EinScan Pro 2x Plus – Shining3D has built a reputation for affordable, high-performance 3D scanning devices. We get to grips with its latest device, which offers flexibility and affordability, and comes with some very helpful, easy-to-use software

When it comes to 3D scanning and form capture devices, there are a wealth of options available today, ranging from the very low-cost through to the eye-wateringly expensive.

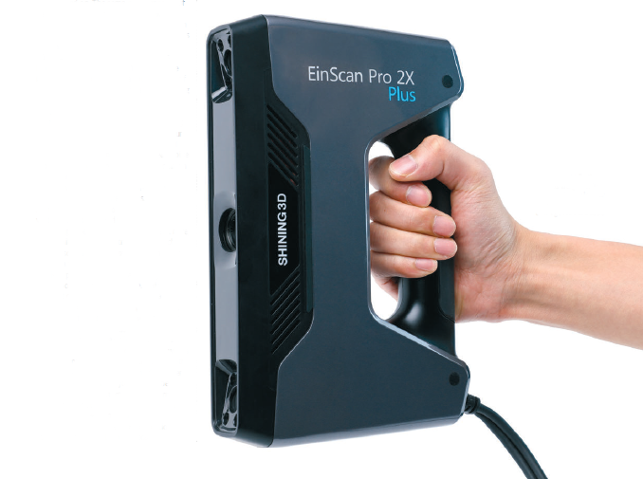

The EinScan ProX 2X Plus weighs in just over 1kg, so longer scanning sessions don’t get too arduous

As well as cost, the form-factor of devices varies wildly, too. We have depth sensor-based products that can give you a rough-and-ready scan for a couple of hundred quid; laser and white light-based handheld devices; scanning heads attached to measurement arms; and drone-mounted LiDAR systems for huge scan sets. If you’re looking to capture form from reality, the world is your proverbial oyster.

While the EinScan range has been on the market for a few years now (we looked at an earlier product way back in 2009), things have moved on. The same core concepts of flexible hardware and automation where needed still apply, but the optics have been improved, as has the software capability, as we shall see.

The core part of the EinScan range is a handheld scanning device. This is a white light scanner, so it’s using a combination of a projector in the middle of the device along with two cameras on the left- and right-hand sides. An image is projected from the centre of the device (this varies depending on the use mode), the two cameras capture how that image forms on the object, and some clever maths means that for each pixel projected, the device works out its position in 3D space.

The new EinScan Pro 2X Plus is an all-round upgrade on previous iterations. It’s the same compact unit, powered and connected via the same cable and weighs in at just under 1kg. The bundle we’re looking at here, meanwhile, is the industrial pack, which adds in something that sets EinScan devices apart – a turntable.

This is perhaps the company’s biggest selling point (apart from price, which we’ll get onto later): the EinScan Pro 2X Plus is a multifunction scanner. In its purest form, it’s a perfectly capable handheld scanner.

You use the device to pass over the surface of your object and the software tracks its position (using a number of methods, which we’ll get onto shortly), and you end up with your 3D geometry. This is useful for larger objects or those where you need to be able to point the light into hidden corners.

Essentially, the object stays still, and you move the scanner around it.

It can also be used as a fixed-position scanner, where you keep the scanner static and the object moves. This can be done by placing the scanner on a standard tripod and either manually rotating the object or using a turntable. This might be a manual turntable (a cake decorating stand is excellent for this) or one that’s powered. While this method doesn’t offer the flexibility of handheld mode, it does give you more accurate results, which are worth detailing.

EinScan Pro 2x Plus- scanning modes

When used in handheld mode, there are two options for the EinScan Pro 2X Plus: Handheld HD and Handheld Rapid Scan. HD Scan gives you accuracy up to 0.05mm (at a volumetric accuracy of 0.3mm/m) and scans at 20 frames per second (fps). To use this mode, you need to use registration markers on your object (small, reflective, self adhesive dots).

Considering the resolution of the scanner, this mode creates a huge amount of data (we’re talking 1.1 million points per second).

Handheld Rapid Scan, on the other hand, reduces the accuracy of the scan to 0.1mm, but can use a number of methods to track position. It’ll use markers, feature scanning or hybrid mode, which uses a mix of both.

This scans more quickly (at 30 fps), and again, generates huge datasets at a rate of 1.5 million points per second.

Then you get onto the fixed-scan modes (both of which are only available with the industrial pack). Here, you’re looking at scan resolution rising to 0.04mm, with each scan taking less than half a second.

The scanner only takes one shot per position, so the data capture rates typically aren’t as high, but if you’re scanning an object using the turntable and max out at 180 shots (one shot for every 2 degrees of rotation), it’ll soon add up.

In fixed mode, you have similar options for tracking and registration of your separate datasets. You can use the coded targets on the turntable (useful for smaller objects), features, markers or work through a manual alignment process using three common features between separate scan sets.

EinScan Pro 2x plus – set-up process

The device comes in two separate boxes – one with the handheld device and all of the sundries (registration plate, power brick, cables and software USBs and so on), and another with the turntable, tripod and its associated power brick.

Starting with the scanner itself, set-up is pretty easy. You connect up the USB (you’ll need a spare high-speed port) and the power supply, both of which connect to the same cable, and start the installation process. Set-up is simple and we didn’t encounter any issues with either installation or licensing.

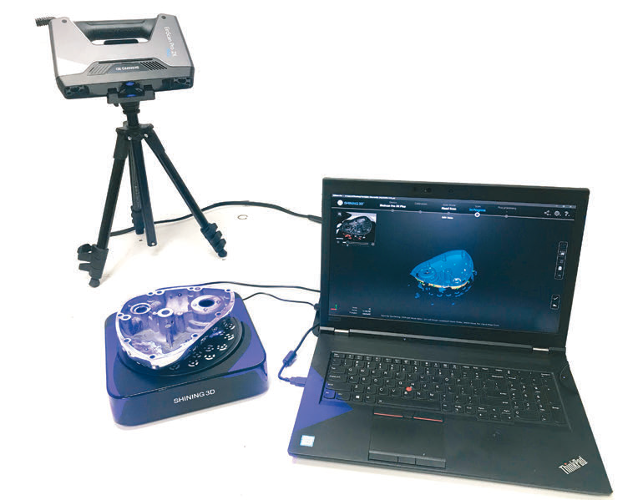

A couple of things worth noting at this point: the first is that you’ll need a pretty speedy machine with a decent GPU on board, and you’ll need to consider how you’re connecting to your machine.

Though the minimum workstation spec is an NVIDIA GTX660 or higher GPU with 8Gb RAM, we used a beast of a Lenovo P72, which is much better suited to larger datasets, particularly when fitted with 64GB of RAM and a P5200 GPU.

The second thing is to consider your work area and process. If you’re using the fixed mode, this isn’t so much of an issue, but if you’re working in handheld mode and on larger objects, you need to consider how your device is connected to your workstation.

The risk here is that you’ll strain your USB port, dragging your scanner and cable around. Consider using the supplied USB hub (or an alternative) and fixing it to your work area (perhaps with Velcro pads). This will save knackering up your USB slots.

If you’re using the turntable, you’ll also need to unpack this. It’s a pretty simple USB-connected device and set-up is a breeze. What isn’t so slick is the tripod supplied inside the Industrial pack. The device comes with a mounting bracket with the standard 1/8inch threaded insert for a tripod. Take my advice: buy a half-decent one instead (we used a Manfrotto that we already had in the workshop) and chuck the supplied tripod in the bin.

The final stage in set-up is to run through the calibration process. A calibration plate is supplied in the box and you run through a 10-minute process, scanning this plate in different orientations.

Our test set-up, using the Industrial Pack, along with a Lenovo ThinkPad P72 with enough power to handle the data that scanning generates

EinScan Pro 2x Plus – in use

Now you’re ready to start your first scanning project. To run the set-up through its paces, we tried several projects.

The first involved a sculptural item, because we wanted to see how the Handheld Rapid Scan mode works and how well the recently updated ExScan Pro software handles that sort of rapid and heavy data load. As ever, we used our trusty gargoyle, Ted, and once we’d got our eye in, in terms of how best to handle the scanner (in terms of speed of movement, distance from the object and so on), it proved pretty simple to get him scanned up.

The benefits of this method (and object) is that you’re able to very quickly learn how to manipulate the device to grab those deeper pockets, using both the on-screen display and the projection on your object.

Ted is a good test subject, because he scans readily and has enough textural detail to make tracking easy without the need for registration markers.

I have to say at this point that Shining3D has clearly put a lot of work into its software recently. When we last looked at it, it was functional, but lacked clear workflows. Fast forward to today and the software is up-to-date, the experience is slick and you’re guided effortlessly through the process.

To test out the fixed scanning modes, we scanned a motorcycle timing cover.

Again, it’s a useful test part; the internal parts are essentially prismatic, offering a range of detail complexity (from threads to embossed lettering) and accessibility issues (in terms of line of sight from the scanner to the surface). It’s also a matt finish from the casting process, so scans nicely. The exterior, meanwhile, presents a very different challenge. With a highly polished aluminium surface, smooth surface forms and not much in the way of texture, scanning this side efficiently is a trickier job.

To help the process, we dulled down the surface with car polish to cut back on the reflectivity that can screw up a scanner pass. For both sides, we also used a number of reflective registration markers that assist with registering each scan with one another. If you’re lucky and your part allows it, it’s also possible to use these to register two separate set-ups together in the same project file. If the software can see the same markers in two scans, it should be able to match them up – and in our experience, does a pretty good job of it.

The set-up process requires that you define the number of scans you want to carry out in a 360-degree rotation (the option to limit this to a specific angle would be brilliant). The minimum is two, the maximum is 180 separate scans. When you consider that each scan is generating something of the order of 600,000 points, you quickly realise that you need to be clever about finding the right balance between limiting the numbers of scans and capturing sufficient detail. We found it best to start out with a simple, quick scan (say, eight of these), see where you get to, and then adjust accordingly.

At this point, the software pays real dividends. As you complete each scan set, it’s organised in the browser. You’re also able to tidy up each scan, either as a set or as a group, select points to remove (scanned, perhaps, from the surrounding data, the turntable and so on).

It’s not immediately obvious, but the tool The first involved a sculptural item, because we wanted to see how the Handheld Rapid Scan mode works and how well the recently updated ExScan Pro software handles that sort of rapid and heavy data load. As ever, we used our trusty gargoyle, Ted, and once we’d got our eye in, in terms of how best to handle the scanner (in terms of speed of movement, distance from the object and so on), it proved pretty simple to get him scanned up.

The benefits of this method (and object) is that you’re able to very quickly learn how to manipulate the device to grab those deeper pockets, using both the on-screen display and the projection on your object.

Ted is a good test subject, because he scans readily and has enough textural detail to make tracking easy without the need for registration markers.

I have to say at this point that Shining3D has clearly put a lot of work into its software recently. When we last looked at it, it was functional, but lacked clear workflows. Fastforward to today and the software is up-to-date, the experience is slick and you’re guided effortlessly through the process.

To test out the fixed scanning modes, we scanned a motorcycle timing cover.

Again, it’s a useful test part; the internal parts are essentially prismatic, offering a range of detail complexity (from threads to embossed lettering) and accessibility issues (in terms of line of sight from the scanner to the surface). It’s also a matt finish from the casting process, so scans nicely. The exterior, meanwhile, presents a very different challenge. With a highly polished aluminium surface, smooth surface forms and not much in the way of texture, scanning this side efficiently is a trickier job.

To help the process, we dulled down the surface with car polish to cut back on the reflectivity that can screw up a scanner pass. For both sides, we also used a number of reflective registration markers that assist with registering each scan with one another. If you’re lucky and your part allows it, it’s also possible to use these to register two separate set-ups together in the same project file. If the software can see the same markers in two scans, it should be able to match them up – and in our experience, does a pretty good job of it.

The set-up process requires that you define the number of scans you want to carry out in a 360-degree rotation (the option to limit this to a specific angle would be brilliant). The minimum is two, the maximum is 180 separate scans. When you consider that each scan is generating something of the order of 600,000 points, you quickly realise that you need to be clever about finding the right balance between limiting the numbers of scans and capturing sufficient detail. We found it best to start out with a simple, quick scan (say, eight of these), see where you get to, and then adjust accordingly.

At this point, the software pays real dividends. As you complete each scan set, it’s organised in the browser. You’re also able to tidy up each scan, either as a set or as a group, select points to remove (scanned, perhaps, from the surrounding data, the turntable and so on). It’s not immediately obvious, but the tool tips at the base of the screen indicate how holding shift and dragging a lasso around points selects them; Ctrl removes them from that selection set; and then there’s an option on the right that pops up to allow you to delete them (highlighted in red).

Post-processing stage

If you’re looking to scan a part in one pass, you can then move onto the post-processing stage. If you’re working on a more complex part, you have a couple of options to play with. You can adjust the part on the turntable, you can move the scanner (we found having both a standard and a small, low tripod was handy) or you can use a combination of both approaches.

To achieve a good scan of the internal details of the test part, we elevated the scanner above the part and shot it straight down into the cavities. You’ll quickly work out how best ways to use these types of devices.

Then comes the fun of registering these separate point clouds together. As we’ve said, if you’ve managed to get common registration targets between scans, the software should do a half-decent job of bringing them together. If not, you can use the age-old process of identifying three or more common features (perhaps junctions of features, cylinder edges, or faults on the parts) and letting the system do a best fit.

Once this is done, you can then start to clean up your scans as a whole. First, you’ll mesh it (a pretty simple process), and you have two options: to simply mesh the point cloud as is, with holes; or to create a watertight model.

If you’re confident that your scan is good enough and clean enough, the auto-filling and watertight model option is handy, but I would imagine the more manual process might be better for those working to reference scans in other processes.

This then allows you to work through hole-filling and other clean-up process, either inside ExScan Pro (which has some decent hole-filling tools) or a more specialised tool. This might be built directly into your CAD system (there’s a direct link to Solid Edge from the software) or it might be a specialist scan post tool, such as 3D Systems, Geomagic Essentials, or PolyWorks. Ultimately, your export is typically going to be some form of mesh-based file, so you have a choice of STL, OBJ, 3MF.

EinScan’s interface is much improved and presents all the information you need to achieve decent scans, whatever your preferred method

In conclusion

The physical form capture market is one that’s slowly changing, and the technology is becoming more affordable.

At the high end, where you’re looking for metrology-focused solutions, things stay pretty pricey, but at the other end of the spectrum, there’s seemingly endless choice.

This applies whether you’re needing a quick-and-dirty scan to roughly check fit, or a more accurate scan for reverse engineering into a mesh-based file that accurately represents the physical object scanned or provides the basis for more analytic solid and surface modelling to replicate, reference or redesign it.

There are those who need to be able to scan smaller parts in very precise detail and those who need to scan larger parts, particularly those working on automotive and architectural projects.

Of course, the chances are, you probably need all of these options at different points – and this is where the EinScan fits very nicely indeed. It’s fast and flexible enough to be used in hand-held mode, scanning larger or more sculpted parts or products, but when you need to nail things down, you can switch to fixed mode – or indeed, use a blend of the two approaches.

It’s also priced in a way that makes it way more accessible than many other products out there. But perhaps the most impressive thing about the latest generation of the EinScan devices is the work that Shining3D has done on the software supplied with the hardware, which has come on leaps and bounds since we last worked with one of its devices.

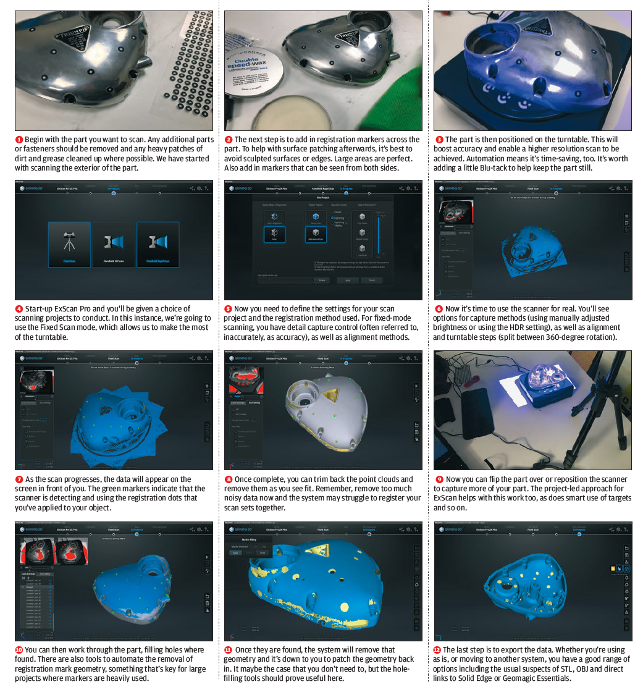

Workflow: Using the EinScan Pro 2X Plus Industrial Pack

Using any 3D scanning device is always a matter of experimentation and learning on the jog. The EinScan Pro 2X Plus device is no different. Handily, the company has made a number of videos and tutorials to help you along the way, as well as a pretty decent manual.

As we familiarised ourselves with the various modes, it became pretty apparent that the usual rules about 3D scanning apply here. Scanning dark and highly reflective objects, for example, can be difficult with any device (Tip: You need to lighten dark surfaces, dull down the reflective ones), but also there are a number of tips that seem to apply to these devices specifically.

The first is that if you’re using the turntable and fixed scanning, the turntable can be a little enthusiastic when it moves, so you need to fix your object down (Blu-tack works well).

The second is that when you’re working with the tripod, you need to be very careful with the bracket that holds the scanner in place. This is a little flimsy to say the least, but I’m sure a 3D-printed improvement would not be too beyond most of us and might be advisable if you have the facilities. (You’d just need a 1/4-inch threaded brass insert to fix it up to any tripod.)

Lastly, think about your workspace if you’re doing this in an office. You’ll need not only to have freedom of movement of the scanner, but also be able to see, and interact with, your computer screen. This is where a mobile workstation comes in very handy indeed, particularly if you need to pack up and head to the customer or worksite to scan.