Cloud-native CAM tools have finally arrived at Onshape. Stephen Holmes gets an early look at the offering, an easy-to-use toolset backed up by serious speed that will delight current users and perhaps turn the heads of newcomers

It is almost a decade since Onshape broke cover, bringing CAD tools to the browser. Since then, the product set has evolved steadily. While the CAD customer base hasn’t completely shifted over to fully cloud-based CAD just yet, Onshape’s arrival and subsequent acquisition by PTC in 2019 signalled a fundamental change to the market that has prompted other CAD vendors to slowly shuffle in the direction of web-hosted applications.

Onshape is loved by both those companies that depend on it (from start-ups, SMEs and educational institutions, and increasingly a number of bigger names – like Trek and Formlabs) through to global corporates that use it as a secondary CAD system – primarily for its ease of access, low hardware requirements and increasingly weighty toolset.

So when we heard that cloud-based CAM tools were finally about to be launched by Onshape, we were keen to find out more.

Onshape Cam Studio is included as part of its Professional and Enterprise subscriptions, loading immediately (with everything on the browser) and ready for use as part of a per-user, per-year licence that generally starts at around $2,500.

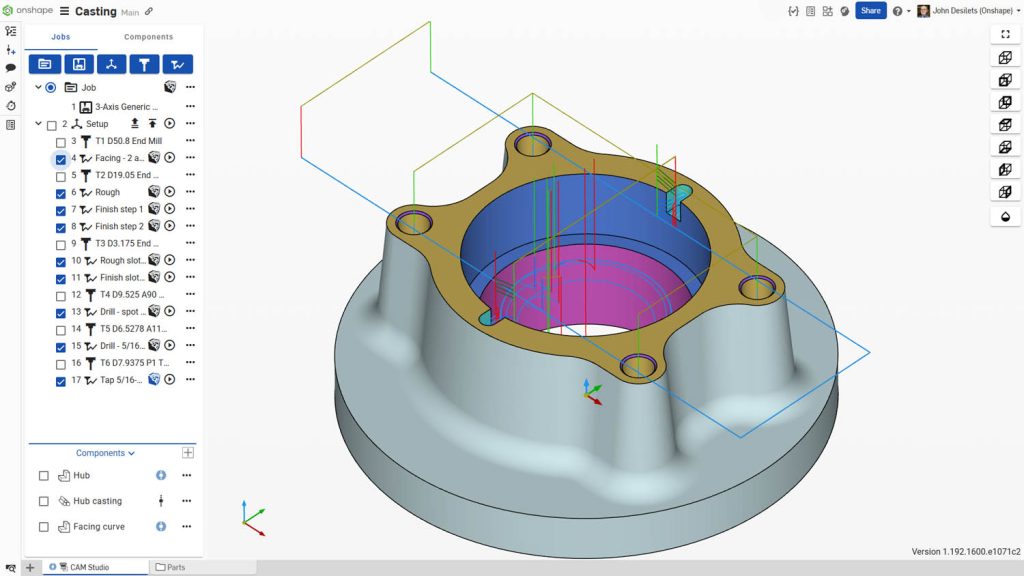

In a nutshell, Onshape CAM Studio offers 2.5- and 3-axis machining, integrated tool and machine libraries, mill-turn operations and machine verification

In a nutshell, CAM Studio offers 2.5- and 3-axis machining, integrated tool and machine libraries, realtime simulation and – an eye-catching feature for a CAM software at this price point – machine verification.

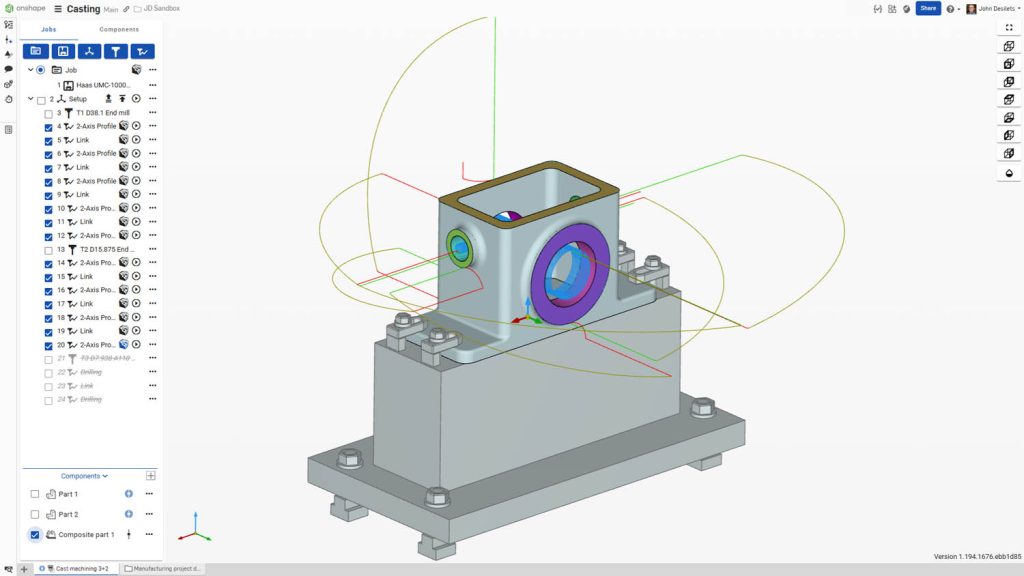

Advanced features like 4- and 5-axis machining, millturn operations and adaptive roughing will become available in a future CAM Studio Advanced offering – more of which later.

First cut

CAM functionality is straightforward: you start a new part or assembly in Onshape, create a new tab for CAM functionality and you’re straight into preparing a part for machining.

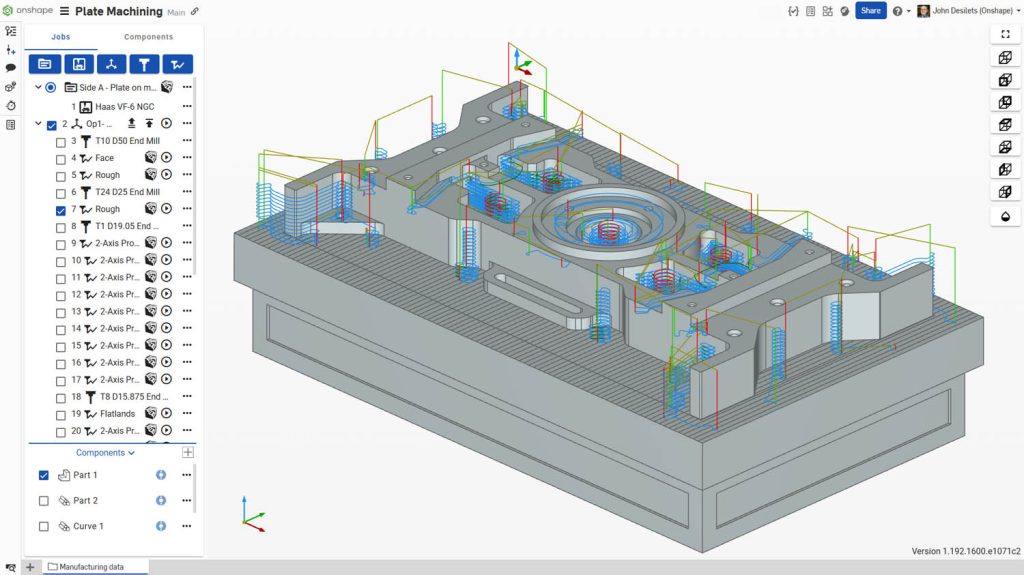

Once you’ve selected the part you want to machine, set-up is as simple as selecting the appropriate options from the columns. Pick the machine you want to run the process on from the list (which as a cloud software, will continue to update and grow); generate your set-up from a breadth of options that include orientation, stock definition and tool choice; and then pick a toolpath, before verifying it with toolpath simulation. There are lots of different controls that allow the toolpath to be shaped in different ways and directions, as well as other strategies.

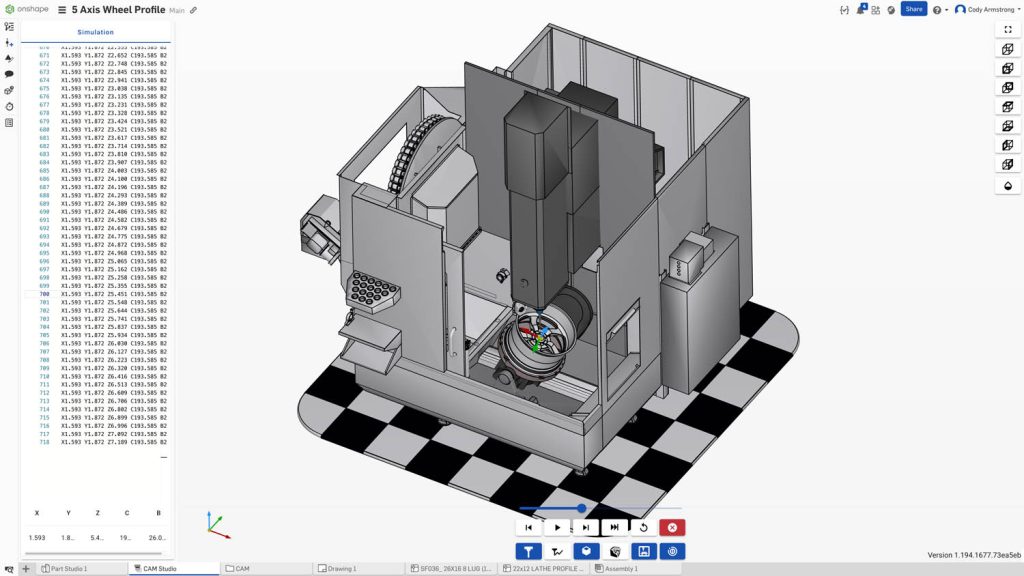

A final level of testing based on full-blown machine simulation helps you to understand how the process is going to interact with your machine and not just the stock and the tool, identifying any collisions.

The next step consists of post-processing the universal code and translating it into G-code for your specific CNC machine. There’s also the option for rest machining, allowing the software to simulate all necessary passing operations with different tools – from rough through finishing – in order to speed up the simulation of the full process.

The workflow is undeniably slick. From Onshape CAD model to generated G-code heading to your 3-axis CNC machine, it’s a seamless process. As you’d expect, there are plenty of options to customise tool libraries, machines and post-processors to best represent the kit with which you’re working, making things go even more smoothly.

Onshape says that CAM Studio Advanced will target higher-end CNC jobs, for faster, more precise machining. It will do that by supporting 4 axis, 3+2 axis and 5 axis machining and, down the line, providing advanced mill and turning capabilities.

While there was no pricing for CAM Studio Advanced at the time of demo, the out-of-the-box capabilities here look on par with those of leading competitors.

What’s particularly impressive is the speed with which big assemblies, like computationally intensive 5-axis toolpaths, can be simulated in Onshape CAM Studio.

We’re talking hundreds of thousands of lines of toolpath code, plus the whole machine simulated quickly and smoothly in seconds, with any collisions highlighted, ready for adjustments to be made.

The more complicated and detailed the features that the user is defining to be machined, the bigger the benefits a cloud-based system will provide over a locally installed system.

It also helps that on machine shop floors, nobody is running a super-expensive workstation, so being able to do all of this on a basic laptop via a web browser is an additional benefit and enables users to invest the savings they make in new CNC equipment.

Another big win for the cloud is clear when it comes to sharing manufacturing data. Knowing that you’re using the latest designs when collaborating with team members and external stakeholders has always been a big feature of Onshape’s CAD product.

With CAM Studio, this now runs straight through into manufacturing, allowing early identification and resolution of production issues. Designers can securely share models as simply as sharing a URL and swiftly revoke access should suppliers or orders change.

While nagging fears persist in some corners about the security of cloud-based software, never handing over a file and controlling permissions at will means you have total control over your design.

Onshape executives are also keen to point out the company’s built-in PDM tools, which mean CAM strategies can be versioned alongside CAD models.

Conclusion

The launch of Onshape Cam Studio will no doubt spark debates around which native CAD-CAM set-up works most proficiently and provides the best value, given that most vendors now off er a cloud-enabled offering.

Autodesk Fusion has built a solid following, thanks to CAM tools that also benefit from cloud-based acceleration for toolpath simulation. Solidworks 2025 has added Delmia Shop Floor Programmer with cloud connectivity, which includes 3-axis milling, wire EDM, and scalable upgrades for enhanced functionality. Siemens has shifted NX’s capabilities to the cloud, giving the ability to add on CAM tools to NX X when needed, SaaS-style.

It’s a crowded field, and that’s before you consider the offerings of the major CAM specialists, and what the likes of CloudNC, Toolpath and others are doing with AI to generate optimised toolpaths.

AI is something Onshape is already looking into on a broader level, way beyond just CAM. But being cloud-native, it should have several advantages over traditional software. Onshape executives have told us that the rate of updates and improvements to CAM Studio is set to be quick, in the same way as the company’s CAD product has evolved over the years, but don’t expect AI assistance too soon.

Overall, there’s something intriguing about what Onshape is doing with CAM Studio. Its initial successes are likely to be made with existing Professional or Enterprise users, by off ering the tools directly through their familiar workspaces, enabling them to run CAM operations up to a certain point without needing third-party software.

Depending on where the price of the Advanced offering lands, it could also make Onshape a more attractive package to those running more serious CNC equipment.

The speed of Onshape’s cloud processing power for complex work makes it worthy of a benchmarking exercise at least.

A big part of Onshape’s early appeal was its ability to help design teams collaborate. Today, it has expanded to connect engineers, manufacturers and external suppliers all in the same chain and all with the least amount of fuss. CAM adds another string to this bow, and on first glance, it has the potential to fly.

Pricing: Onshape CAM Studio is included with Professional ($2,500 per user, per year) and Enterprise licenses for Onshape. Onshape CAM Studio Advanced – $TBC

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here