CSI’s DesignDataManager (DDM) has been on the market for over two decades. Its background grew out of a requirement in the PTC user community for a more simple engineering data management solution than was offered by PTC at the time.

While that is its heritage, the intervening years have seen the system grow up in terms of increased capability and which systems it works with (namely, all of them). As that expansion of both aspects has continued, the system has also kept up to date with user requirements and its two key tenets — simplicity and affordability — have remained. So let’s take a look at where things are now.

It’s at this point that you start to get a feel for DDM’s focus on ease of implementation. Whereas data management systems are renowned for being overly complex and requiring large amounts of consultancy to set up, DDM has been developed to keep this to the bare minimum and configured in a way that gets you up and running quickly.

There’s even a 30 day trial — something that is rare in the world of data management. So let’s step through the process to give you a flavour.

DesignDataManager – Set-up & configuration

DesignDataManager is a client server-based data management system — as such, you begin with the server set-up, then connect the clients to it. Download the software and the install wizard checks to make sure you have the correct server version and prerequisites in place. Essentially this comes down to needing Microsoft Server 2012. That’s about it.

You then start to install your client software and, here, things get interesting. DDM supports not only its own client application, but also integrates into the majority of CAD systems on the market today. Not just in terms of a cursory integration but true, in window integration, so use of your data management system becomes an integral part of your CAD system (undoubtedly a good thing).

At present, there are integrations with the likes of SolidWorks, Solid Edge, Inventor, Creo Parametric, IronCAD and AutoCAD, all of which come ready out of the box. It’s also worth noting that the system also facilities the management of any other office documents, such as Microsoft Office, Adobe documents, even single files, such as Rhino, for example, so any related documentation can also be stored in its vault.

The install process asks for some technical information regarding ports and which systems you want to integrate with (no matter which system/s you run, you manage your data in the same, centralised database).

Other than setting up basic user accounts, the system is now up and running. You’re then going to need to map the system’s capabilities to your data management requirements and then define the way it works for your organisation’s requirements, processes and workflows — and this is where things get very interesting.

DesignDataManager – Business process integration

Business Process Integration is a phrase that will probably strike fear in the heart of anyone that’s touched a PDM or PLM installation. While it has become a synonym for costly consultancy and configuration, the core idea is valid and deceptively simple — something that CSI has focussed on for DDM.

Once your infrastructure is up and running, you then need to start to flesh out how you’re going to use the system — and you might typically do this yourself.

Whether you simply want to centralise data storage and add in some version or revision management, the system also holds a huge amount of greater potential.

If you want to get into compartmentalising your work by project or customer, you can. It’s a simple case of switching that option on. If you want to dive into automation of part numbering, you switch it on. Options are there for all manner of design and engineering management systems.

If you then want to start to add in workflow and process management, the system is supplied with a number of workflows out of the box. These cover most common processes, from simple ECR/ECO workflows (with full visibility and traceability of decisions and sign-off), right through to non-conformance with the shopfloor or stock room/inventory, supplier audits and much more.

The goal here is that you start with the basics, get users used to it, then start to add in the advanced capabilities as use and time demands. Think configuration, rather than customisation.

Interestingly, this has downstream benefits, particularly for those responsible for administration of the system. Because you’re configuring templates, rather than wholesale customisation, you can adopt software updates quickly. This is opposed to updating base software than having to do all the configuration work over, each time (something that causes PDM and, in particular, PLM implementations to stall quite often).

Elsewhere, there are additional addons for helping to expand the reach of the data held within DDM to a much wider audience than traditional design and engineering and management, in particular with the DDM Web module, which allows you to expand use and interaction with that data using browser based clients, rather than the heavier CAD focussed install.

Now we have an idea of the install, set-up and admin from a business perspective, how does it look to the designers, engineers and managers who are using the system?

DesignDataManager – User experience

Let’s look at the design and engineering user first. These would typically interact with the system through their CAD system. Once installed, each CAD system gets its own ribbon tool-bar and icons to interact with the DDM database.

This allows you to push your data, once in a fit state, into DDM to start managing it. As an example, from within SolidWorks, this is done by simply hitting the Save icon. The same is true whether you’re using SolidWorks, Creo, AutoCAD or any of the other supported systems.

That operation brings up the DDM interface into which you start to define the data management meta-data.

As you might expect, this is fully configurable in terms of fields that can be captured, whether that information is mandatory, and much more. Once you’ve filled out these fields, you save it to DDM, the data is moved to the database and it becomes “managed”.

DDM has a pretty sophisticated understanding of the more complex structures of most 3D design systems, so it inherently handles assembly and sub assembly relationships, configurations or part variants (if your CAD system has them) and the relationship between referenced parts, assemblies and drawings.

Subsequent edits are version managed and if you’ve enabled it, you have full release management as well.

It’s here that the system moves beyond pure workgroup management and gets you into some serious PDM territory. In a multi-user environment, the ability to restrict access and editing to released components or sub-assemblies is a must — DDM has these capabilities at its core and the level of sophistication you want to get into depends on your requirements.

DesignDataManager – Data reuse

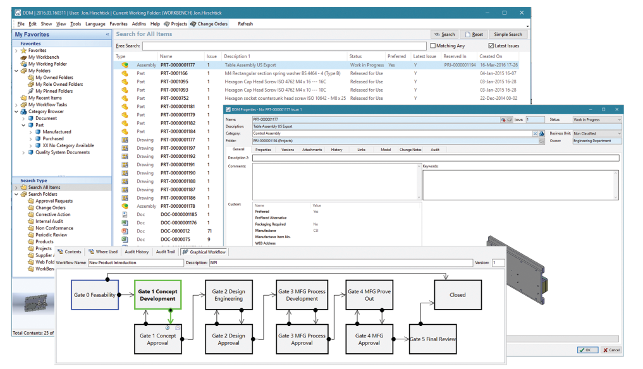

One of the universal benefits of working in a managed data environment is, of course, data reuse and reduction of repetitive work. It’s here that DDM’s search interface comes into its own.

Whereas search is almost a secondary thought in other PDM systems, within DDM it’s the main focus on the client interface.

Search can be done on a holistic level, across all of your data, filtered, organised and drilled down through. If you search by text string or by filtered classification, the system not only shows you rich information about each result, but also allows you to drill into related data, such as where a part is used.

This allows you to not only find data to reuse easily, but to also have immediate knowledge of the affects of any edits or revision of that data.

And the non-CAD user?

Of course, away from the CAD user, there are plenty of folks within any organisation that need to have access to this rich set of data or to interact with BOMs, workflows and processes.

Here, there are a number of options. They can, of course, use the DDM Office client application, this will give them the ability to carry out full search and use of the data, the ability to administer the system as well as participate in workflows and business processes.

If you also want to provide access to the information in a more widespread but more controlled manner (two often opposing ideas), then the DDM Web module allows this. This opens up access to the data (that you want to offer or provide access to) through a web browser.

That makes it ideal for all manner of folks involved in design and production, whether that’s on the shopfloor, purchasing or marketing as well as those outside your firewall, such as suppliers or customers.

Business systems

One of the more advanced capabilities that CSI also includes is the ability to integrate DDM’s data and meta-data with your other business systems, be they MRP, ERP or something else.

With DDM you can automate the passing of information to a number of different systems, out of the box. You essentially need to tell it what you want to pass across and when (in terms of revision change perhaps). It then passes this information into the appropriate folder and it automatically gets picked up by the other system.

Here, there are a number of options. They can, of course, use the Windowsbased client applications, but with the addition of the DDM Web module, this can be reduced to a browser based interaction method. Both are equally as valid and in these times of smartphones, having a lightweight view into your company’s processes and data, can be incredibly valuable.

DesignDataManager – In conclusion

While we’ve covered the basics of DesignDataManager, I should make the point that the system is rich in terms of capability, but that shouldn’t be construed as meaning costly.

In fact, DesignDataManager’s pricing is something that’s worth detailing — mostly because it’s surprisingly clear cut.

DDM Office, which gives you management of common office docs, costs: £600 per user (£150 pa for support), if you want Office plus CAD integration (for all systems it supports), that’s a little more at £1,000 (£300 pa for support).

If you want to add in the web components, then that’s £2,500 and, worth bearing in mind, that’s for an unlimited number of users. If you want to run the system across multiple sites, then there are additional costs to cover both database and full file vault replication (£1,200 and £1,800 per site respectively).

That’s the whole price list. There’s no tiered price, no per CAD module cost, no add-on costs for different workflows and processes.

DesignDataManager is industry proven and accepted in a range of sizes of companies, from one-man bands (yes, really), through a host of small to medium companies to large, household names managing data across multiple sites around the globe.

Anything that moves data management away from being a customisation and consultancy heavy process to something that fits better with the requirements of today’s engineering world is a good thing.

DDM wins in terms of ease of implementation speed, configurability, support for multiple systems and, of course, on price.

| Product | DesignDataManager |

|---|---|

| Company name | CSI Ltd |

| Price | See text |