By the mid 1960s, the world was in the grip of ‘Beatlemania’. Four Liverpudlian lads were causing mass hysteria, belting out tunes like ‘Love Me Do’ and ‘Ticket to Ride’, as they blazed a trail for popular music.

That signature Beatles chime and ‘jangly’ sound was projected through Vox guitar amplifiers, which became almost as iconic on stage as the Fab Four.

Fast forward 60 years, and a classic AC30 Vox amplifier, the model that Paul and John used, stands besides some of the brand’s newer models in a soundproof room at its Milton Keynes headquarters.

The technology inside the newer products may be completely modern, but the styling is virtually the same as their predecessors, with a retro cabinet design and identical gold Vox-branded logo.

“We are very proud of our heritage and one of the things that makes us completely unique is our trade dress – the gold logo against a black panel, the gold T-bar and the brown diamond grille cloth,” says Dave Clarke, R&D manager at Vox Amplification.

“At a music festival like Glastonbury, I can spot a Vox amp on stage from a mile away, because even if you can’t make out the logo, you can still see the black, gold and brown.”

Reviving the brand

If Vox was a superpower in guitar amplification in its 1960s heydey, by the 1970s, things had started to go awry.

With its founders experiencing financial problems, the company was handed from owner to owner. That resulted in inconsistent quality control, until it was acquired by the Japanese synthesizer company Korg in 1992.

Realising that the brand was hanging on by a thread, and only because people still associated it with the success of its earliest models, Korg decided to reintroduce the classic line-up, including the AC30.

When Clarke joined the company in 2004 as a development engineer, his first task was to design the AC30BM, a limited-edition amp for Brian May of Queen, as part of Vox’s Custom Classic series.

“We did a limited edition of just 500 pieces globally of this special amplifier for Brian May. What was special about it is that it had no controls except for a single knob for volume.

He told us that, ‘I plug in, I turn up and everything else is maxed out, so I only need one knob’. It looked quite funny – a huge control panel, with only one knob and two switches,” Clarke recalls.

“Actually, it was a very exciting time to join the company, because it was so new and they were relaunching everything. They didn’t have a big product line-up and it was very motivating as a younger lad to join in,” he adds.

On the subject of famous customers, Clarke and I are sat in what Vox refers to in-house as its ‘Artist’s Suite’. The walls are adorned with framed photographs of artists that have used the company’s amps, including The Beatles, The Kinks, Foo Fighters, U2 and The Rolling Stones. When visiting, it’s here that guitarists are brought to chat about their amp requirements.

Clarke says that he tries not to get too blasé about who comes to see them, as there have been a few famous faces over the years, Edge from U2 for one.

“Basically, Edge’s favourite amp from 1964 is falling apart but it has a very unique sound. I had to find out what makes it so special and having travelled to the amp to discover its secrets, Edge then asked us to make four custom amps, which I handmade myself. I’m a bit of a U2 nut, so it was a fun collaboration for sure,” he says.

Vox – team players

The Vox design team in the UK is pretty small, consisting of just Clarke and his colleague Phil Scarffe, senior development engineer, who are led by managing director, Ian Doggett. Between the two of them, they design the majority of tube-based Vox products, most of which are engineered from the ground-up, including the packaging, as well as the drawings and copy for product manuals.

“We are involved in the electronic design, industrial design, mechanical design, all the production drawings, designing all the silk screens, packaging artwork, the packaging itself… Everything you can imagine in the amp, we’ve either had a hand in, or have designed the whole thing. So every little detail is ours. It’s good and bad, because you can screw something up and then that’s your fault and you have to take it on the chin. But we found that for us, it’s a necessity to work this way because we are a small team and don’t have the luxury of farming stuff out to someone else. It’s busy, but I like it,” smiles Clarke.

Shrinking the super beatle

One of the most recent products the team has designed is the Mini Superbeetle. In fact, Clarke is not long off the plane from having launched it at Summer Namm 2018, a global music trade show held in Nashville.

The original ‘Super Beatle’ amp, as the name suggests, was used by the Beatles to make them heard above the increasing size of the crowds at their concerts as their popularity soared. Designed as a classic stack set, the Vox AC100 amp featured a whopping 100 watt head that powered a separate speaker cabinet below, housing the 4x 12-inch speakers.

“The Beatles wanted to plug their guitars in and didn’t really care that much how it sounded, it just needed to be loud. Now, in this day and age, no one needs a lumbering 100 watt amplifier with 4x 12-inch speakers. But what people do love is having that iconic imagery of the speakers behind the band,” says Clarke.

“So we thought about doing a modern-day take on this huge iconic amp and making it accessible to everyone. That was basically the inspiration for what became nicknamed as the Mini Superbeetle or MSB25.”

Speeding up the design

The Mini Superbeetle is the first product at Vox to be designed entirely in Autodesk Fusion 360, a cloud-based platform for product development.

“Although we were using Inventor in the office, I’d been using Fusion for almost three years for personal projects at home. It was great, because on an enthusiast’s license, it doesn’t cost anything, it’s super powerful and you can do fancy renderings, etcetera,” says Clarke.

“I didn’t use it for work, because it was still missing a few things. But Autodesk has been nudging it in the right direction and what tipped it over for me was finally when they introduced the sheet metal environment. Even though it was in its infancy still, it was enough for me to be able to get on with what I was doing.”

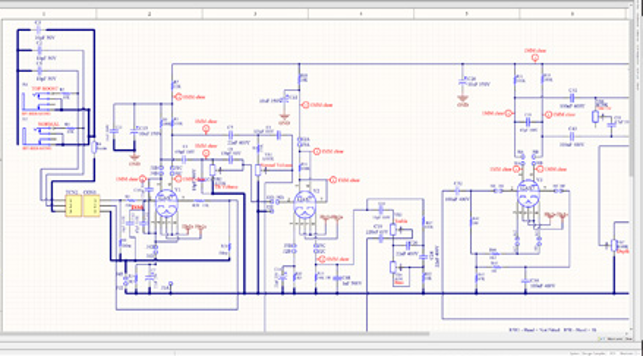

The hope was that Fusion would speed up the product development workflow on the MSB25. The entire product was created using Fusion, apart from the printed circuit boards (PCB) and schematics. These were handled by Clarke using Altium Designer, a PCB and electronic design automation software package.

“I had to design everything. The Bill of Materials (BOM) had to be complete, from the smallest component all the way through to the biggest one.

“So for me it did speed things up, because with Fusion you work from the component level, rather than assemblies and sub assemblies and sub parts, etcetera. You have to think of the original assembly as one component and everything is a sub-component of that. This working within one environment – instead of jumping back and forth between the part and drawing environments – worked really, really well,” he says.

Fusion aids collaboration

Apart from speeding up the actual design itself, Fusion 360 also helped them collaborate more effectively with the Korg manufacturing team in Vietnam, which in turn helped hurry things along.

“Key for me was being able to show them my design intent. By sharing a link to the Fusion model, which is obviously password-protected, they could always see the latest version of the design. And if there was ever any confusion, they could explore the model themselves just through a browser, without having to ask me simple questions,” says Clarke.

“Time zones can also work against you sometimes, because you’re trying to collaborate with someone who is nine hours ahead of you. They’re getting ready to go home as you come in, and it can really delay things. Whereas, because they were able to access the design and investigate issues themselves, it meant that they weren’t necessarily waiting for me on an answer.”

The Mini Superbeetle was also one of the first products to incorporate Nutube, a new vacuum tube developed by Korg that creates the characteristic tube sound for which Vox became known.

“In the 1970s, to the demise of Vox, the decision was made to switch from vacuum valves to solid state, thinking that modern tech would replace valves. It didn’t – and as a result, the amplifiers didn’t sound as good, as there wasn’t that same rich harmonic content you get with a vacuum tube.

“So Nutube is a modern-day take on the vacuum tube – the first innovation in vacuum tube technology since the 1970s, pretty much. It’s perfect for getting tube tone, but without all the bad sides of vacuum tubes, in that it runs cool, it’s small and it’s low-powered,” explains Clarke.

Vox – 3D printer workhorse

Throughout its design process, Vox makes extensive use of its in-house 3D printers to quickly explore ideas for custom parts, as well as to verify the mechanical properties of a part before committing to tooling. Its main workhorse in the workshop is the Form 2 desktop 3D printer from Formlabs.

“Specifically for the MSB25, I used it when designing a new custom knob, but apart from prototyping, we also find it very useful for making jigs,” describes Clarke.

“One of our tests is a tilt test, so you have to make a platform for something to sit on and rather than sawing out a bit of wood and hoping that it’s about right, we can make a 3D printed plastic part and stick it onto a wooden plank and we know that it’s exactly 15 degrees, or whatever the angle needs to be.”

Vox is very rigorous when it comes to testing and before the button is pressed on mass manufacture, products go through a very strict design verification process to ensure that the company delivers products of the utmost quality and robustness.

Says Clarke: “We test everything to destruction and probably go over and above the tests we should do. The process to get it past our Japanese heads of quality control is very tough. I’ve been doing this job for 14 years and it’s just as tough today, but the products we end up with are incredibly robust and we find that the number of field failures are far less than they used to be in the early days.”

Vox -small but mighty

With the MSB25 being manufactured in Vietnam, Clarke is working on the packaging design and creating drawings and copy for the user manual. “Vox has a core manual department that does the layout of everything, but I have to supply all the line drawings and explain what every single control does. This is then translated into five different languages,” he explains.

The Mini Superbeetle may be small, standing at just under 60cm tall and weighing in at under 9kg, but it certainly caught the attention of visitors at Summer Namm.

“People definitely commented on its looks – they love the chrome stand that harks back to the original and the head that fits perfectly on the cabinet – but it’s the sound that gets them really excited,” says Clarke.

“It’s the way we’ve tuned the cabinet, the custom design speaker that we had made by Celestion, the design of the circuit, the power amp, the NuTube… Everything is designed as one system to give a performance that is surprising for something so tiny.

Hopefully, this excitement now translates into sales.”