Much of the aerospace industry got grounded during lockdown, but some companies used the time to prepare for a future uplift in the sector’s fortunes. At Airframe Designs, a key priority was updating the company’s simulation tools, as Steffan Evans reports

Travel restrictions triggered by Covid-19 have seen the number of air passengers fall to historic lows, placing airline operators and their suppliers under significant, sustained pressure. For some, however, it’s at least been an opportunity to rethink and reskill. A good case in point is Blackpool, UK-based Airframe Designs, which has used the lull of lockdown to engage in a re-evaluation of many of its design processes and development methods.

The company’s projects range from VIP galley upgrades and narrow-body aircraft seat design, to military projects such as Puma helicopter upgrades and design work for sixth-generation fighter aircraft.

Airframe Designs wanted to be able to offer clients more value from early concept through to critical design review; to upskill and invest in the engineering team as part of a AS9100 quality framework; and to become more agile in a tough, competitive market.

One potential area for improvement really stood out. The company had relied on several legacy FEA [finite element analysis] programmes for the past decade. An assessment of more up-to-date approaches brought to light many new platforms and toolsets that could improve simulation work.

That said, there were a number of requirements to bear in mind. The new toolset needed to support the industrystandard data format set by FEA solver MSC Nastran, used by most companies in the aerospace industry for regulatory compliance and to interact with other parties.

On top of that, it would have to be able to integrate well with Airframe Designs’ current workflow, be quick to learn, and deliver demonstrable time savings and efficiency gains.

Discussions with numerous CAE/FEA software vendors showed the Airframe team the significant advances in capability and deployment made by many different toolsets over the past decade. While many had elements that would work, they opted for MSC Apex, which they saw as a solution that is fast gathering pace in the sector.

Via initial contact at an aerospace industry event, Airframe Designs engaged Evotech CAE, a dedicated MSC Apex training provider, to help with its initial assessment and get its team up to speed.

Ready for take-off

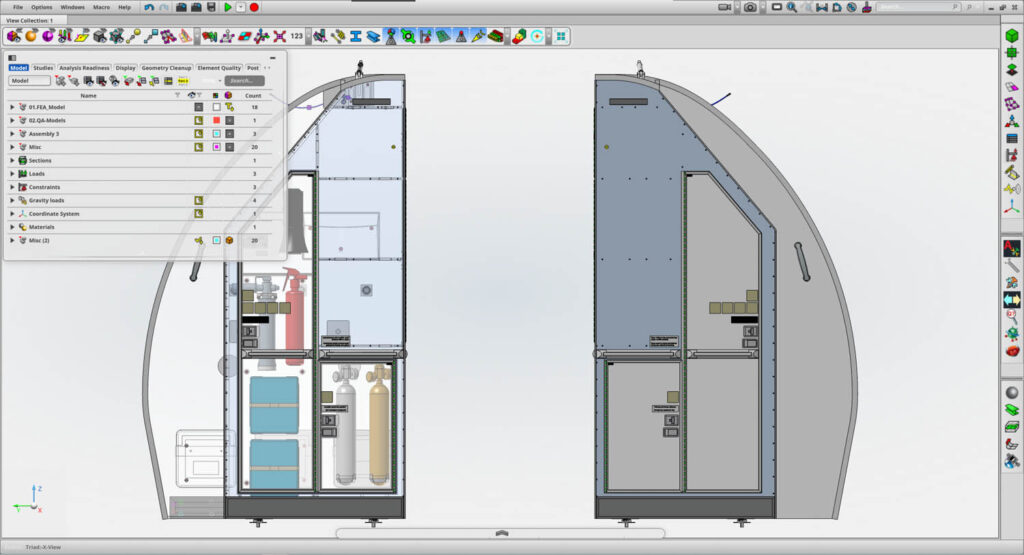

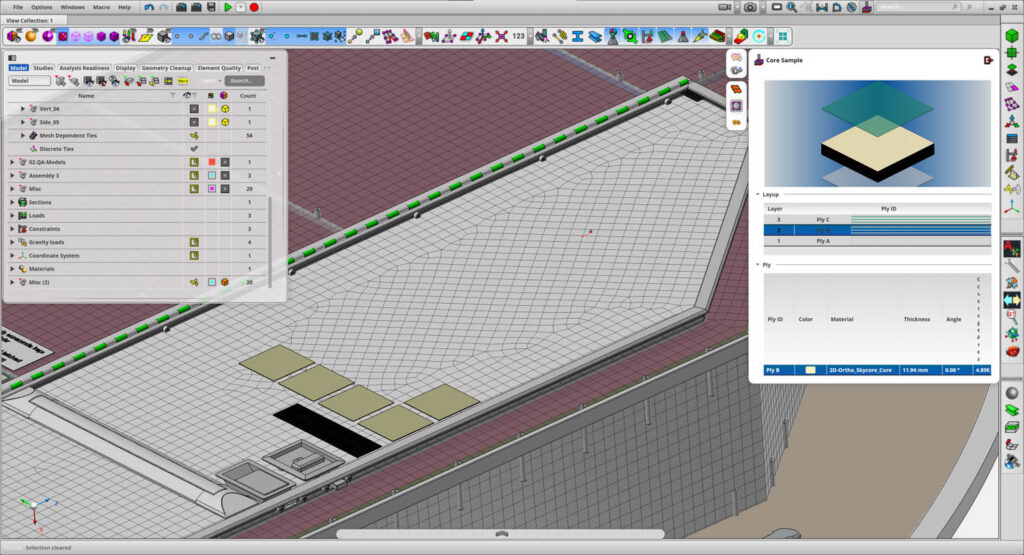

The initial project was a typical aircraft galley structure: a Boeing 737 stowage compartment, constructed of lightweight metallic and composite sub-structures, showing detailed joint definition and the appropriate loading.

In preparation, Airframe Designs’ engineers took an initial 12-hour online training course – enough for them to hit the ground running. In addition, they were also provided with a bespoke tuition programme, focusing specifically on the application of galley structure FEA.

A model of the aircraft stowage compartment was built, and the team needed to be able to incorporate three typical design updates, with the resultant model to then be prepared for external analysis in MSC Nastran.

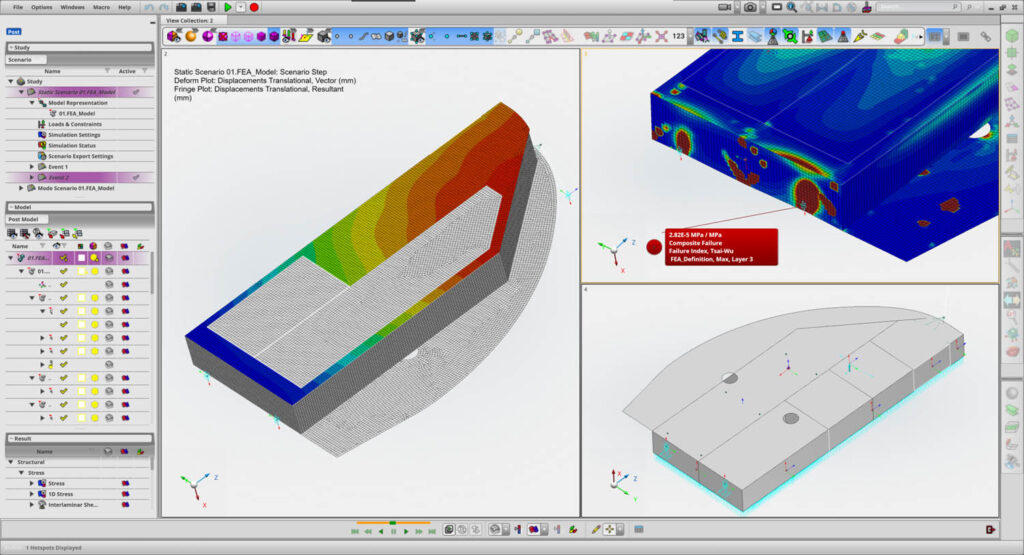

The resulting model development using MSC Apex proved to be significantly more efficient than that achieved when using Airframe Designs’ legacy toolsets. Given that the work had been performed by engineers with minimal product exposure, managers at the company were impressed that the turnaround took just a little over three days, compared to eight days or more with the previous software.

“Models developed in legacy software can be difficult to adapt or remodel, as a design evolves,” says Airframe Designs lead engineer Bill Thorne. “In Apex, simply modify the underlying CAD, and the model updates automatically.”

The time saved in such a project allows for effort to be focused on different areas of the design process, ensuring development goals can be met earlier and with reduced risk.

The next steps for Airframe Designs’ FEA development process will be to add more MSC Apex-specific Python training to the mix, in order that the team can incorporate a bespoke workflow for model build, verification and downstream post-processing, ultimately leading to more optimised structures, faster.