AM simulation – This month Laurence Marks turns the spotlight on additive manufacturing, looking at the methods and challenges involved in simulating the process

Casting is a manufacturing process that is over 6,000 years old. In the early 1970s the first casting process simulation emerged, which made it possible for foundries to gain an insight into what is happening inside the mould during the process in terms of, for example, thermal stresses and distortion. But, with experience gained over several millennia, people were pretty good at casting before CAE even got into its stride.

Being a comparatively modern process, the techniques necessary for simulating additive manufacturing (AM) were established well before the technology had even taken off . That puts designers, analysts and, indeed, anyone in the design cycle, at a huge advantage.

As the AM process develops, we in turn develop our understanding of its physics and how it influences what we end up with in terms of product performance.

By working on the simulations and the processes hand in hand, it also means that the development of both is accelerated. Considering that you need to analyse what it is you’re actually making not what you wish you could make, this is of pretty high importance.

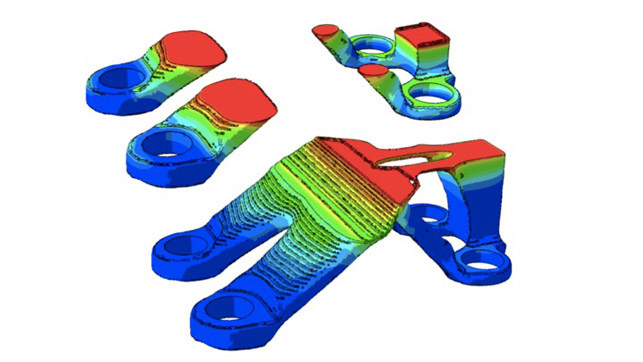

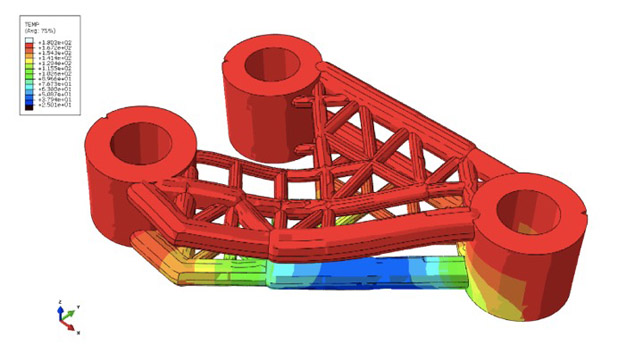

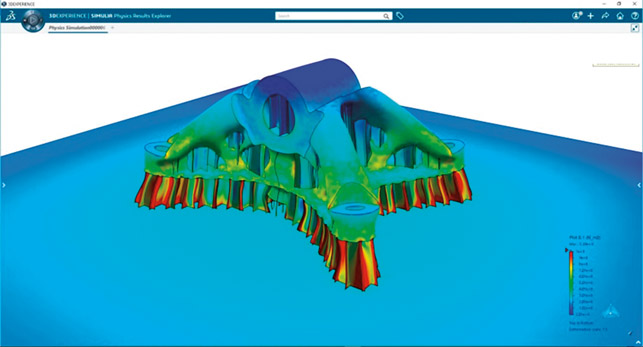

Many AM processes function by heating a material, sometimes moving it from one place to another, and then letting it cool down. Advanced FEA systems are really good at modelling what happens when you heat and cool material, and with a little imagination you can get material to appear where and when you want it to. In fact, intercept the command file that drives the printer and the simulation can use it to drive the material addition or sintering process.

Creating a basic AM simulation doesn’t require much in the way of new software if you start with the right basics in place. When the simulation runs, it provides an insight into what is happening to the part during a build.

The user can gain a good handle on deformation, internal stresses and, critically, what to do about them.

However, there is a catch. The reason for selecting a particular material for AM is that its properties change with temperature (or some other input).

For instance, heat up plastic and it will become softer and start to flow. That’s how we achieve the transformation from plastic wire to plastic Yoda, or from metal powder to a high performance gas turbine component.

But it’s not just the structural properties that change; things like thermal conductivity, heat capacity and thermal expansion are all temperature dependent. So, to start, you need a good handle on material properties and how they vary with temperature.

Matweb alone won’t get you far with that one. It takes some investment in testing but, as with all things simulation, the knowledge and understanding gained from the enhanced input data more than pays for itself.

To summarise, an AM simulation system has to model the following processes:

■ Heating of a local area

■ Addition of material locally (this may also be the transformation of powder to a solid)

■ Cooling

■ Solidification

■ Thermal expansion and contraction

Most of which, if not all, are established simulation procedures. By doing this you can get a handle on the following:

■ Shape of the finished component (which is sometimes distressingly unlike the designed shape)

■ Internal stresses in the finished component l Material properties of the finished component (although this one is very much a work in progress)

As with all things simulation, it’s not really about a one off analysis. Confirming that something doesn’t work is hardly a help in a high pressure situation. It does require a fair bit of investment but by running a series of simulations you will be able to vary production parameters, support strategies as well as analyse a whole host of other variables to see what might create a decent component.

So we can predict the shape of a manufactured component, the state of internal stresses and, in a few cases, with cutting edge software, have some idea of what’s been done to the material properties and microstructure (generally nothing good).

In a properly high performance application, we need to know all of these things as inputs to any simulation we do of the component’s performance in service. They are critical to ultimate strength and durability. As stated earlier, you need to analyse what you make not what you wish you could make.