These days we all take air travel for granted and give very little thought to the brave pioneers who sowed the seeds of modern aviation.

One hundred years ago, hot on the heels of the Wright Brothers and Louis Blériot, it was British engineers that were scrambling to be the first to ‘take to the skies’ and fly a circular mile in an all-British monoplane. The challenge was set by the Daily Mail to help kick start the British aviation industry, which lagged behind the US and Europe, and the newspaper put a prize of £1,000 up for grabs.

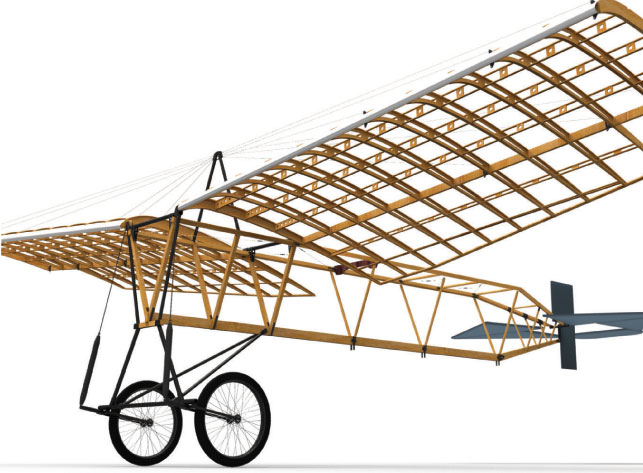

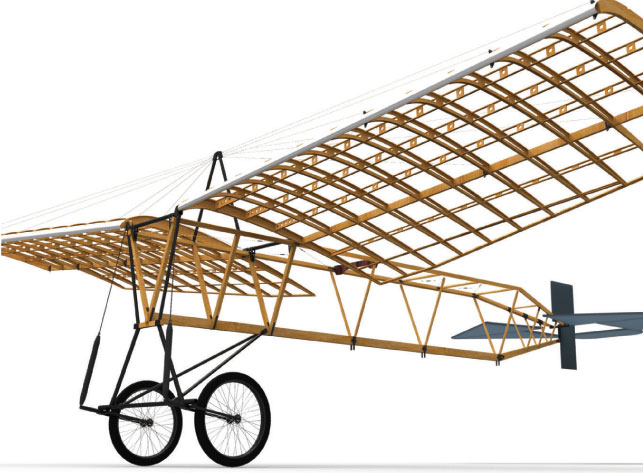

Replica monoplane, modelled in SolidWorks, and rendered with KeyShot from Luxion (image courtesy of DEVELOP3D’s Al Dean)

This was big money, but at a time when air flight was an avant-garde, if somewhat dangerous practice, the prestige of achieving such a feat was also a huge incentive.

One pioneering pair willing to risk their lives to scoop the award was Alfred Grose and Neville Feary who in 1909 set to work on building their own monoplane in a barn in the small village of Oakington near Cambridge.

Faced with stiff competition and huge engineering challenges their two man craft sadly never get off the ground and all their achievements were soon forgotten, a part of the village’s history. This was until local resident Nick Harrison, managing director of product design consultancy Round Peg, came across some information about the Oakington Monoplane, a discovery that would eventually lead to him to an ambitious project to recreate the legendary aircraft in his spare time.

The original Oakington monoplane – click through to see Nick Harrison with his replica Grose-Feary

“It was in 1998 when I discovered a copy of a hand written document, which gave details of the monoplane and the men that built it. I then found that someone in the village had a photo of it. From there I was hooked,” says an enthusiastic Harrison.

With little information available about the plane, Harrison’s first step was to try to build up a bigger picture of the two men involved. Grose and Feary had a good blend of aviation and engineering experience with Grose having first built his reputation in the motor trade, whilst Feary was an aeronautical instructor. To build the British monoplane the duo sourced components from all over England.

The 20 horse power (HP) four-cylinder air cooled engine was made by The Advance Motor Manufacturing Co. of Northampton, the mahogany propeller by Handley Page of London and the undercarriage constructed by Mr H V Quinsee of East Road, Cambridge.

In an article in the Cambridge Chronicle of 17th September 1909 a local journalist reports on how he came upon a large barn where he found the two “flying men engaged on a cigar-shaped machine.” In the interview Grose came across as a man confident in his design, but despite several attempts, the plane never managed to get off the ground. Generating enough power, while keeping the overall design light was a huge challenge. Although a Mark II of the monoplane was built, it was eventually dismantled in 1910 and Grose and Feary both left Oakington.

A flight of fancy?

Harrison’s interest in the legendary Oakington Plane started out as a research project, but as the years went by he became more and more embroiled in the history of this forgotten ‘flying machine’.

Every piece of information he uncovered gave him something new to research and in 2004 he set up a website to document all the information he had gathered so far.

His part time hobby soon became a real passion and he started to wonder whether he could actually build a replica of the monoplane. “It wasn’t long before I decided that if enough information could be found, the monoplane could be modelled in 3D,” he explains. “As time went by there became less and less reason why a full scale replica could not be built.”

With two more having joined his project – retired engineer and Oakington resident, Edgar Stearn, and practising engineer Phil Bailey – the trio finally went public with their plans and soon support came flooding in.

“After an article in our local newspaper in 2008, in which we made our intentions to build the replica clear, we were contacted by Terry Holloway of Marshall Aerospace who agreed to support the project,” says Harrison. “Since then we have had more than 15 companies and individuals that have offered help of goods or services in order that the project can become a reality.”

A wing and a prayer

Although Harrison and his team were attempting to resurrect a piece of history, they weren’t going to revert to using hand tools like the original designers. Instead they decided to utilise modern design tools and manufacturing techniques. “CAD was the natural choice as the quickest way to get to a finished replica,” explains Harrison. “The project depends on having spare time so, as with everything in the project, we need to be as efficient as possible.”

Photographs were taken into SolidWorks and, together with known dimensions, were used to build up a 3D model of the monoplane

With a handful of old photographs and some dimensions they started off by creating the wings. “The information used to reverse engineer the monoplane has been wing span, length, wing area and the three original photos I had,” he says. “In addition we have copied period practice and referred to drawings of a Blériot [Frenchman Louis Blériot was credited as being the first person to construct a working monoplane] for things such as the aerofoil section.”

During this process Harrison found it particularly useful to be able to bring a photograph into a SolidWorks sketch. “We started with a 1:1 outline drawing of a Blériot rib. We had that drawing scanned so we could bring it into a SolidWorks sketch,” he explains. “We then scaled it to suit the Grose-Feary chord rather than that of the Blériot. It was then just a case of tracing over with good geometry to produce a rib model.”

From there they sent the finished drawing to a CNC routing company, who within days had machined a full set of ribs from plywood. “The wings illustrate our approach,” says Harrison. “The ribs have been CNC routed and therefore can be produced in a fraction of the time that would have been taken to produce them by hand. We have also made a gluing press for the ribs, again CNC routed to the exact profile of the ribs.”

The wings and fuselage were finished in time for them to go on display at Marshall’s centenary celebrations in September 2009 – a happy coincidence considering that Grose and Feary were building their original plane in the same year that Marshalls started.

Get the motor running

The second stage of the project was to build a replica of the Advance V4 aero engine. In 1909 finding an engine capable of powering a plane was a major challenge for Grose and Feary.

“Engines in those days were fairly temperamental. You had to get the thing running in the first place and it would take some time to get it up to operating temperatures so that it could have full power,” says Harrison. “But then, because they had lightened it and removed a lot of the cooling fins, if you weren’t actually flying and doing 30 mph through the air, the thing would overheat. So you had about two minutes of opportunity to run this engine and try and get this pioneering engine to fly – and all at a time when you really didn’t understand aviation or anything related to it.”

The monoplane’s engine was made by the Advance Motor Manufacturing Co of Northampton, a company that not only produced its own motorcycles, tri-cars and fore-cars but also manufactured its own air and water-cooled engines. From the Cambridge Chronicle article, Harrison discovered that the company produced a 20HP Air Cooled V Four (2,290cc) aero engine. However, from photographs he could tell that the engine was in fact two V twin 9HP engines bolted together to give an output of 20HP.

The original engine from the monoplane was two Advance V twin 9HP engines bolted together to give an output of 20HP, as they were unable to source one, the team reverse engineered an original 1900s Advance motorcycle engine

After a fruitless search Harrison accepted that he could not get hold of any examples of this original engine. Unlike the wings, this time he felt that he would not be able to create a suitable replica solely from the photos and technical specifications he had uncovered. His next step was to find a motorbike engine that Advance had produced at around this time and reverse-engineer that in order to understand how the company made its engines, but this was easier said than done.

Through the vintage motorcycle club Harrison found there was one Advance motorcycle in existence, but the owner had already sold it to the National Motorcycle Museum in Birmingham. He then got a lead on another engine, but the owner was terminally ill so things went cold for a while. 12 months after he died Harrison picked up the courage to get in touch with his widow, but found that the engine had been sold and the new owner had moved to Australia. Finally, after two years of tracking it down Harrison got his engine.

The 3HP engine that Harrison acquired was of different bore and stroke to the aero engine, but all Advance engines of this time were of the same basic design, featuring automatic inlet valves and a one-piece cylinder head and barrel.

A number of different techniques were then used to reverse engineer the 3HP motorcycle engine. Firstly, the barrel was 3D scanned and then measurements taken off it. “The finished barrel model only used the scanned point cloud data as a guide, albeit a very useful guide,” explains Harrison, adding that any measurements taken off would probably deviate from design intent due to manufacturing inaccuracies.

The team also used a flat bed scanner to scan the profile of the cam. The image was then brought into a SolidWorks sketch, scaled to suit the measurement taken and then true geometry sketched over the top. “By reverse engineering the 3HP engine, I now understand the design style of Advance engines and can use that knowledge to reverse engineer and create the Aero Engine,” he says. “In addition, given that the 3HP engine is the only one of its type, reverse engineering it was an insurance policy as no amount of money could replace it if I don’t have drawings.”

Tune in, turn on

Harrison has some theories as to why the original Oakington monoplane engine couldn’t produce enough power for flight and believes they will be able to improve on it when they actually come to designing the replica engine.

One major advantage is that their engine will be machined to far better tolerances than could have been achieved in 1909. It will also use aluminium pistons over cast iron, which will save weight, and the ignition as well as the carburettor will be a modern design. However, as the team has managed to get hold of an original Brown and Barlow carburettor from 1909, they will see whether the engine can run on that first before opting for a modern alternative.

“We have decided that we will build the engine in the first place with automatic inlet valves [the same] as the original,” says Harrison. “If we find we need more power then we will convert the engine to mechanical inlet valves. It seems a better option to do something that would have been possible in 1909, rather than just bolt in a more powerful modern engine.” Then, as with the wings and fuselage, they will produce all of their own patterns for the castings using CNC mills and routers. “This will save not only time but a great deal of cost as well,” he adds.

Having overcome many barriers, Harrison finally has a supply chain in place to make the engine. “I went through 20 different foundries who told me you cannot cast thin cast iron fins down to 2mm. Well, it looks like there’s one there,” says Harrison smiling, as he points to a picture of the original engine. “They were doing it 100 years ago. It’s not that they couldn’t, it’s just that they didn’t want to, that was my attitude. Eventually we found a company that would do this for us.

“But we’re obviously going to take a short cut, we’re not going to get a pattern maker to make one of these by hand. We’ll be CNCing the patterns straight from the 3D data.”

Come fly with me

With the wings and fuselage complete, the team will then move onto the tailplane, cockpit and the undercarriage, which according to Harrison is not far from being finished. The final challenge will be the design and build of the replica engine.

However, due to aviation authority restrictions Harrison may never to able to see the Oakington monoplane fly. “In the UK, there are no experimental classes for aircraft so you either have something that is fully airworthy or not,” he explains. “You don’t have something that you might be able to hop in the confines of an airfield – unless we can twist some arms.”

To produce an aircraft with all the required structural analysis and materials fully certified would have increased the costs ten fold and as a hobby that was too prohibitive for the team. “We are looking at other countries and once we get the thing done can we take it somewhere else, says Harrison. “America is one place where they do have an experimental class. It might sound expensive to take this thing to America, but actually it’s a lot cheaper than building an airworthy aircraft in the UK. Put it in a container and have a week’s holiday!”

Harrison is determined not to let legislation get in the way of his dream and is hoping that the Oakington Plane will finally make its maiden flight more than a century after it was first conceived. With the dangers involved in taking a plane of this type high into the skies he would be happy just to be able to taxi and maybe ‘hop’ across the fields.

It is the least the new Oakington team can hope for considering all the time and passion that has been ploughed into this project. “Whether we succeed in getting the monoplane airborne or not, we will have produced a replica of a previously unknown and probably the first aeroplane to be built in Cambridgeshire,” says Harrison. “With that in mind I hope that we will have placed it in its rightful place in the history books.”

www.oakingtonplane.co.uk

Bringing back to life one of the original British monoplanes