Vario by Velux is all about bespoke daylight solutions for the roof, creating bright indoor living environments while simplifying the relatively complex building process for customers. Velux wanted to create an online product configurator that would make putting together your requirements for an intricate product like a rooflight as easy as it is for a new car or a new pair of running shoes.

“Our ambition was to make a flexible online configurator where customers could freely design their products and select/deselect all features as they please,” says Carl Frederik Gierding, business manager of Vario by Velux. But with more than 100,000 different product combinations possible, this was not an easy task.

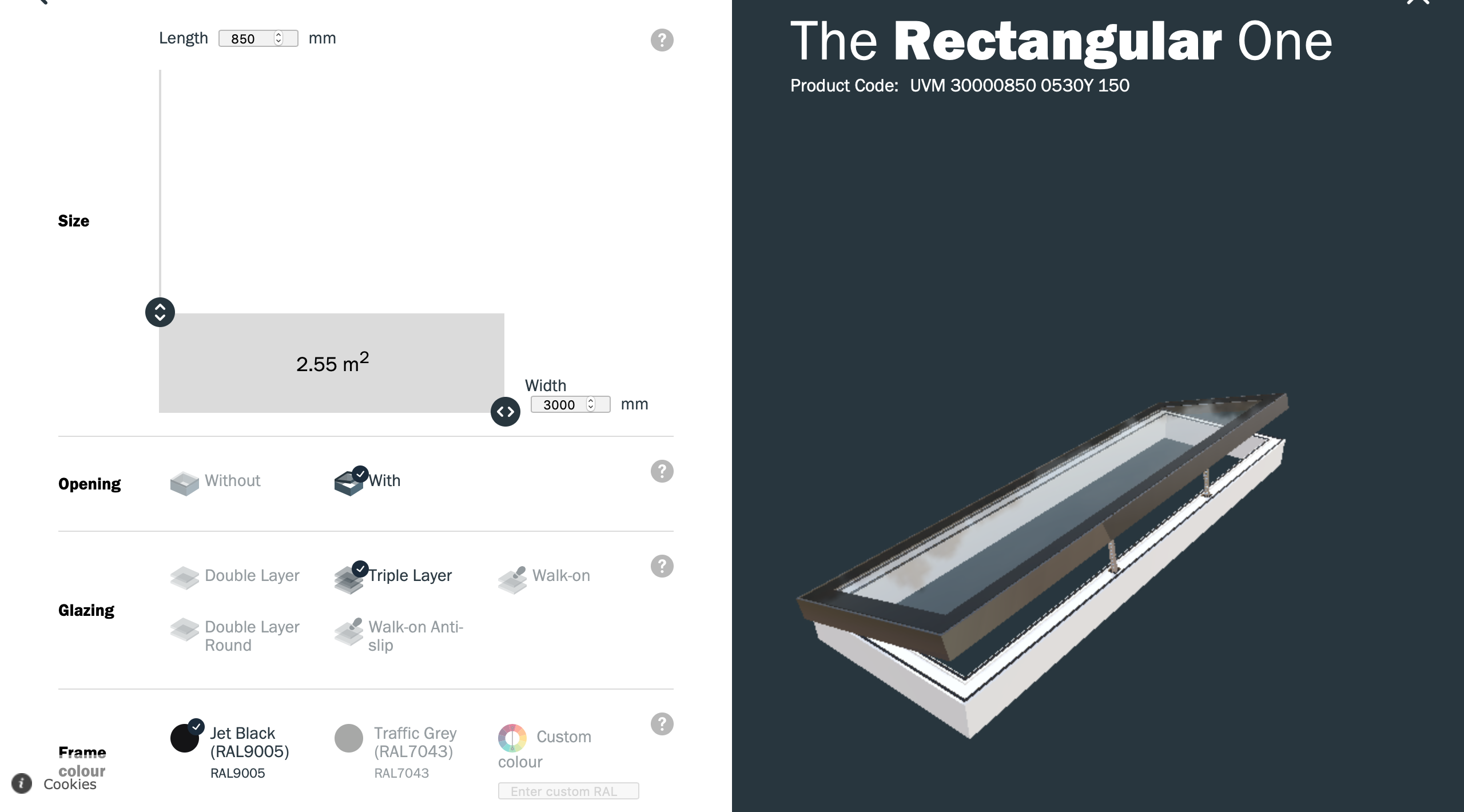

With regards to the content of the configurator, the Velux team looked at selections, real-time pricing and 3D modelling; including all the configurable product parameters, mapping the constraints of its bespoke product programme.

The constraints were coded into the back-end of the system and the configurator linked to the Vario price calculator in order to present the actual product price in real time during the customer configuration.

Additionally, the configurator was linked to all of Velux’s 3D models, designed in AutoCAD and turned into a 3D web version in JavaScript with support from by a WebGL real-time 3D engine called Babylon.JS. These are simultaneously displayed in real time as the customers play with their design.

After drafting ideas for the configurator, Velux tested the design with its users to gather as much early feedback as possible.

Velux – clear guidance

Despite all this automation, the human touch still counts. Once an order has been made via the configurator, Velux customer service staff then pick up the phone to the customer within 24 hours, to run through their order with them.

According to Gierding, this is an important step to ensure the configuration matches the project for which it is intended. “It allows us to correct any misconfiguration, which we believe ultimately will improve the customer experience,” he explains.

Despite it being a complex and relatively time-consuming process to build a configurator for bespoke rooflights, Velux sees great value in it for customers and partners, but also for itself.

“By letting our customers configure the specific products they see fit for their specific home, we get a chance to understand what our customers are actually looking for,” explains Gierding. “It is a magnificent way for us to tap into customer-centric innovation and greatly helps with future product development opportunities.”

The ability to spot customer demand early – even from abandoned projects online – can help drive future product lines.

Velux – one up front, two at the back

The configurator is built to deliver data that is easily understandable for the manufacture of the windows, with human interaction relatively confined to a manual quality assurance process before the data is released for production.

With various shapes in Velux’s product portfolio – from traditional rectangular frames, to round porthole-style openings – it was a challenge to decide on whether to make one or a number of configurators for each style.

On the one hand, the customer experience had to be as seamless as possible, without requiring customers to switch between configurators. On the other, size parameters were completely different for the differenty types, being width and length versus diameter.

Velux’s solution to this challenge was to make two configurators in its back end, but only one configurator in the front end, which leaves the complexity with the design team and ensures a better experience for the customer.

Defining the order of the feature selection proved relatively complex, too, as compromises between design and user experience needed to be found. “From a technical point of view, we had some choices we would like the customer to make early in the process, in order to be able to provide a narrower set of possibilities and thereby reduce the amount of ‘constraint messages’,” says Gierding.

“However, it did not seem intuitive for the customers to make the more technical choices early in the process. The outcome was that we listen to our customers!”

This then created a new challenge; namely, how to easily communicate to a customer that they have reached a limitation or constraint? Initially, it was a challenge for Velux to make the constraints clear and simple for end-users.

“We did not want the customer to meet constraints throughout the process, but we also wanted the customer to be able to design and configure freely, which is a tough balance to strike with a complex product programme,” explains Gierding.

This is only the beginning of what Velux has planned for its product configurators. With a foundation to build on, the next step will be defining new parameters and features.

“What has been our largest challenge has actually been all the add-on elements we plan to add, such as blinds and sunscreening products, rain sensors, remote controls, Smart Home indoor control etcetera,” says Gierding.

The current plan is to add a step into the existing configurator that will focus on these add-on elements or features, which has added benefits for the brand. “When we know the product configuration of the customer, it becomes easier to offer the perfect add-ons,” he says.

The final configurator combines the technical expertise and boundaries of Velux, while supporting a customercentric approach – all the while creating a window through which to gaze upon customer demands and forecast future trends.