Siemens NX – Siemens has moved its flagship NX product to a continuous release schedule, promising smaller, more manageable updates. We explain what that means for users and take a look at what’s new in the latest of these updates

Throughout its decades long development history, Siemens NX has been delivered to customers in the form of a major annual release, followed by a series of smaller service packs throughout the year. That is all changing. From now on, the development team behind this product will be taking a more continuous approach to delivery. So, what does this mean for customers?

Essentially, it means a regular stream of monthly updates, as seen with more recently developed cloud-based systems, such as Onshape or Autodesk’s Fusion 360.

The benefits of this approach are said to be numerous; among them is the reduced impact of each update, in terms of fewer installation problems and less training/learning needed for users.

At the same time, Siemens has taken the opportunity to address a key issue affecting its software updates: close coupling between NX and Teamcenter. This has been tackled, so that users don’t need to upgrade both packages at the same time (important, when you consider that Teamcenter upgrades can be huge undertakings.)

It’s also worth noting that Siemens will be removing release numbers from the product name, for example NX 11 or NX 12, so it becomes simply ‘NX’, with no release identifier. This may cause some confusion for those users working in a supply chain or with colleagues based across multiple sites who perhaps update their software at different times.

However, a build reference will still be provided for ‘major’ updates to the system, with monthly releases rolled out between major updates and 100% compatibility within these releases. A key NX strength has always been its ability to open legacy data no matter how old, and that won’t change with continuous release.

Siemens NX is most commonly found in large enterprises, where installations have tended to be heavily managed in terms of software updates, roll-outs and training. Attend any major vendor conference and you’ll typically find that many customers are two or more major releases out of date. That’s because upgrades are often perceived as a big upheaval in terms of best practice and established processes.

That said, the level of change is optional, with you (or rather, your company) able to decide upfront how to deal with NX updates.

You can have the system download and install them automatically, although it still does require human interaction to initiate an update even after being enabled by admin. If you want greater control, you can have that, too – useful for stopping those two young punks in the corner from ‘going rogue’ and updating software independently. Or, if you want to stick to an existing internal best practice, that is also an option.

Siemens NX – Machine-taught UI

Moving on to the content of upgrades, a recent big-ticket item has been the introduction of an adaptive user interface (UI). How an individual user interacts with NX has always been an issue for the system, because it’s built for a wide variety of users and workflows.

In recent years, the development team has introduced a number of tools that allow the system to be configured for different user types (industrial designers, engineers or machinists, for example); industry sectors (such as automotive, aerospace or consumer goods); and processes (such as tool and die making).

In the latest update, this configurability has been given a rather spectacular makeover.

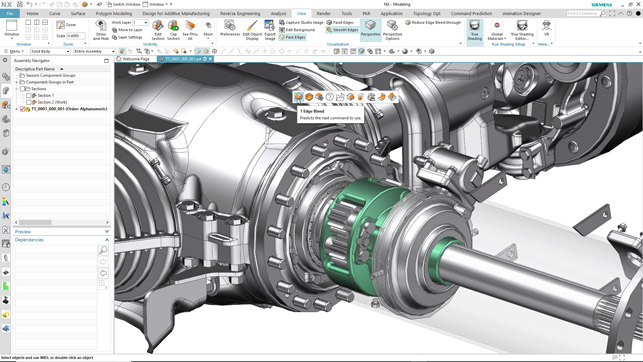

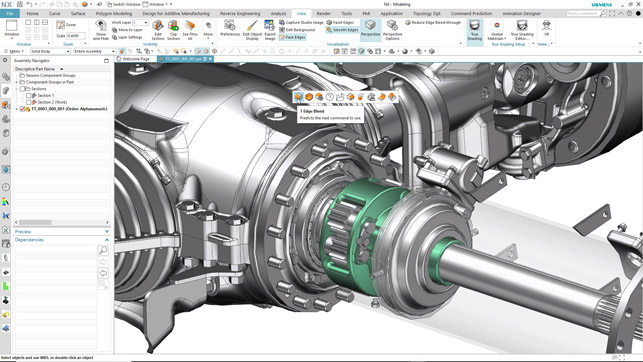

The nature of design and engineering work means that the operations that an individual user performs in NX are likely to be pretty repetitive over time. What Siemens has introduced is a new module that learns from an individual’s use of the system and ‘guesses’ which ten commands they are likely to need next, based on their most recent command.

These ten ‘next steps’ are presented in a toolbar that is either situated to the left of the UI (next to the navigator tool) or can be torn off and used in the modelling window.

This tool is built into all of NX’s application areas, moreover – part modelling, assembly building, FEA, CAM and beyond.

While the system learns an individual’s patterns of use, it cannot at present aggregate this learning across a whole workgroup. What it can do, however, is take learnt suggestions from one user and transfer them to another, which might be useful for building up informal best practice.

On the flipside, however, it might also perpetuate less desirable practices across teams of users.

As a first release, it’s clear there’s huge potential here. Yes, it might not be that useful for general tasks – but as you get into more specific workflows and toolsets (think sheet metal, for example), it could prove really valuable. If I have one criticism, it’s that the presentation of commands could do with a bit of work. Making commands available at the cursor would make much more sense, reducing both mouse and eye movement, so the user can focus instead on the task at hand.

Siemens NX – Design efficiency

Alongside the addition of predictive commands, there have also been a few interface updates in terms of how users interact with geometry. These are all intended to make things either clearer, less jarring or more efficient.

This drive for design efficiency is something that Siemens has been working on for a while. A good example from NX 12 is where some areas get ‘greyed out’ when you’re building geometry out (see Figure 1). This helps you focus on the task at hand and makes a lot of sense.

A more recent update makes the process of selecting your work part more efficient. In previous releases, you would need to select the part and then make it the work part manually. NX now does this automatically.

For example, if you select an edge to apply an edge blend (a fillet), NX will automatically select that part and make it active. If you then select an edge on another part and do the same, it’ll automatically make that the work part. No other input is required.

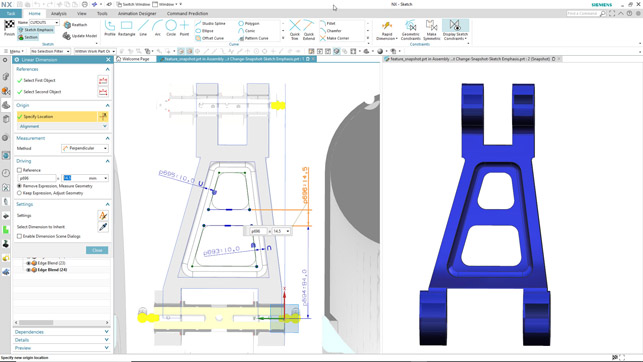

Also interesting is the feature snapshot update, allowing you to open a model and create a snapshot that then opens up in a separate window alongside your regular model view. Then, as you make edits to your model, it shows you the result of those edits in the synchronised additional view. What this enables is the ability to work on earlier features in a part’s history and understand the impact of changes downstream. In this way, you can visualise how edits will affect your final part.

The last two general updates in terms of user experience include a new addition to the help system and a new method of interacting with very large assemblies. On the help system front, hitting F1 when in a command will pop up a very brief video to whizz you through the option, then link you to further documentation where available.

This new feature, called First Assist, is a nice touch, but it’ll also be backed up in a forthcoming release with a new tool called Electronic Visual Assistant, which will extend this to work within the command the user is currently using. It opens a live Visual Assistant graphics window with objects in the assistant synchronised with corresponding elements in the command dialogue, promoting visual learning of NX that may be especially helpful for new users.

Moving onto loading of large assemblies, NX has, for some time given you a lot of control over this process. This takes advantage of some smart use of the product structure, as well as NX’s inherent smart, lightweight approach to faceted data (via the JT format). Now, there’s an assembly loading option called ‘minimal loading’. This streams the assembly into your window.

You’re able to interact with the product structure and the parts already shown, but you can also quickly hide sub-assemblies that you don’t want, as well as measure, section and so on. At any point, you can pause the load or stop.

Siemens NX – Meshes and convergent modelling

Let’s now talk about convergent modelling: if you’ve not kept up to date with this, it’s a new technology that allows you to work with mesh-based geometry in a similar way to solid and surface geometry. In other words, you can apply operations that you’d typically associate with more traditional modelling techniques.

Essentially, meshes are becoming firstclass geometry types in NX, where other systems treat them as second-class citizens.

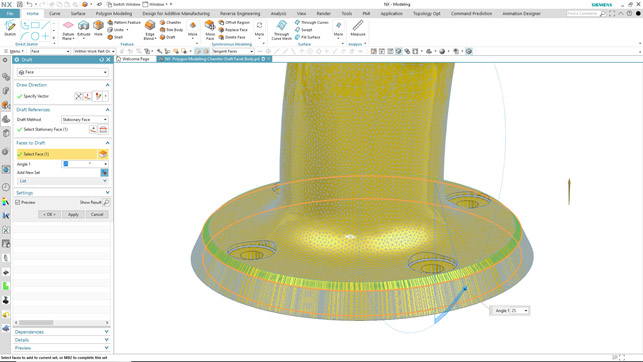

In the previous major release, NX 12, we saw filleting or edge blends work on meshes.

This has been extended for this release with the ability to not only chamfer, but also to add draft around a mesh ‘edge’.

For long-term geometry nerds like me, the ability to accurately add draft to a mesh might seem like voodoo. What’s happening under the hood is that you’re using selections on the mesh, while the system builds a set of surfaces according to those selections, makes the edits, then adapts your mesh to match.

There has also been some development work done to help fix the issues often encountered when working with mesh data (particularly in reverse-engineering processes). These range from the typical unifying of flipped normals and selfintersections, through to more complex tools to help find and fill in holes (including a range blending options and bridging tools).

There are also some nifty new tools for smoothing meshes – a task often required when reverse engineering with laser scanners. These tools allow you to either quickly brush across areas or to have the system treat the mesh as a whole. There are some handy visualisation tools available now that let you quickly find areas of curvature change that indicate either a sharp edge or defect in the mesh.

Long-term NX users will know that these types of tools are not exactly new. What has changed, in fact, is how they have been integrated into the convergent modelling environment. Now, if you have a mesh you need to work on, you switch into the ‘polygon modelling task’ environment.

Then, once you have that ‘polygon’ entity in your history tree, you’re able to add in further operations. Where this brings real benefit is if you need to subsequently make edits to that polygon mesh, you can do so, and then have the downstream features update.

In a final update on the mesh front, there has been a rewrite of the remesh command.

This gives you a couple of useful options. Firstly, it’ll remesh based on a constant size, so you have the same size facets across the whole of your part. This is useful for downstream processes, mostly involving FEA-like processes. There’s also a variable size remesh option. This refines your mesh based on curvature (because more curvature means more facets), and it also has a sharp edge lock, so you can preserve feature definition.

Lattice structures

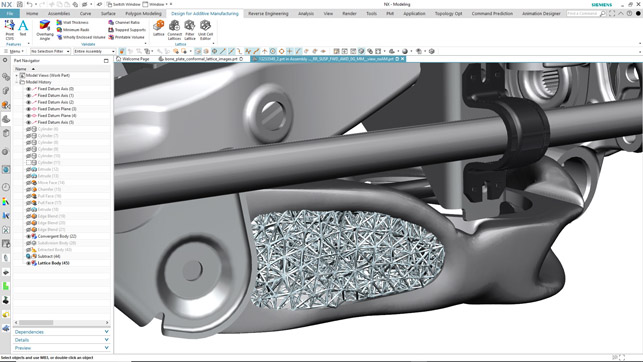

Another update first seen in previous releases and continuing to develop is work on the lattice design tools inside Siemens NX. The latest updates bring not only a wide selection of build into cell types (the geometry that is replicated to form the lattice), but also the ability to define your own.

As ever, this is done within a square cell form in which you can start to build up your beam network and interconnections.

Interestingly, there are a number of preexisting templates, but the system also gives you feedback as you build things up (such as where beams are disconnected).

Also new in this area are new tetrahedral lattices, giving you more options and ways to build lattices, as well as some tools to help connect disparate and disconnected lattices into cohesive single forms.

Animation designer/inverse kinematics

Let’s now move onto a new area for Siemens NX, with the addition of inverse kinematics in NX Animation Designer. Most of us should be familiar with the idea of being able to create timeline-based animations in our CAD systems. Almost all of these systems now include these kinds of tools.

Siemens developed Animation Designer in NX 12 to provide a similar level of functionality, on both a single part with just solids and curves, and fully defined assemblies, but now has the addition of inverse kinematics in this latest release.

What this means is that while you’ll be able to create your animations in the normal way – moving your parts, creating a keyframe and having the system move it – you’ll also be able to do the same with connected parts in a sub-assembly. Imagine moving the end effector on a robot arm: you move just the end into position and the system works out the rest.

These joints can be brought across from the standard Siemens NX environment, but if you need to ensure that your assemblies move in the right manner and within their physical limits, NX Animation Designer also offers ‘motors’. These are useful on those occasions when you want to limit the movement of a joint – either its angular range or linear distance. It’s worth noting that these animation-specific joints and motors are independent of the main NX product structure and you don’t need to adhere to those already defined in your assembly.

In addition to the basic set-up tools, there are some well thought-out additions to help with communicating ideas clearly and distinctly. Almost everything can be animation, from visibility and colour to automatic explosions of assemblies.

This final one is interesting. As usual, you grab your part or sub-assembly and define the vector for movement – but the clever part is that the speed at which you drag the selection corresponds to how long the movement lasts in the timeline. Drag it quickly, the explode action is fast. Drag it slowly, and the system adds more time.

Strangely, this data can’t be reused in NX’s rendering environment at the moment, but you can take the data you’ve created into NX Motion for simulation studies and Mechatronic Concept Designer, which is useful for commissioning studies and so on.

Siemens NX & instant VR

Siemens has been talking about virtual reality (VR) for a while in connection with its design products. While it has had, for some time now, a set of tools in the more traditional virtual reality vein, with its digital mock-up toolset in Teamcenter, this is more about taking advantage of today’s dramatically cheaper VR hardware directly inside the NX interface.

Built on top of a set of technology from British start-up, Masters of Pie, NX now has some very nifty VR capabilities that support the HTC Vive (no Oculus support as yet), so you can be inside your NX session, hit the VR button and off you go.

Assuming that all of your hardware is connected, this single button push takes your onscreen data and transfers it to a clean and clear VR environment. From here, you can walk around your product and inspect it at full scale. If you’re working on very large products or your VR workspace is restricted, then the teleport function will allow you to move digitally.

On your left hand, you have a number of menus that give you access to a range of tools: for visibility control for parts and sub-assemblies, measuring and sectioning, as well as snapshot and markup (which are output as jpegs).

Siemens NX – Manufacturing cost analysis

The last update area for NX that we’re going to look at is new tools to help discover more information about the cost of the product on which you’re working. Siemens has, for some time, been building a set of tools that allow you to gain more understanding of your products’ status from a combination of geometry, lifecycle data and information gathered from elsewhere in the enterprise.

In the first instance, these tools are found in the NX Feature to Cost module, which carries out a functional analysis of your part with regards to either cavity tooling for injection moulding or for stamping/forging. This looks at mouldability of the part, finding potential split lines, identifying whether there are areas of undercut (requiring slides or lifts) as well as tall features that indicate the need for sparking operations in the tooling.

What’s interesting is that this data can then be used as the basis for further investigation and prediction, using a preexisting tool called Teamcenter Product Cost Management, which is somewhat misnamed, because it can be used entirely separately from Teamcenter.

This will use this geometric information as the basis for further costing analysis that factors in material costs, location, processing and so on. Of course, while this is supplied with a large database of generic information, it can also be populated with your own company’s data where needed.

In conclusion

NX’s shift to a continuous release cycle is going to be interesting to watch. We’re accustomed to newer 3D design systems taking this approach, where risks are much lower and the bar for robustness might be similarly so. But when you’ve got a toolset like NX, with decades of development and use across a wide range of serious industries behind it, anything that inconveniences those enterprises already using it in production will very quickly become apparent.

That said, earlier indicators show that many of Siemens’ customers, particularly those that are newer to the system, are keen to adopt the idea of smaller, more frequent updates. Only time, as they say, will tell.

In terms of what the team has delivered in the short period between the last numerically tagged NX 12 release and this most recent update is quite remarkable. It not only builds on existing capabilities and recent introductions (such as support for more control over lattices and expansion of convergent modelling techniques), but also adds in brand new tools, such as the VR support (which is excellent) and the new adaptive user interface, which is going help long-term users reach their most-used commands quickly, and get new users up to speed more quickly.

| Product | NX |

|---|---|

| Company name | Siemens |

| Price | on application |