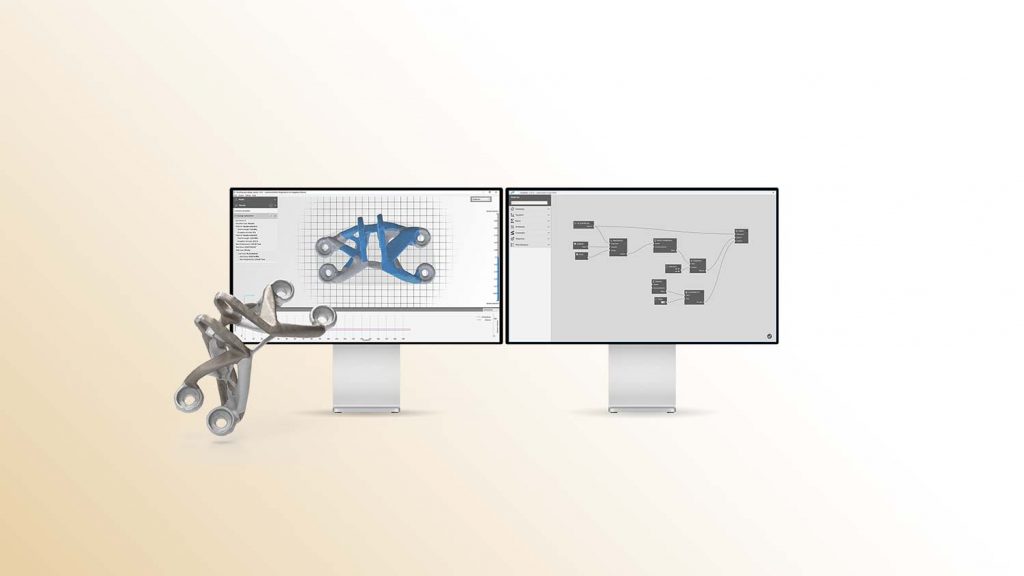

Additive Flow has launched the first release of its Formflow optimisation software, which promises to enable the production of multi-functional parts – pairing multi-physics with multi-objective algorithms and material science to deliver manufacturable parts.

With every production process having competing requirements – cost vs. quality, reliability vs. speed, and so on – Formflow aims to exactly specify the requirements required for local regions of parts, while optimising for specific business needs like cost and sustainability.

In its first software release, Formflow, aims to balance performance and cost savings with three key features:

- Accessible interface for powerful multi objective optimisation, letting users to switch optimisation goals and constraints

- Algorithms that allocate multiple material properties, via lattices, build-parameters, and materials, simultaneously with topology

- Multi-physics capability tightly coupled with as-printed material properties

“The engineers and businesses we’ve spoken with want to do better when it comes to harnessing innovation and sustainability, but are too often caught between their time limits, cost considerations and performance needs,” said Additive Flow CEO Alexander Pluke.

“Engineers have been calling out for a tool that can help them address these challenges, and we have had great feedback from our users on the new frontiers now available to them with Formflow’s capability.”

FormFlow enables users to create repeatable optimisation workflows that can be easily edited, retained, and shared amongst teams for maximum productivity and automation.

The software allows users to specify the exact requirements needed in specific regions of parts, while optimising them for specific business needs, like cost and sustainability.

Additive Flow’s proprietary algorithms are capable of optimising multi-functional parts by integrating multiple physics (thermal, frequency, structural) within a coupled optimisation loop, allowing the allocation of material properties to address the needs of a part.

Material properties can be tailored to meet competing functions within a part, based on assigning multiple lattices, build parameters, or materials, in conjunction with topology – depending on the technology and material requirements.

Additive Flow CTO Charles Fried explained that the team had built its solvers from the ground up, to be ‘both highly computationally efficient and achieve the demanding goals of our customers’.

“This means compelling performance and robust accuracy against benchmark results,” he added.

Pluke concludes, “We recognise the impact our software can have on businesses’ KPIs, such as cost saving and time to market, but what really drives Additive Flow as an organisation is empowering our users to achieve what they want.

Pluke concludes, “We recognise the impact our software can have on businesses’ KPIs, such as cost saving and time to market, but what really drives Additive Flow as an organisation is empowering our users to achieve what they want.

Additive Flow is launching with a time limited offer for SME organisations to secure their first year license at a launch price of £500, for the first 500 sign ups.

Additive Flow featured in the 2020 D3D 30 list of the technologies from around the world that could boost your workflow – read more here.