrical information into the design. And finally, using the NX electrical routing solution, we prepare the documentation for cabling installation. NX lets us cover the entire process with an integrated approach.”

Secure data sharing

NX supports closer collaboration both within the internal development team as well as with external suppliers, who include companies that manufacture moulds and key components such as the fork.

Ducati expects to achieve even closer collaboration through the use of Teamcenter.

“We increasingly need to exchange model data with these suppliers,” explains Giusti. “With some of our long-term partners, we are investigating the possibility of providing them with direct access to the information in our system so that we can further reduce development time by having them work in parallel with our designers. Within a few years, we will integrate all of our strategic suppliers that produce technology on our behalf.”

Ducati has already begun this process with several of its suppliers.

Within Ducati, the use of Teamcenter is widespread with 250 workplaces that use this PLM solution to access information generated by the engineering department.

The company has also deployed Teamcenter at its Saima warehouse in Modena.

All motorcycles go through this site for some assembly operations, spare parts verification, or modifications due to mounting errors.

The warehouse staff has access to the information stored in Teamcenter through a dedicated line. They can view drawings, diagrams and assembly tables for all finished products.

The users at this site execute minor assembly operations, typically installing body parts and custom elements, but occasionally they perform more significant modifications as well. The users need access to product documentation.

“It is worth noting that it was easy for the Saima staff to learn to use Teamcenter. The fact that they had no specific training bears witness to the intuitiveness and ease of use of Teamcenter,” says Giusti.

“We couldn’t imagine working without Teamcenter. From our previous process that required tons of paper, we have eliminated paper and filing cabinets. Using Teamcenter we have implemented a digital information management system with traceable, role-based access, and a high degree of intrinsic security.”

Complex products faster

Ducati’s PLM solution has greatly accelerated the pace of product development, enabling the company to develop a new model much faster even though the use of electronics and related software has grown substantially.

Today’s motorbikes can have up to six or seven electronic control units (ECUs) for suspension, transmission, braking and stability. “All these systems are interacting and must be managed in an efficient and reliable way,” says Giusti.

“We now have product configuration handling requirements very similar to those of automotive or aerospace companies.”

In spite of greater product complexity, Ducati has cut one year off the development cycle for new motorbikes.

“Our design and development cycle has been reduced from an average 36 to 40 months to just 24 months,” he comments. “We are also able to update all existing models at annual intervals. It would be unthinkable to achieve such results using conventional design methods.”

Siemens PLM Software’s PLM suite has enabled Ducati to integrate all departments and operations: prototypes, production, warehouse, spare parts, and accessories. “By integrating and parallelising all these processes, we can now develop accessories concurrently with the motorbike,” says Giusti.

“In the past, it used to take 6 to 12 months before accessories were marketed. Now they are ready together with the bike, generating significant sales synergies.”

ducati.com

plm.automation.siemens.com .

//www.youtube.com/embed/QgqIWv5bhTA?rel=0

Focus on optimisation technology

During the technical development phase of Ducati motorcycles, the engineers carry out a number of simulation steps.

Performing these calculations from the earliest stages can ultimately lead to a quicker development time and improved quality of the final product.

“A wide range of structural, dynamic, fluid-dynamic and acoustics issues are handled through the intensive use of the most advanced finite element method (FEM), computational fluid dynamics (CFD) and model-based design (MBD) techniques,” explains Simone Di Piazza, Ducati’s CAE (computer-aided engineering) manager.

The open-architecture CAE solution Ducati uses as the foundation for this simulation-driven process is Altair HyperWorks, which includes modelling, analysis, visualisation and data management solutions for linear, nonlinear, structural optimisation, fluid-structure interaction and multi-body dynamics applications.

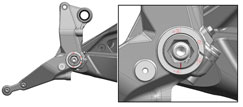

“As an example, Altair OptiStruct topology optimisation has become the Ducati standard procedure to improve the weight/stiffness ratio of our aluminum casted swing arms,” comments Di Piazza.

OptiStruct is a structural analysis solver for linear and non-linear structural problems under static and dynamic loadings. During this topology optimisation process, the engineers are aiming to create a structurally efficient part, in this case a swing arm, that has a high stiffness to weight ratio but still satisfies the stylistic constraints set out by the designers.

According to Di Piazza, the best results from topology optimisation are obtained when it is performed at the very beginning of a part’s development process.

“Other optimisation methodologies are chosen in the subsequent stages of the workflow. For instance, topography optimisation, to improve the design of the steel plates of our frames.”

“Although we currently only carry out optimisation in combination with linear-static subcases, we would like to extend this to a wider range of loading conditions.”

Of course Ducati is known for its high performance motorcycles and as such its engines and exhaust systems really form the heart of the design. In the development phase, the engineers work a great deal on the fluid dynamic and structural efficiency of these parts.

“In this field of application, a high performance finite element (FE) pre-processor like HyperMesh plays a key role in reducing the total simulation time needed to make an adequate number of virtual tests,” says Di Piazza.

“Additionally, a solid FE solver like Altair’s linear FE solver OptiStruct (formally RADIOSS linear) puts us in the condition to evaluate the acoustic performance of engine covers and mufflers. There is the obvious but challenging need to solve the trade-off between performance and noise levels, as best as we can.”

altair.com

Siemens software powers engineering performance at Ducati Motor

Default