Onshape Q1 2018 – With an expansion of sheet metal tools, more flexible and powerful sketching and new standard parts libraries, it looks like development continues apace

If you’re unfamiliar with Onshape and what the company has been doing since launching a couple of years ago, I think it bears repeating.

Onshape has applied its new approach to configurations to Standard parts libraries — saving management and centralising their use for all users

Founded by some of the original team behind SolidWorks, Onshape has become one of only a few 3D CAD vendors to start exploring the potential of CAD in the cloud and the geometry creation parts of product design.

Right out of the gates, Onshape differs from others in that it has taken a 100 per cent cloud-based approach. Everything is done in the browser and you need a live connection to enable it to work. No local files, no install. Open your browser, log in and you’re ready to get to work.

The last two years has seen the system evolve at a pretty impressive rate. While it launched with a fairly bare bones set of prismatic part design functionality, we’ve seen surface creation, greater sketch control, drawing creation, sheet metal design and much more added in the intervening time.

At present, Onshape covers most of the basics and for many, the system’s toolset in will be just about enough to get the job done. There will always be those that need a specific feature, a specific set of functionality and these things will get solved in time.

What’s perhaps most interesting about Onshape is how the system handles your data in the background. There’s no file system but still Onshape can accomplish some very interesting feats that would be difficult in other systems.

While these are challenging to describe succinctly, it all boils down to the fact that almost everything in Onshape is individually version managed and referencable. In the context of part design, this means that your change management (in terms of version, rather than revision history) comes as standard and just works out of the box.

In the context of more granular data inside each part, there’s much more to play with. For example, in the previous releases, Onshape introduced the concept of incontext editing of parts which is a great deal more flexible than in traditional modelling systems (see the Onshape Q2 2017 review) . But more recently, the updates made to the system push this even further and look to reinvent a commonly used feature set found in most CAD systems — configurations.

When you step beyond the small scale examples in a single part, things can get complex very quickly indeed. Once you start to factor in managing multiple variables and inputs, the parametric dimensions they drive, feature suppression and assembly structures, then you have the challenge of ensuring that such assets are controlled, managed and rolled out in your organisation (whether that’s internal or, indeed, externally with suppliers or customers).

So let’s explore how Onshape is addressing some of these issues and what else it has up its sleeve.

Onshape Q1 2018 – standard parts library

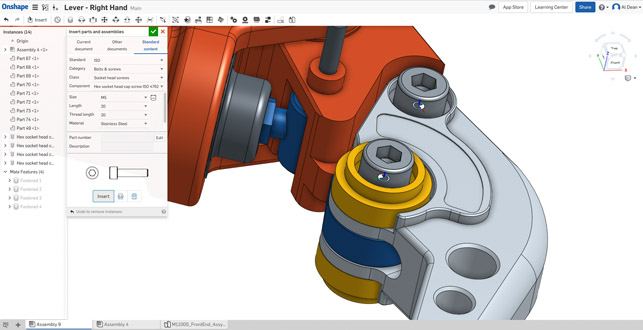

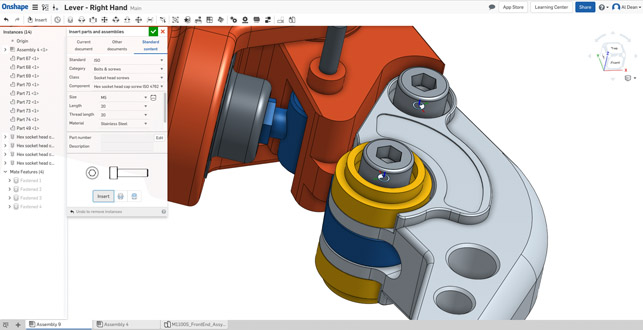

The first area and most widely applicable to all users where Onshape has applied its new approach to configurations is in the world of standard parts. In this first release, we’re talking about a set of tools that allow you to add in the most common bolts, washers and nuts from an integrated library.

What’s interesting here is that there’s no installation of the libraries (à la Toolbox in SolidWorks) and all users share the same component library. To make use of it, you use the Insert operation in your Assembly Studio (as you would other parts) and you’ll see the ‘Standard Content’ tab.

This allows you to filter down to the part you want, choosing from the familiar array of categories, classes and standard sizes.

Once that’s complete, it’s time to insert it. Here things get interesting as each of these components has been built using Onshape’s standard mate connectors.

This means that it’s imbued with knowledge of how it’s to be assembled. If you want to insert a single instance, snap to a corresponding mate connector on your part and it’s done. If you have multiples, you can have the system find them automatically or select them yourself.

Furthermore, once you have one fastener in place, you can start to add in your stack of washers and nuts as applicable. Again, there’s some intelligence in place so that the system is aware of how parts stack and it’ll automatically bump parts around your stack as you add them in.

While Onshape has done a decent job of automating some of those more repetitive parts of the fastener addition process, there are variants of it available in other systems. Although this is nothing new, where things really differ is when you start to share your product models, either internally or externally with partners. With other file-based systems there is the potential for the export or copy process to miss your standard parts, or there being a mismatch between systems and installations — all of which add up to a massive pain in the backside to fix.

Onshape does away with this rather efficiently. As everyone uses the same standard parts library, which is centrally managed, you never have these issues. Send a customer a part or assembly and it’ll open up in their Onshape account exactly how it appears in yours. No searching for missing M8 bolts, no searching your hard drive for that obscure ISO button cap screw.

Configurations are managed in a more granular manner, meaning no more searching through the spreadsheet of doom

Onshape Q1 2018 – Configuration

So how can we use this approach to benefit our own work? Configurations are beneficial to many and judging by the reaction on the Onshape forums, this has been a much requested capability. So how does it work?

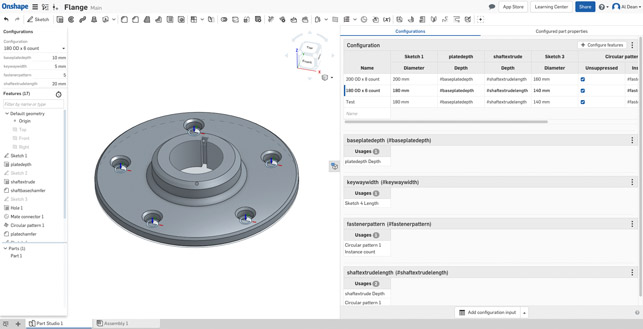

The answer starts pretty traditionally with a parametric, feature driven model. Once you have your part designed and working as you want it, you can then start to build out your configurations for that part.

Configurations in Onshape are pretty simple to set up — particularly as it’s done in the same window. You’ll notice a small tab to the right hand side of your model window. Hit this and the configurations panel opens up. Here, you can start to configure your parts and provide a name for each configuration.

Then you can select the feature and then the dimension you want to control or define options for features (to control suppression). You’ll see that these are quickly populated into the configuration table and you can then populate the values you need for each configuration.

They can be hard values, driven by equations — and you can also mix and match units, which is particularly useful for those working across borders.

Where things get interesting is when you need to define more complex inputs into the model. For example, you could have a shaft that has a length range of anywhere between 100mm and 350mm. With a traditional configuration table, you’d need to define a row in the config table for each instance between those limits. Onshape differs in that you can create separate inputs that has a range and works across linear dimensions, angles and more.

There are also options to add a separately managed list of inputs — effectively splitting out the configuration of a single set of features into a new, much smaller table. The goal here is to reduce the complexity of the process and the reliance on that traditionally monolithic spreadsheet and break it down into much more manageable chunks. What’s also interesting is that these smaller confi gurations can be reduced in the part studio.

This will be particularly useful when driving options and variants across multiple parts, which might have the same references. There’s also a work around to share these input tables across multiple parts in multiple projects using the derive part functionality, so you can quickly ensure that part interfaces are standardised.

Now, if you’ve been following Onshape’s development, you’ll also be familiar with its FeatureScript functionality that it introduced last year. This allows users to program their own features and functions (Onshape uses the same language to define its own operations) and it’s pretty accessible. Using FeatureScript in combination with the Configurations panel means you have some serious customisation tools available in the system.

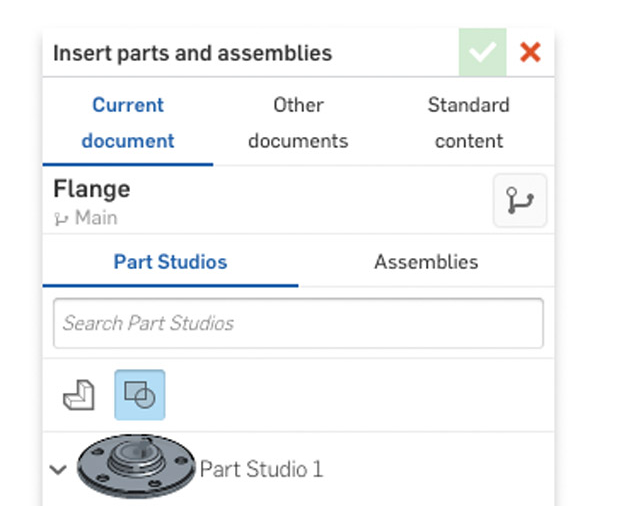

Of course, defining the Configurations is one thing, reusing them is another. As you can see from the image below, once you have your configurable parts working, it’s possible to reuse them very quickly. The insert operation pops up a nice clean dialog from which preset variants can be selected and any more open variables set.

What’s interesting here is that this is all centralised and managed. Sharing this data with another user (either internally or externally) will allow them to use it in exactly the same way — no transferring complex part files and spreadsheets.

Configurations are pretty slick when it comes to reusing data and parts (Click here to enlarge image)

Onshape Q1 2018 – sheet metal updates

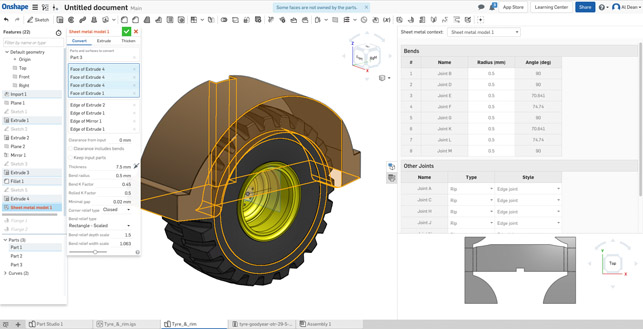

Let’s move onto the sheet metal tools. Introduced in the last six months, these have been maturing with each release. While we’re yet to see the introduction of more complex sheet metal features (such as louvres and stamped forms), there have been some nice additions to the toolset.

Perhaps the most useful is Onshape’s new ability to identify larger radius arcs and define them as rolled forms and give you control. This enables you to flatten out your larger features but still retain your standard bends as you did previously.

In the image above, the larger form around the tyre is a rolled bend and flattens out correctly, while the smaller bends conform to your sheet metal rules.

It’s also worth noting that the bends and rolled forms (shown as tangent bends) are separated out in the tables on the right hand side.

The first is the ability to quickly sketch out a set of tabs in your parts. These would typically be found where flanges intersect and used to close up a part or to bridge between two areas of a folded form. They might be left as is or welded up. The implementation is pretty slick.

You simply sketch out the intersectional tabs, use the Tab operation to select what gets cut from where, select a set-back value (for your gap) and bingo, you’re done.

Other updates

Alongside the updates we’ve discussed here, there are a good number of new features and functions that aren’t quite such big ticket items, but all of which add into the maturing of the system. So let’s have a little look at a few of my personal highlights.

The first is the new ability to manage your materials libraries. While Onshape, at present, only holds name and density (for massing calcs, presumably), there’s now the ability to import and manage your material libraries and share them across your organisation. It’d be nice to be able to pull data across from some of the web-based material spec sites (such as Matweb), but this works in the mean time.

Another useful update focusses on the creation of more complex geometry, particularly when building parts using surfaces. As we’re all aware, good surfacing often boils down to good sketching and curve network creation.

To assist with those instances where you need to guide a surface’s creation between two existing surfaces, the new Bridge Curve tool will come in handy — particularly given that it has some tangency and curvature controls built in.

Finally, there’s been a fair bit of work done on the drawings environment. These updates range from a reworking of view rendering, which gives you much clearer lines in your views, through tweaks and improvements to GD&T tools, into drawing view management, especially useful for those that are using multiple sheets heavily.

The Onshape sheet metal tools now automatically detect forms that can be rolled, assuming they’re built on arcbased profiles

In conclusion

Onshape is pitching the last couple of updates as bringing its vision of Parametric Modelling 2.0 to life. Its argument being that the Feature Script tools combined with Onshape’s innate share-ability and the new Configuration and standard parts capability are enough to justify this being a totally new approach to parametric modelling, which has now been on the market for over two decades.

Whether or not that’s valid isn’t really up for debate here, it’s more a marketing message than anything else.

What I can tell you is that having watched Onshape mature in the last year, it’s clear that the company is doing some truly interesting things. While the early days saw a heavy focus on its ‘revolutionary’ cloud-based nature, we’re now progressing beyond that and starting to see some truly new functionality come into the system, rather than pure replication of ‘what’s gone before, delivered in a new way’.

The new tools we’ve focussed on here show that it is possible to find room for new thinking in an area of 3D design technology that many might have assumed is an innovation dead-end.

The new configurations tools look to break down the complexities of such processes, while the delivery of standard parts using the same tech shows the power of using the cloud — anyone that’s wrangled with standard parts libraries across a group of users will know the pain that’s often involved.

| Product | Onshape Q1 2018 |

|---|---|

| Company name | Onshape |

| Price | $125 per user per month |