Edwin Stokes

We provide a 3D printing bureau service in addition to offering bespoke digital manufacturing services. We also build complex manufacturing projects such as assemblies of multiple parts and soon we’ll be offering contract manufacture, such as manufacturing end-use parts, as that is an area we’re currently growing.

We operate in rural North Yorkshire in a contemporary office workspace shared with our sister company, Stage One.”

What are your weapons of choice?

Our Hewlett Packard Multi Jet Fusion 4200 is our main weapon of choice. It’s our most used and versatile machine, providing high quality nylon PA12 parts faster than anything else.

What technology/product couldn’t you live without in your workspace?

As a passionate cyclist, I wouldn’t be without my road bike! Commuting by bike sets me up for the day both mentally and physically.

What is missing from your toolset?

We have a great toolset right now but being a relatively new company that’s growing we’ll likely invest in new production management software.

Is there anything that would make your design process run smoother?

Fixing defective 3D files, planning 3D printing builds and managing capacity can be time consuming. We’re evaluating software from Materialise to streamline this which should improve our processes.

A section of a large prop for a theatre show emerging from the Massivit 1800

The Fortus 900mc is housed in one of Fluxaxis’ two lab spaces

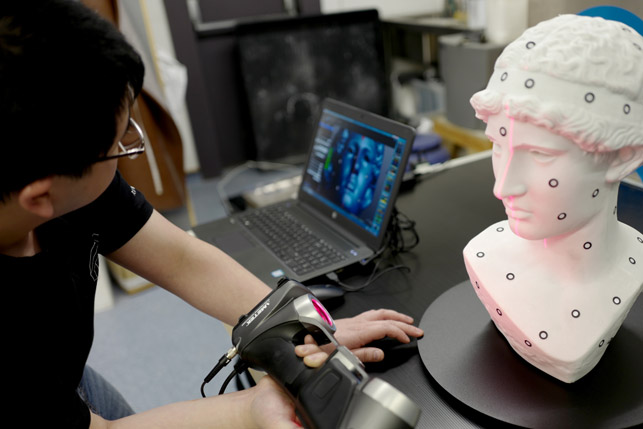

The team love the HandySCAN 700 – it’s fast, accurate and portable

Morning meetings in the spacious kitchen

Planning a build on the HP Multi Jet Fusion 4200 in its second lab space

Although office space is shared with Stage One, Fluxaxis has the best desks – close to the kitchen & meeting rooms

Edwin Stokes, director, Fluxaxis, Tockwith, UK

Default