Looking more like an organic exoskeleton than motorcycle, the Light Rider weighs in at just 35kg

In the aircraft industry weight saving is king. Less mass to lift into the air means less fuel, which means less cost and carbon emissions. So it benefits the airline, the passenger and the planet.

Being one of the biggest aircraft manufacturers, Airbus knows this all too well. And although it still largely utilises traditional manufacturing methods, substantial resources have been dedicated towards advanced manufacturing technologies including additive layer manufacturing (ALM).

Here components are optimised during the design process to achieve less material waste and improved weight savings.

The advantages of such 3D printed parts for the aircraft industry are obvious – and Airbus is currently testing such parts on its aircraft (see box out below) – but many other industries from robotics to automotive and medical can also benefit.

So in 2013, Airbus set up APWorks, a 100% subsidiary with a production facility in Munich, to not only further explore this technology and work on innovative projects for Airbus Group, but to operate as an independent company offering expertise in design, materials and 3D printing.

“The perfect interplay of design, material and printing does not only lead to reduced weight, cost savings and the integration of increased functionality into parts, it also revolutionises the design and manufacturing process,” says Angela Gruenewald, APWorks marketing manager.

APWorks’ proprietary material Scalmalloy is a second generation aluminiummagnesium-scandium alloy developed for very high strength extrusions

However, with customer projects often being confidential, APWorks can’t tangibly showcase the possibilities of parts that have been designed specifically for ALM. So it hatched an idea for an internal project that would allow it to do just that. The product decided upon was an electric motorcycle.

“We decided on a product that people would already have a stereotype in mind of how it may look. They know what to expect of a bike and how heavy it is. But when they see our design, they’ll wonder how it is possible to design and produce such a thing,” says Gruenewald.

So having produced what APWorks claims to be the first 3D printed motorcycle, the rather aptly named Light Rider weighs in at just 35kg, of which the frame is a mere 6kg. And although it may be 30 per cent lighter than a motorcycle with a traditionally manufactured frame, it’s just as strong or possibly more so although may not look it.

Advanced materials

This project also provided APWorks with the opportunity to showcase its own proprietary material – Scalmalloy – in the construction of the frame.

Specifically developed for series production using ALM technologies, this aluminium alloy features mechanical properties that make it ideal for use in lightweight robotics, automotive and aerospace applications.

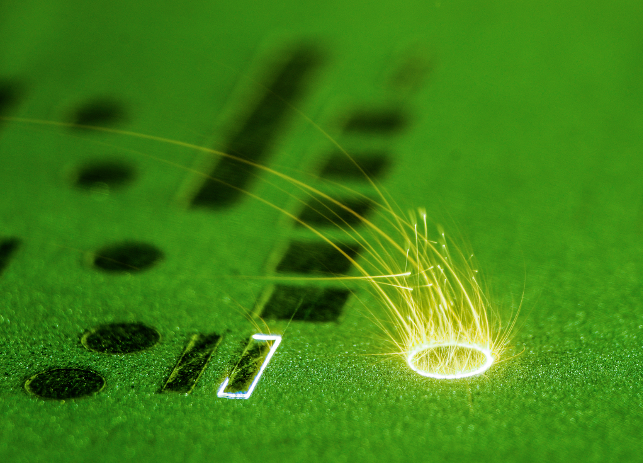

In the additive layer manufacturing process, a laser melts powdered Scalmalloy into thousands of layers

“To make radical progress in lightness, strength and ductility, we need advanced materials which will achieve their full potential when combined with advanced manufacturing. This is what we can do with Scalmalloy and for the Light Rider it means a frame of unprecedented weight saving,” continues Gruenewald.

The Light Rider project also provided the opportunity for APWorks to reveal how it goes about designing parts specifically for the ALM process. And to do this its engineers use a simulation tool from Altair called OptiStruct during the concept phase of the development process in an approach known as topology optimisation.

Essentially this is the ability to optimise material layout within a given design space, for a given set of loads and boundary conditions in order to achieve the required performance targets.

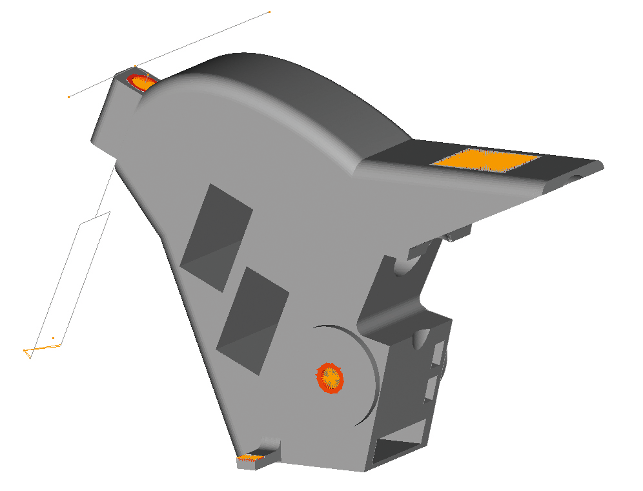

The first stage of the topology optimisation process using Altair’s OptiStruct is to defi ne the design space

As Mirko Bromberger, Altair’s director of marketing and additive manufacturing strategy, explains, “This branch of computer aided engineering (CAE) involves the use of intelligent technologies that give a designer guidance on where material is required and where it can be removed to leave a structure that exhibits the required performance targets but at a signifi cantly lower weight than relying on intuition or experience alone.”

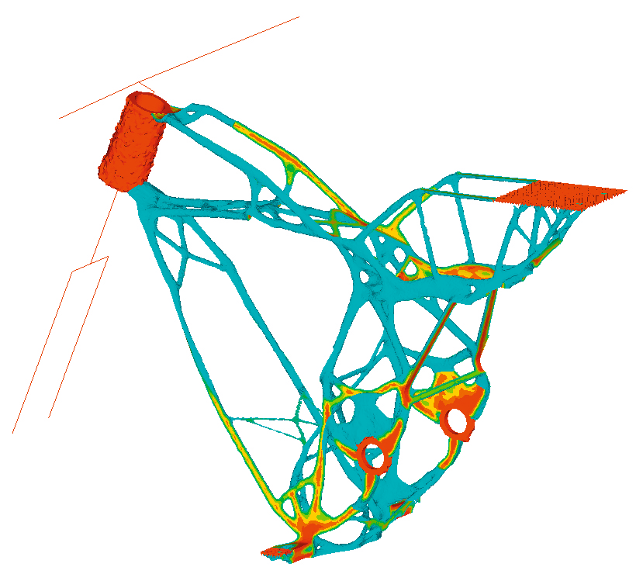

The resulting optimisation

“The downside is that the organic shapes that the process creates have not traditionally been easy to manufacture, causing engineers to add mass back into the design to meet the practicalities of the production process. However, when optimisation techniques are coupled with additive manufacturing, it is possible to produce a structure that’s far closer to the optimum solution,” continues Bromberger.

The design engineers will then use these results to refine the design

Simulation driven design

In this simulation driven design process, APWorks’ engineers needed to firstly define the design space.

This refers to those areas where geometry cannot be adjusted such as fixing points or access holes. Then all known loads and boundary conditions were added.

APWorks used a Cafe Style Racer as the design guideline and researched information on typical load cases for motorcycles.

“Into OptiStruct we added some boundary conditions. We thought about all kinds of things – what’s located where on a bike, how big it is, what’s the wheel base, what happens when you ride it,” describes Gruenewald.

Additionally, as this was designed specifi cally for the ALM process, the engineers could create a hollow frame to not only further reduce mass but also provide a means of hiding cables and pipes. However, APWorks points out that the thin and complex structure achieved is only possible with very strong and lightweight materials like Scalmalloy.

“With Scalmalloy you can have lower wall thickness but still have the same strength if you compare it to other materials used for metallic 3D printing,” adds Gruenewald.

Having inputted all this information into OptiStruct, APWorks could then programme the algorithm to use bionic structures and natural growth processes as the basis for developing the frame. The software calculates the optimal load curve and where material has to be placed in order to meet the required stiffness characteristics. And as it starts to take shape in the software, the design looks more like an organic exoskeleton than motorcycle frame.

“But you just get a proposal from the software and the next step is that our design engineers interpret these optimisation results. For instance, they have to refine it further in order to get a printable and appealing geometry,” says Gruenewald.

The resulting design is again validated via an additional finite element analysis to confirm the required stiffness.

This is carried out using Altair’s HyperView tool.

Challenges ahead

However, a challenge during the design process was considering how to divide the frame up for printing as it couldn’t be printed as one complete structure. The engineers decided to create 14 separate sections that would be able to withstand all the loads.

The engineers also had to consider how the various parts would be assembled once printed. “With customer projects we know all these boundary conditions – we know where the part will be mounted at which point and what diameter the screws are or how it will be assembled to other parts. But for our motorcycle, it was really challenging to design everything that you can assemble afterwards and not encounter any problems with screws, cable or routing,” describes Gruenewald.

Happy with the final design, it was ready to send the files to the EOS selective 3D laser printing system, which uses a laser to melt powdered Scalmalloy into thousands of layers, with each layer being just 60 microns thick.

Once all the parts had emerged from the printer, they were TIG (tungsten inert gas) welded together, a process that uses a tungsten electrode to produce the weld and favoured in this project due to the greater control it offers the operator over the weld.

According to Gruenewald, it took three weeks to print and assemble the Light Rider. Once complete, it was ready to ride and with a 6kW electric motor can reach 80km/h in a few seconds.

“Those who have seen it are impressed by the design because it is new and innovative. And they are even more impressed when they can easily lift it up. But the real excitement comes when they ride it and feel the speed and strength of the motorcycle.

“They may have a feeling that there is material missing but in the end it is optimised for the loads so it’s just a new way of designing things,” she says.

APWorks is capable of creating series production at its facilities and so is currently offering a production run of 50 Light Riders for sale at €50,000.

The Light Rider has a 6kW electric motor powering it from 0 to 80km/h in just seconds

More to come

Although Light Rider may be an ostentatious display of what is possible with topology optimisation software, lightweight materials and 3D printing, APWorks has worked on some equally interesting but perhaps less glamorous projects including a bionic aircraft cabin partition (see box out below) and is also currently developing the first fully 3D printed liquid-to-liquid heat exchanger that can be used for both robotic and automotive applications.

But according to Gruenewald, the opportunities for optimised 3D printed parts are endless for any industry.

“It’s exciting for designers because they can completely rethink how they design products,” she says.

“Right now they have all these limitations in mind dictated by what is possible in manufacture, but with 3D printing they can design freely and can completely rethink this process. It is certainly exciting.”

APWorks technical manager Daniel Schneider will be talking at the SolidThinking Converge 2016 conference in Essen, Germany, on 20th – 21st September. The Light Rider will also be on display during this event.

He’ll then be talking again at the TCT Show + Personalize at the NEC in Birmingham on 29th September.

Taking flight with 3D printed parts

Together with Airbus, APWorks has developed what it refers to as the world’s largest metal 3D printed airplane component — the Bionic Partition.

This partition panel is essentially the wall that divides the aircraft cabin and supports the jump seats that the flight attendants sit on during takeoff and landing.

The current design, which has been flying in the A320 successfully for decades, is a strong and lightweight component made from a honeycomb composite but Airbus wanted to explore what could be possible using topology optimisation and additive manufacturing technology.

“An algorithm that uses the ‘biological algorithm’ of slime mould was developed to link critical connection points in an airplane partition. Then a process of bio computation was run that generates, evaluates, and evolves tens of thousands of design options,” explains Angela Gruenewald, APWorks marketing manager.

Collaborating with Autodesk, Airbus utilised its cloud computing service to generate all these design alternatives.

The component also marks the first time that APWorks’ proprietary material Scalmalloy has been used on large scale inside an aircraft component.

The new partition features far less material than its predecessor and also weighs 25kg less.

Airbus estimates that just this component will save 465,000 metric tonnes of CO2 per year.

The Bionic Partition is currently undergoing 16G crash testing as part of the process for certification and integration into the current fleet of A320 planes.

3D printing the Light Rider electric motorcycle

Default