Vital Auto is rewriting the playbook on evidential design loops in automotive design and innovation, using AI tools that were built in-house at the Coventry-based company

For Shay Moradi, head of technology at industrial design studio Vital Auto, AI is “a suitcase term”. It is commonly used to refer to many slightly different things, he explains: automation, machine learning, generative AI, and so on.

“We’ve not even hit peak fatigue on the term and it gets bandied about so much that it tarnishes some of the shine of doing genuinely useful things,” he says, speaking to DEVELOP3D as he travels back from an event in France to Vital’s headquarters in Coventry, UK.

Vital works with OEM design teams at automakers around the world and has spent the last decade pushing digital software and hardware to the limits. Its innovative work has embraced 3D printing and XR, for example, in order to help its clients prove out their designs, whether they’re for public-facing show cars or top-secret research projects.

In recent years, the company has focused a great deal on building its own tools. “You can deliver perfectly functional software with a very small team, using AI coding tools or low-code tools that incorporate AI functionality through APIs. In our case, we do both classic development for our clients and we prototype things fast and efficiently for internal use,” says Moradi.

He has incorporated Vital’s AI tool development programme into its design and prototype manufacturing process, continuously trialling the latest tools, speaking with global experts, and collaborating with highperformance computing, data analytics and AI research facility, the Hartree Centre.

Moradi believes that every small to medium-sized business has the capability to create its own AI powered tools. “The kind of AI that most people want is a tool, one that preferably disappears, not behind a chat interface, but one that gets embedded in things we already do. It’s a tool that is so customised and bespoke that it serves our individual needs, preferences and the professional context in which we operate.”

Vital Auto – AI tools built in-house

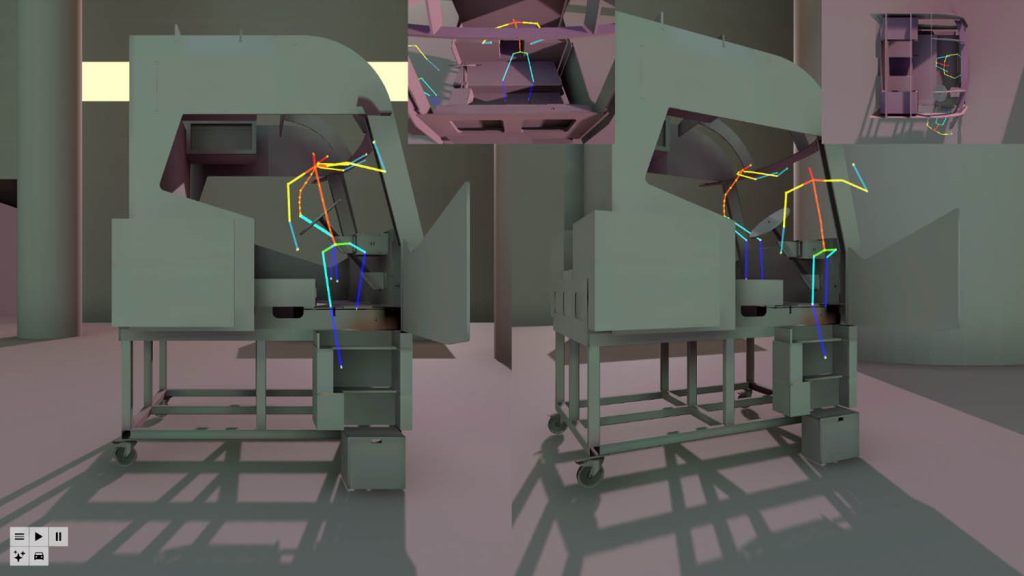

In that respect, employees at Vital are no exception. The team there has developed two proprietary tools: the AI-powered pose estimation tool Capture, and its complementary component, Eye Track; as well as the Vital AI Suite, an internal tool that is intended to simplify some of the information processing capture and analysis that complements Vital’s design production and prototyping activities.

Andy Shaw, a director at Vital, adds that as industry transitions into software-defined vehicle (SDV) architectures, vehicle design is no longer a static process.

“SDVs rely on over-the-air updates, digital twins and software-defined ergonomics. It’s a continuously evolving system where software updates, driver behaviour insights and real-world telemetry all influence performance and ergonomics, post-production,” he explains. “Having sophisticated tools that enable us to simulate human interaction, capture real-time feedback and refine UX dynamically is more critical than ever.”

Capture and Eye Track play a key role in this, by helping design teams validate ergonomic and interaction decisions, not just for the initial design, but also for continuous software-driven updates that defi ne the SDV experience. Capture’s role is to provide ergonomic precision for vehicle occupants by analysing body postures, movements, and contextual scenarios, in order to map ergonomic constraints and physical interaction flows. These are displayed in CAD at a later stage, so that designers can use the information accordingly.

By using ergonomic data combined with transcripts of participant conversations and the eye-tracking tool Eye Track, Vital can demonstrably prove user intent and actual usage in real time, with the ability to play back and analyse again. “It embeds evidence at every stage of evaluating and proposing design attributes and key decision-making, before something gets to the engineering phase,” says Moradi.

Recently, Capture proved its value on a project for zero-emission hydrogen truck company HVS Trucks. It was used during the iterative design evaluation stage to design a better, more aligned cab experience for drivers.

“Our work showed optimal placement of HMI screens, as well as the interior configuration and external points used during ingress and egress, and we used this to influence and feed back into the design during the course of our prototyping activity,” explains Moradi.

“The future of automotive design isn’t just about faster printers or sleeker clay models. It’s about building properties and systems where every iteration is a data point, every prototype a hypothesis tested,” he states.

For Vital, AI is no longer a buzzword, but a very real bridge between human intuition and computational precision during the design phase. And as the tools used evolve alongside AI technology’s growing capabilities, designers and engineers have a chance to shape these tools themselves, Moradi says. The end result? Unprecedented agility, fail-faster development cycles, deeper learning and fearless innovation.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here