The hope is that Whippet Bicycle will appeal to anyone who loves cycling and appreciates good design, whether young or old, male or female

Inventions of the first bicycle emerged in the mid 1800’s and despite being surpassed by faster and less labour intensive means of transportation, the bicycle is arguably more popular than ever. Most of us had one from a very early age and probably still have one, or a few, now. Why do we covet them so? As a means of getting around, yes, but as objects what’s the fascination?

For designer and engineer Graham Powell it’s that they offer a perfect mix of form and function. “Part of it is just the joy of engineering because you can see immediately what it does,” he says. “But you also form an emotional connection far beyond merely being a purely functional item – they almost become part of the family and often cyclists will have more than one, but couldn’t part with an old one. That emotional attachment – not many machines have that.”

Powell admits to being a life long cycle enthusiast and for the past four years he’s put a lot of work into designing, developing, building, refining and test riding his own bicycle. Called Whippet Bicycle it’s a folding design that doesn’t actually fold, it retracts.

A classic diamond frame with a difference, Whippet utilises twin oval tube arrangements that offer ‘controlled flex’ to absorb road shock. This allows for a comfortable ride despite its 20-inch wheels. And, when you’re done riding and once it’s been retracted, Whippet can be easily rolled along on its rear wheel.

“It does ride really well and for me that was as important as folding,” admits Powell. “You can, and I have, ridden it for 40-50 miles and it’s pretty comfortable and that is due to the twin tubes that you can just about flex with your hands.

This of course means that you don’t need a suspension system, which small wheelers tend to have to make them more acceptable in offering a less bumpy ride.” This is, of course, the Whippet Bicycle now after its four year journey, a journey that began in March 2013 at DEVELOP3D LIVE. Powell, who at the time was working as the Post Graduate programme director of Product Design at the Birmingham Institute of Art & Design, was attending our annual event at Warwick Arts Centre on a work trip research day.

The next day feeling inspired by both the talks he attended as well as a meet-up at the event with Mark Sanders (the inventor of the Strida folding bicycle), he was day dreaming about bicycle design during a coffee break. He started playing around with some items on his desk – namely CDs and wooden coffee stirrers. By his own admission, Powell likes to challenge the rules and was thinking ‘does a folding bike actually need to fold or is there perhaps another way?’

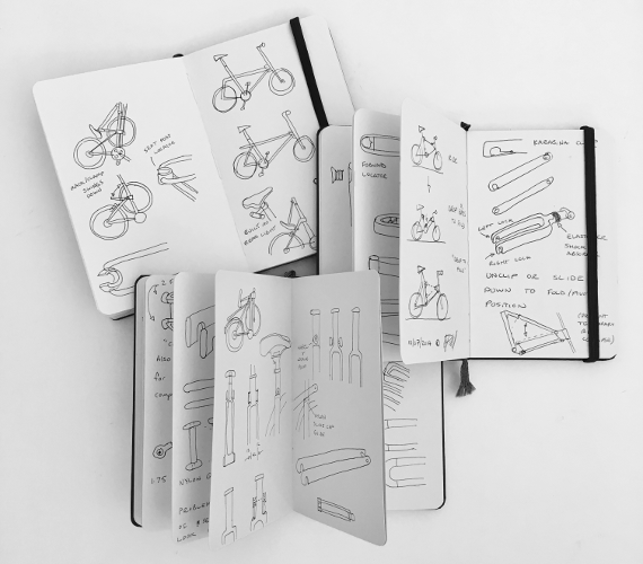

The bicycle was only modelled in SolidWorks halfway through the project

“Looking back, playing in 2D on the table heavily influenced the retractive solution I came up with for the bicycle. It’s quite obvious when you think about it, it is very 2D,” says Powell. He then got out his sketchbooks (and purchased a few more) to sketch out his ideas. Of course, he was indulging his own love of bicycles and attempting to discover whether he could indeed design a viable alternative to the traditional folding bicycle, but even at this early stage he did have a style of bicycle in mind and a user it might appeal to.

The style – clean, minimal and modern – was also influenced by designhunter.co.uk, a luxury lifestyle website that Powell’s wife Helen, an interiors writer and stylist, founded in 2009. “At the forefront of my mind and his, as I was going alongside him on this journey, was who is this bicycle for? It wasn’t like ‘let’s design a bike and then see who might want one’,” she recalls.

As Powell explains, the target audience could potentially be anyone who loves cycling and appreciates good design, whether young or old, male or female. Offering a slim storage solution means that it may also appeal more to the urban dweller where space and security is a priority.

Bicycle research

Before getting any further into the design process Powell decided to carry out research and immerse himself in all things bicycles from reading the relatively modern history of folding bicycles – particularly Pederson, Moulton, Brompton and Strida – to checking through thousands of patent abridgements, some that go as far back as 150 years.

Where the inspiration began — during a coffee break playing around with CDs and coffee stirrers

Whilst working on Obsessionistas, a website about collecting he’d set up a few years previous, he’d met an engineer and historian Andrew Millward, who has over 360 Edwardian bicycles and was involved in setting up the National Cycle Archive at Warwick University. He provided Powell with the patent abridgements from the 1860s to the 1900s and then Powell went to the university to look through the rest up to the 1920s.

“He is a true historian of vintage cycles and told me that 25 per cent of patents in the late 1800s were bicycle or tricycle related because that was the innovation at the time.

“The patents were amazing to look through and it makes you think that people are claiming something is new now but here it is in 1882, just not in carbon fibre,” says Powell.

Graham Powell then filled many sketchbooks with his folding bicycle idea

Full of theory, research and practical ideas, in Summer 2013 Powell successfully applied for a grant from Innovate UK, resigned from his teaching job and set up a workshop in rural Warwickshire close to Leamington Spa.

With 18 months of funding secured, he bought a small lathe and milling machine to set up what he refers to as a “lean workshop with an old school approach” in that it involved technical drawings and hands on making.

Facing up to challenges

A folding, or retracting bicycle in this case, is a complex product that poses many technical challenges and the first crisis occurred a year down the line from his original idea.

The angled top bar on his first prototype, which he’d built from wood, plastic and aluminium, had always proven troublesome and the solution he arrived at was to simply remove it and lift up what were the middle twin tubes.

“The sloping third top bar was a nightmare, just too many joints and pivots that would require complex engineering like hydraulics to make it work, and that wouldn’t suit the bicycle,” admits Powell.

“The answer was obvious of course once I saw it – it was to just get rid of it. Ironically this is what I originally did with the coffee sticks but I went straight to idea number two thinking that was the solution.”

He reworked this from what he calls ‘Metal Bike One’, which was a fully working prototype that he machined from 6061 aluminium. “It weighed a tonne,” he laughs,“but I still managed to take it out for test rides.”

For his next prototype he used custom rolled T45 steel tube for the frame from ProFormance Metals in Daventry.

Slim and retractive, Whippet Bicycle is just 190mm wide in its folded mode

It was at this stage that he then enlisted the help of a sub contractor to model the bicycle up in CAD to create a full set of fi les with accurate dimensions, geometry and details for machining and manufacture, including laser cutting and 3D printing. “As the design was taking shape in SolidWorks, I have to confess to having been a bit of a ‘back seat driver’,” smiles Powell.

At this stage, Powell also had a few small concept parts 3D printed by AME Group for testing including curved washers and tube end caps, which were proving challenging to machine himself.

He commuted around 1,000 miles on this prototype, but did it in stealth mode as it had to be fitted with a special full fabric ‘IP jacket’ to keep prying eyes from spotting its secret design before the patent was filed.

“It didn’t look great but it was solid and it reassured me that the whole twisty, lateral stiffness thing was totally resolvable although it was slightly over engineered.”

Keeping the faith

It was whilst working on the third prototype that the second major crisis struck. This time it was the front locks and after reviewing his early sketchbook ideas, he redesigned them again, but not without a lot of hard work.

“This was probably the hardest part of the project. With the retraction design the locks are key, and with the front wheel tucking up through the middle they have to tighten up fully, be fail-safe and accommodate longer term wear and potential abuse,” explains Powell.

Challenges like this can really test your resolve especially when working long hours on your own in the dead of winter in a cold workshop. As Powell admits, often the hardest part of this project was keeping the faith. You have to embrace risks and failures whilst also adopting the designer-maker’s mantra, which he describes as, “make it, make mistakes, make it work, make it again, make it good, make it again, make it even better.”

‘Metal Bike One’ was the first fully working prototype, which Powell machined from 6061 aluminium

With prototype four the design was definitely taking shape and after the careful machining and hand filing (which Powell says he dedicated many an hour to), these parts together with new lighter weight oval 25CrMo4 frame tubes, commissioned from Columbus Tubing, were joined together by local master brazer Lee Cooper.

Following extensive test rides and folding, Powell further refined the design into bicycle number five with new details, materials, aesthetics and, what he refers to as, “engineering jewelry” (in other words, those shiny aluminium components and widgets that bicycle enthusiasts love).

It was in the gearing up for launch that Powell’s wife Helen became very much involved in the project, lending her skills in styling, photography and branding as they worked together on digital marketing and website design.

Graham Powell in his Warwickshire workshop where he spent many hours hand building components for the various Whippet Bicycle prototypes

First public outing

In April 2017 it was time for the big reveal and the location they chose in which to do this was Bespoked 2017, the UK hand built bicycle show, located in Brunel’s Old Station and Engine Shed in Bristol.

“We always wanted to launch Whippet Bicycle at Bespoked where fellow cycle enthusiasts of all persuasions would be able to give us valuable and honest feedback about our new design. We were expecting a lot of criticism but received largely positive comments, and many from Brompton and Moulton owners, which was a real surprise.”

As an added pat on the back for all the hard work, Whippet was awarded a Technical Excellence Award from the event organisers.

Although buoyed by this reception, and rightly so, Powell realises that it’s still early days and the next phase is working on an appropriate route into production and also to get an additional pair of engineering hands onboard. “I see myself more as a designer rather than an engineer and the bike needs to be drawn up in CAD again and fully FEA analysed. I have all the standards and have intentionally over engineered it so it could be lightened and refined as we learn more.”

Whippet Bicycle has certainly been on one hell of a ride so far and it’s not over yet…

Whippet Bicycle offers a new take on the folding urban commuter

Default