The last few years have seen a multitude of online part provision services come on stream. These are typically split into two camps. The first is the offering of in-house manufacturing capabilities using digital services to provide communication and quotation for potential customers.

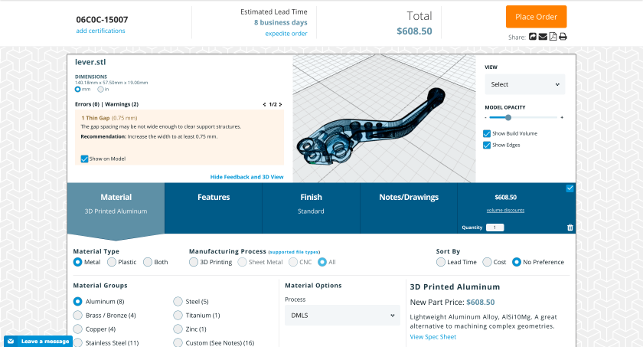

Xometry, which works in the browser but also has a plug-in available for SolidWorks, will find any errors in your part that are incompatible with your selected build process or material

Protolabs are probably the best known and perhaps have the widest spread of capabilities on the market. Then you have the ‘hub’ model which uses a single resource to provide access to a range of service providers but all run through a single interface. There are numerous of those out there, particularly in the 3D printing and additive manufacturing services space, look to 3D Hubs as an example.

Then you have an organisation like Xometry. The company has hit the headlines in recent months due to its huge investment (up to $23 million at the latest count) from a wide range of household names (General Electric being perhaps the best known).

Xometry combine the two models into a single offering. It has some in-house manufacturing resources (currently covering CNC and additive manufacturing) but its primary focus is to build a network of manufacturing partners to expand out its reach and capabilities — as well as to increase its capacity.

So shall we explore what the service offers and what we can learn from the experience? To do that, we’re going to start with the quotation process.

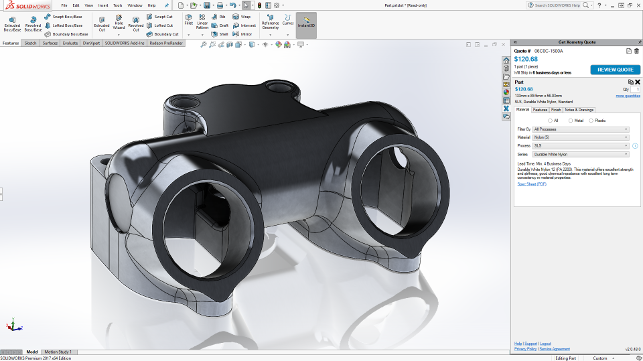

The Xometry addin for SolidWorks gives you live feedback for production costs for the part on screen

Getting a quote

Xometry is, as you might expect, focussed on a web-based quotation service. Once you’ve registered for the service, you can start to upload your geometry files and start to build up quotes.

While for 3D printing, you’re most likely to want to choose STL as a means of communication, it’s worth noting that because Xometry offers much more, it’s often the case that you’ll need a nontesselated file of your part handy as well.

Xometry supports a range of formats including several native file formats (such as SolidWorks, Catia, Inventor) as well as the usual array of standard and neutral formats (such as STEP, IGES, Parasolid, ACIS etc.).

If you’re a SolidWorks user (running 2017 onwards), then there’s also a plug-in that sits inside your property manager and gives you access to quotes directly from the SolidWorks UI. Whichever route you take, the end result is the same.

Once your part is uploaded to the quote, you’re then able to start to fine tune the process and material you want to build.

Xometry offers a best-guess based on the geometry of your part and as you start to filter down your material or process options, the price updates accordingly.

Whether you lead with a material choice or select a process will depend on your own preferences. As a best guess, most folks know what they want in the first place, so selecting the process, then the material makes sense — but this is by no means a forced decision. In fact, it’s ideal for experimentation.

Once the process and material are chosen, you can then start to defi ne any post processing options. Again, these vary from material/process and include all manner of standard fi nishing techniques from bead and sand blasting to anodising or powder coating.

At this point, you’ll also start to notice that the quote is building up. Perhaps the final selection is the number of parts you want.

What’s interesting here, even before you get to ordering the parts, is that Xometry’s services shows the disparity of economies of scale between most additive processes and CNC processes.

One of our test parts is a Ducati brake lever that we had additively manufactured. While the one-off cost was around the $600 mark, adding multiples to this only saw the price drop by around 50%.

Conversely, another of our test parts (a smaller hex nut shaped ring component with some tricky internal cavities) was CNC machined from aluminium. While the one-off cost was around the $120 mark, subsequent multiples saw that price drop dramatically.

Why the difference? The reality is that once the hard bit (the programming and machine set-up) is done, it’s pretty simple to repeat the process.

There’s a range of feedback that’s available at the quotation stage. If the system fi nds any issues with the parts (according to the process you’ve selected), it’ll flag them up. If you need more complex features (particularly when dealing with CNC components) such as threading etc. or there are more exacting requirements in terms of tolerances or surface finish, it’s also possible to upload technical drawings alongside your geometry files.

You pay for your parts and the next thing that happens (from the customer’s perspective) is the parts arrive through your door within the allotted delivery schedule.

A.I. & the RFQ

What’s perhaps most intriguing about Xometry’s offering is not the breadth of services they offer (which are pretty rich and deep) but rather the part that’s hidden almost entirely from the customer.

While Xometry has capabilities in-house, its primary role is to work with a wide range of partners that have spare capacity on their own machine tools and capabilities.

When you place your order, the algorithms look at the part and works out a price for you based on previous history. What then happens, in the background, is that work is offered up to a suitable partner within the network. The partners then accept or reject it, if it’s the former, the work is done and sent to you (sometimes directly, sometimes via Xometry’s logistics hub).

Here’s where things get interesting. Xometry’s platform is constantly learning about how to quote for work more accurately. It might adjust it upwards or downwards, with the goal being to offer the most competitive price for your job.

What that means is fascinating. In the instance that the algorithm gets it wrong and quotes too low meaning none of the partners accept it, it’ll accept the work, pay a premium to the partner (effectively making a loss) and you still get your parts. But next time around, the system has learned from its miscalculation and adjusts the quotation process accordingly.

Two of our test parts from Xometry. The rocker box cover in SLS nylon and the Ducati brake lever in DMLS aluminium

In conclusion

Xometry has come from nowhere in the last couple of years to doing some serious business in the manufacturing sector. At present, it is focussed on the North American region and while the company has no immediate plans to branch out further, I would imagine that’s on its to-do-list.

For those looking to procure parts, the end result is that you are immediately presented with a range of options than span a diverse range of capabilities and processes.

At present, Xometry offers a variety of additive processes (including FDM, SLS, DMLS, SLA/PolyJet), CNC machining, casting and sheet metal. The materials available vary depending on the process you select, but again, cover the most common you’d expect.

Ultimately, your selection of whether to use Xometry’s services depends on price and competitiveness — as well as, I suspect, convenience. If the price is good, the process is simple, ready to go and fully traceable. It comes down to competitiveness of the price and the ease of the whole process.

But alongside the pure commercial, service provision aspects, Xometry also represents something else that’s truly fascinating.

There’s a lot of talk about machine learning in the manufacturing space, but other than the odd bit of topology optimisation and some talk about artificial intelligence driving 3D printing, there’s very little in terms of actual solid examples as yet. When you distill what it is that Xometry does, it becomes fascinating from a technology point of view. Why?

It’s using its own algorithms to quote for work, based on geometry and part requirements. What’s interesting is that this is being done with a serious amount of human effort on the back end of it.

Once you hit that order for a CNC’ed part, the job is sent to a job shop that has spare capacity and experience with that type of job based on previous work. They do the programming work, machining or sintering (or whatever), finish the parts, package them up and send them back to you. You get your parts, they get paid — 15 days later.

For the customer, that means a transparent and efficient quoting and ordering process. No sending out RFQs and waiting a week for a response. Submit the order, pay for it, parts ship. Done.

For the machine shop on the other end, they don’t have to waste time filling out RFQs, quoting for jobs. They bid on the work, get the work, do the work, get paid. The business is nationwide — so these smaller manufacturers are gaining work outside of their own localised area and outside their particular specialisation. Of course, Xometry gets its cut of the action, but that’s how it makes its revenue.

There’s also a lot of talk around at the moment about how machine intelligence and automation is going to remove manufacturing jobs. Personally speaking, I’m dubious.

Manufacturing isn’t something that can be replaced with robots quite as easily as the media thinks. It’ll always require human intervention.

But perhaps those doing the hard work of manufacturing parts can take advantage of machine intelligence and learning, keep their machines humming, filling up spare capacity, remove downtime and some of the drudgery of paper work.

Xometry’s success will ultimately rely on its ability to compete in an increasingly competitive manufacturing landscape, but it’s pushing the boundaries of what tech can do as well as keeping manufacturers in business.